| –

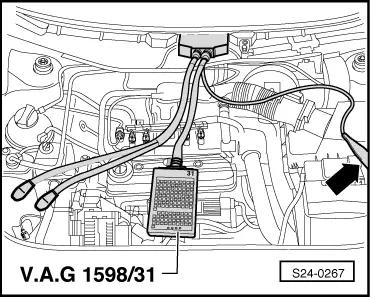

| Connect the test box -V.A.G 1598/31- to the wiring loom on the engine control unit → Chapter. |

| –

| Check the wiring of the knock sensor for short-circuits. |

| If no short-circuit is found: |

| –

| Pull out plug from knock sensor 1 -G61-. |

| –

| Check wiring between test box and knock sensor for interruption according to the current flow diagram. |

|

| Cable resistance: max. 1.5 Ω |

| –

| Measure the resistance between the contacts on the knock sensor. |

| If the lines are not found to be faulty: |

| –

| Slacken knock sensor and then tighten again to 20 Nm. |

|

| During the test drive the following operating conditions must be fulfilled: |

| t

| The coolant temperature should rise beyond 80°C |

| t

| once the temperature is reached, the following operating conditions must be repeated: |

|

| Idling speed

partial load

full load

trailing throttle |

| t

| in case of full load the speed should be increased beyond 3500 rpm-1 |

| –

| Interrogate the fault memory again. |

| If the complaint still exists: |

|

|

|