Octavia Mk1

Note

Note

|

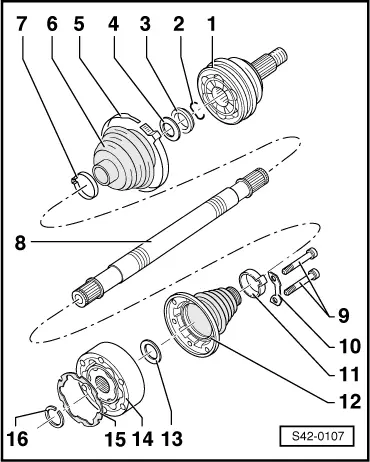

| 1 - | Outer CV joint |

| t | must be replaced completely |

| t | removing → Fig. |

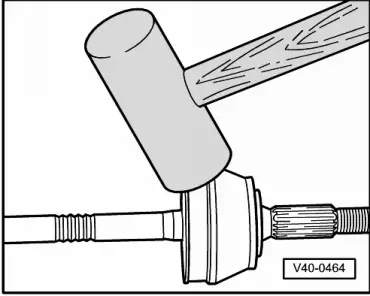

| t | install: drive onto the shaft with a plastic hammer until the compressed circlip expands |

| t | grease → Chapter |

| t | check → Chapter |

| 2 - | Circlip |

| t | replace |

| t | insert into the groove at the shaft |

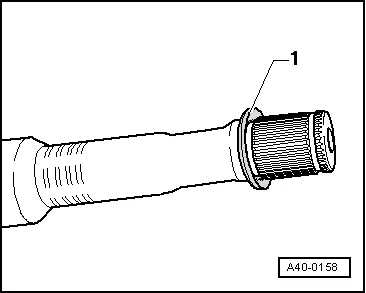

| 3 - | Thrust ring |

| t | Fitting position → Fig. |

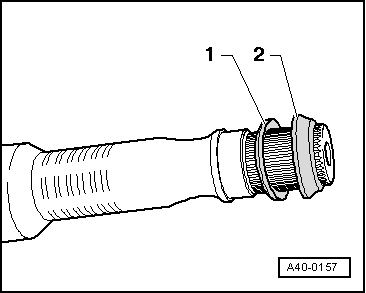

| 4 - | Disc spring |

| t | Fitting position → Fig. |

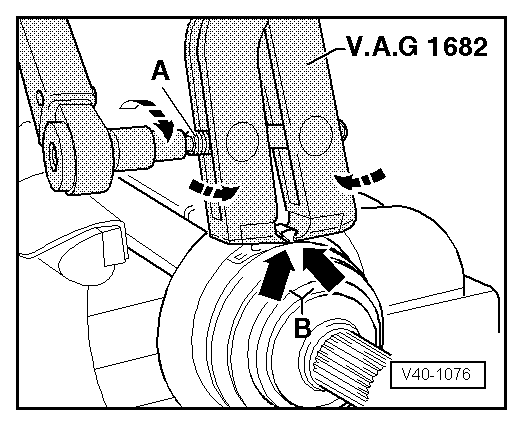

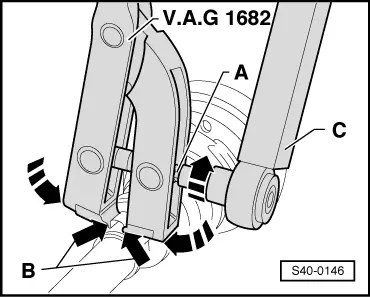

| 5 - | Open warm-type clamp |

| t | replace |

| t | tension with tensioning pliers, e.g. -V.A.G 1682- → Fig. |

| 6 - | Joint boot |

| t | Material: Hytrel (Polyelastomere) |

| t | inspect for tears and chafing points |

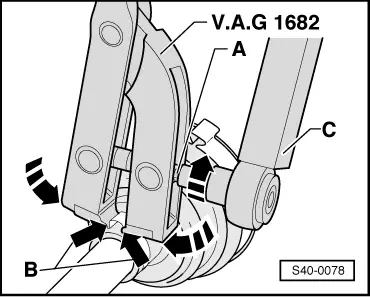

| 7 - | Open warm-type clamp |

| t | replace |

| t | tensioning → Fig. |

| 8 - | Drive shaft (solid shaft) |

| t | Assignment → Electronic Catalogue of Original Parts |

| 9 - | 39 Nm |

| t | M8 x 48 |

| 10 - | Shim |

| 11 - | Open warm-type clamp |

| t | replace |

| t | tensioning → Fig. |

| 12 - | Joint boot for inner CV joint |

| t | Material: Hytrel (Polyelastomere) |

| t | inspect for tears and chafing points |

| t | remove with a drift |

| 13 - | Disc spring |

| t | Fitting position → Fig. |

| 14 - | Inner CV joint |

| t | must be replaced completely |

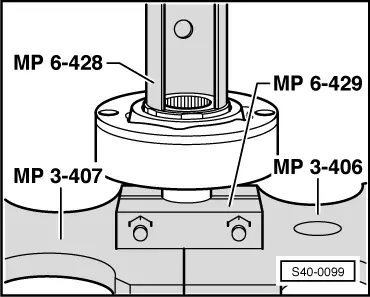

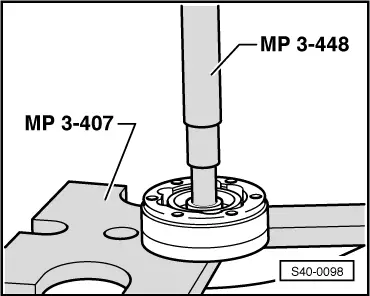

| t | pressing off → Fig. |

| t | pressing on → Fig. |

| t | grease → Anchor |

| t | check → Chapter |

| 15 - | Gasket |

| t | The adherend on the inner CV joint must be free of grease and oil! |

| t | replace |

| t | Remove the protective foil and stick the gasket into the inner joint |

| 16 - | Circlip |

| t | replace |

| t | remove and install with sprung pliers, e.g. -VW161 A- |

Note

Note

|

| Grease | of which in: | ||

| Outer joint | Total amount | Joint | Joint boot |

| Ø mm | [g] | [g] | [g] |

| 90 | 90 | 40 | 40 |

| Inner joint | |||

| 100 | 120 | 50 | 70 |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|