Octavia Mk1

| 1 - | Wheel screw, 120 Nm |

| 2 - | 4 Nm |

| 3 - | Brake disc |

| 4 - | Cap |

| t | replace after each removal |

| t | press off → Chapter, - Pos. 5 |

| t | drive in → Chapter, - Pos. 5 |

| 5 - | Self-locking twelve-point nut 70 Nm +40° |

| t | replace after each removal |

| 6 - | Wheel hub with wheel bearing and pulse rotor |

| t | only on vehicles with ABS |

| t | The wheel bearing and the wheel hub are fitted together in one housing |

| t | this component is maintenance-free and requires no clearance adjustment; adjustment as well as repair work are not possible |

| t | removing and installing → Chapter |

| t | must be replaced completely |

| 7 - | 30 Nm + 90° |

| t | replace after each removal |

| 8 - | Cover plate |

| 9 - | Holder for hand-brake cable |

| t | replace |

| 10 - | Hand-brake cable |

| 11 - | 45 Nm + 90° |

| t | replace after each removal |

| t | when tightening the screw, the axle body must be in the horizontal position (unladen condition) |

| 12 - | Self-locking screw, 30 Nm + 90° |

| t | replace after each removal |

| t | if the thread of the weld nut is damaged, it can be repaired using Heli-Coli threaded insert; while paying attention to the fitting instructions of the manufacturer |

| t | the rework of the thread for the weld nut is permissible on maximum 2 screw points per axle |

| 13 - | Self-locking nut |

| 14 - | Mount for rear axle |

| t | check the overall track of the rear axle after installation and adjust if necessary |

| t | avoid slackening in order to remove the rear axle |

| 15 - | Holder for hand-brake cable |

| 16 - | Rubber-metal bearing |

| t | removing and installing → Chapter |

| 17 - | 20 Nm + 45° |

| t | replace after each removal |

| 18 - | Balancing weight |

| 19 - | ABS wheel speed sensor |

| t | only on vehicles with ABS |

| 20 - | 8 Nm |

| 21 - | Axle body |

| t | The locating face and the threaded holes for axle studs must be free from enamel and dirt |

| 22 - | bottom base |

| 23 - | Coil spring |

| t | removing and installing → Chapter |

| t | check for paint damage, if necessary eliminate paint damage |

| t | Assignment → Electronic Catalogue of Original Parts |

| t | per rear axle only use helical springs of the same make |

| 24 - | top base |

| t | installing → Anchor |

| 25 - | 40 Nm + 90° |

| t | replace after each removal |

| t | insert from the outside of the vehicle |

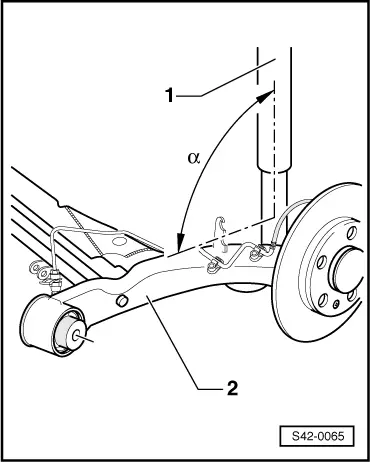

| t | when tightening, take the installation angle of the rear axle to the shock absorber into account → Fig. |

| t | While the vehicle is standing on its wheels, load the luggage compartment with approx. 100 kg and tighten the screw |

| 26 - | Self-locking screw, 30 Nm + 90 |

| t | replace after each removal |

| t | if the thread of the weld nut is damaged, it can be repaired using Heli-Coli threaded insert; while paying attention to the fitting instructions of the manufacturer |

| t | the rework of the thread for the weld nut is permissible on maximum 2 screw points per axle |

| 27 - | Shock absorber |

| t | can be replaced individually |

| t | removing and installing → Chapter |

| t | Assignment → Electronic Catalogue of Original Parts |

| t | disposing of → Chapter |

| t | Inspecting the shock absorber → Chapter |

| t | per rear axle only use shock absorbers of the same make |

Note

Note| Shock absorbers are not to be repaired. |

| 28 - | Self-locking nut |

| t | replace after each removal |

| 29 - | Axle stud |

| t | Straightening work is not allowed! |

| t | Re-cutting the thread is not allowed |

| 30 - | Protection against stones |

| 31 - | Fixing element for protection against stones |

| t | Protection against stones included in the scope of delivery |

| 32 - | Brake line |

| 33 - | 30 Nm + 30° |

| t | replace after each removal |

| 34 - | Brake caliper |

| t | repairing → Chapter |

|

|