| –

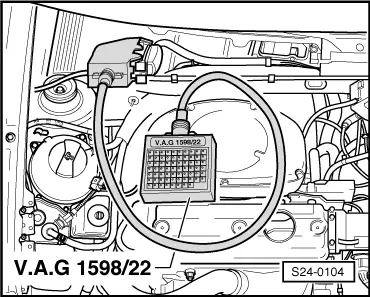

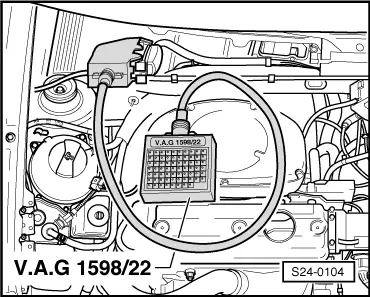

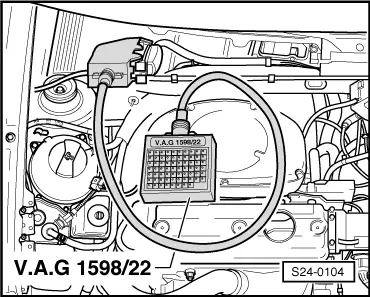

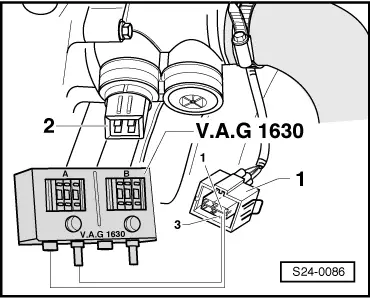

| Connect test box -V.A.G 1598/22 - at wiring loom to the 1AV control unit. |

| –

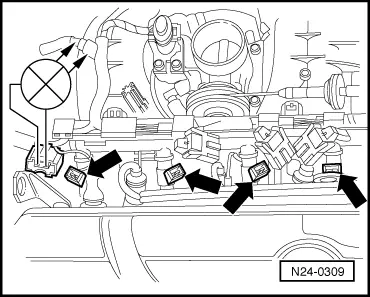

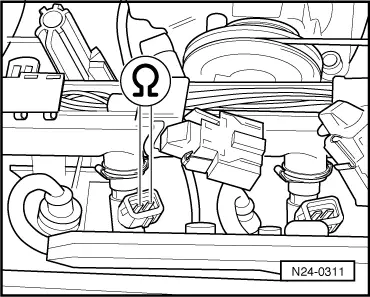

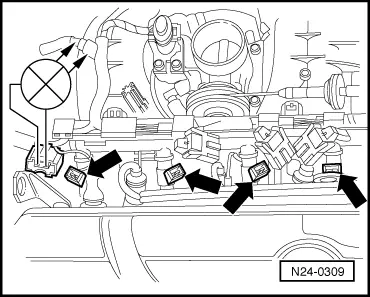

| Check wiring between the test box and the plugs from the injection valves for open circuit according to the current flow diagram. |

|

| Plug on cylinder 1, contact 2+bush 3 |

|

| Plug on cylinder 2, contact 2+bush 80 |

|

| Plug on cylinder 3, contact 2+bush 58 |

|

| Plug on cylinder 4, contact 2+bush 65 |

|

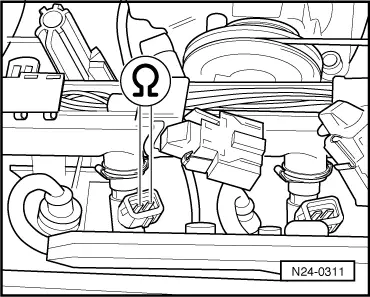

| Cable resistance: max. 1.5 Ω |

| –

| Also check the wires for short-circuits. |

| –

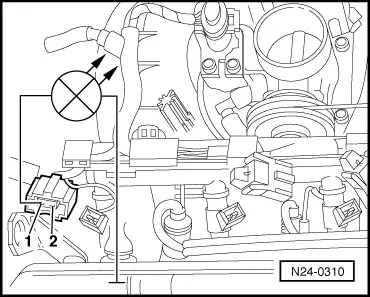

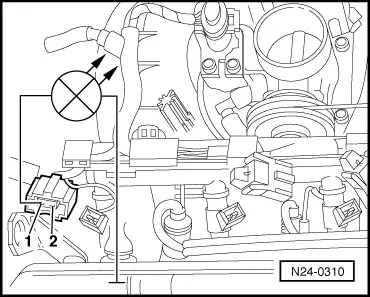

| Check wiring between the contacts 1 of the plugs for the injection valves for open circuit. |

|

| Cable resistance: max. 1.5 Ω |

| –

| Also check the wires for short-circuits. |

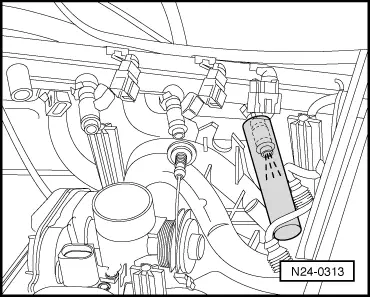

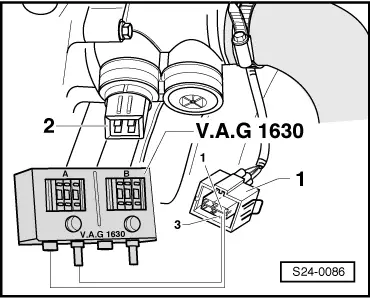

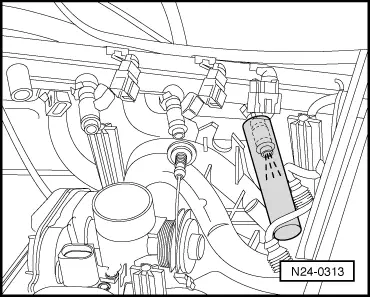

| Testing resistances of the injection valves |

|

|

|

Note

Note

Note

Note