Octavia Mk1

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

| Tightening torque: |

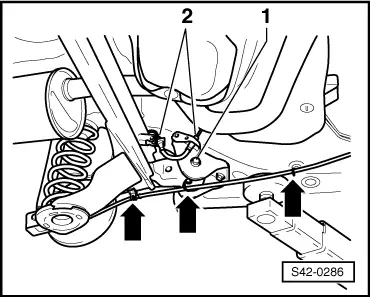

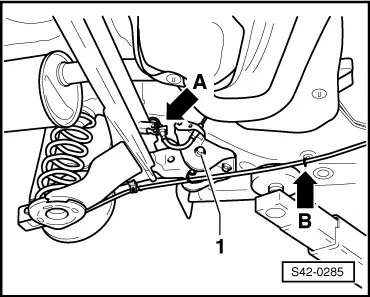

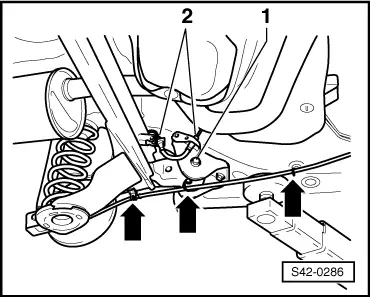

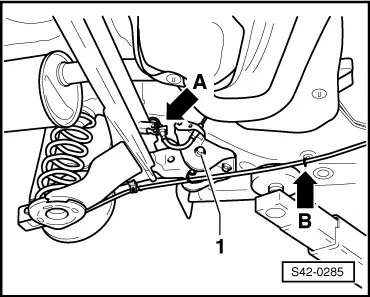

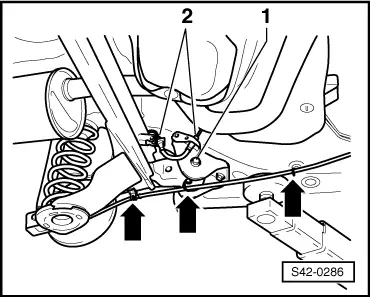

Rear axle to bearing bracket for axle

| 45 Nm + 90° | ||||

Bracket of rear axle to structure

| 30 Nm + 90° | ||||

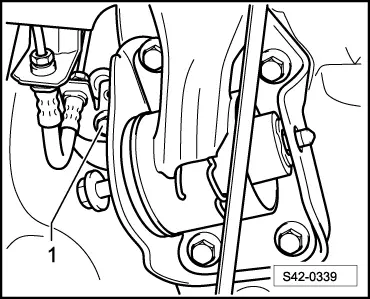

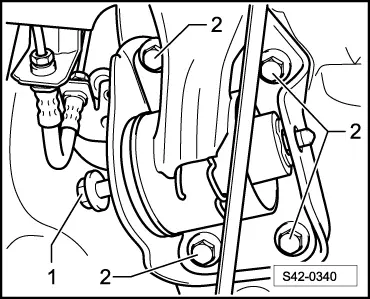

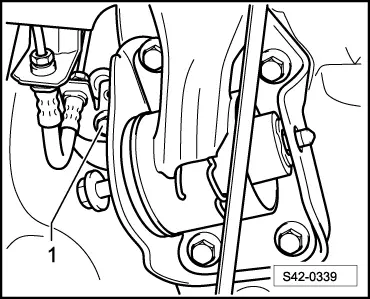

| Brake line holder to vehicle body | 16 Nm | ||||

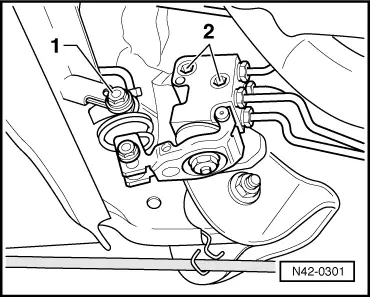

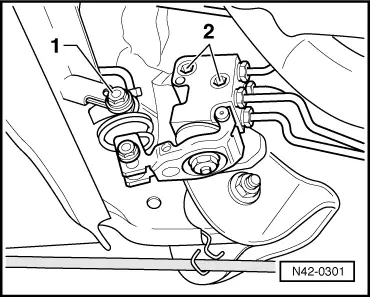

| Screw for brake-power regulator | 16 Nm |

Caution

Caution