Octavia Mk1

|

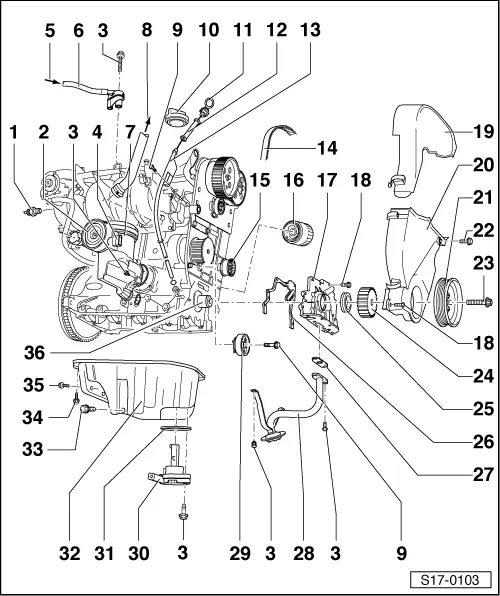

| 1 - | Oil pressure switch 0.03...0.07 MPa (0.3...0.7 bar) -F1-, 25 Nm |

| q | Identification: green |

| q | check → Chapter. |

| q | Replace gasket ring if leaking |

| 2 - | PCV valve |

| q | for engine with engine identification characters BCA |

| 3 - | 10 Nm |

| 4 - | Heating resistor for crankcase ventilation - N79- |

| q | for engine with engine identification characters BCA |

| 5 - | From air filter |

| 6 - | Non-return valve |

| q | from 01.02 |

| 7 - | Oil separator |

| q | only the version for engine with identification characters BCA is illustrated |

| 8 - | To air filter |

| 9 - | 20 Nm |

| 10 - | Cap |

| q | Replace seal if damaged |

| 11 - | Dipstick |

| q | oil level must not exceed max-marking! |

| 12 - | Filler funnel |

| q | Remove for extracting oil |

| 13 - | Guide tube |

| 14 - | Coupling drive-toothed belt |

| q | removing and installing, tensioning → Chapter. |

| q | check for wear |

| q | do not kink |

| 15 - | Guide pulley |

| 16 - | Oil filter |

| q | tighten by hand |

| q | pay attention to installation instructions on oil filter |

| 17 - | Oil pump |

| q | when fitting pay attention to the driver on the crankshaft → Anchor |

| q | must be positioned on dowel sleeves |

| q | removing and installing → Chapter |

| 18 - | 12 Nm |

| 19 - | Top toothed belt guard |

| 20 - | Bottom toothed belt guard |

| 21 - | Belt pulley |

| q | when assembling pay attention to correct installation |

| q | Removing and installing ribbed V-belt → Chapter. |

| 22 - | 20 Nm |

| 23 - | 90 Nm + torque a further 1/4 turn (90 °) |

| q | replace |

| q | moisten with oil before inserting |

| q | tightening may occur in successive stages |

| q | the torquing angle can be measured with a commercially available angle measuring plate, e.g. -Hazet 6690- |

| 24 - | Timing belt gear - crankshaft |

| 25 - | Gasket ring |

| q | replace → Chapter. |

| 26 - | Gasket |

| q | replace |

| q | must be positioned on dowel sleeves |

| 27 - | Gasket |

| q | replace |

| 28 - | Suction line |

| q | Clean strainer if dirty |

| 29 - | Timing belt tensioning pulley |

| q | Tension timing belt → Chapter. |

| 30 - | Oil level and oil temperature sender -G266- |

| q | check → Current flow diagrams and Fitting locations |

| 31 - | Gasket |

| q | replace if damaged |

| 32 - | Oil pan |

| q | removing and installing → Chapter |

| q | clean sealing surface before installing |

| q | install with silicone sealant -D 176 404 A2- |

| 33 - | Oil drain plug, 30 Nm |

| 34 - | 13 Nm |

| q | slacken and tighten only the bolts at the flywheel side with socket wrench SW5, e. g. -3249- |

| 35 - | 45 Nm |

| 36 - | Driver |

| q | coat with oil before installing the oil pump |