| –

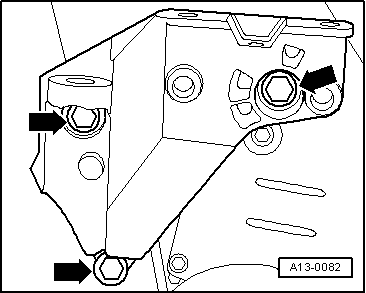

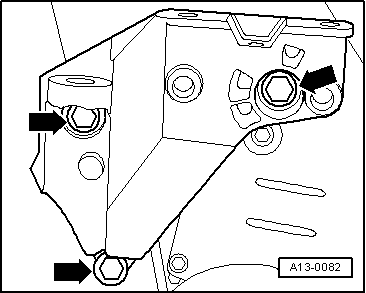

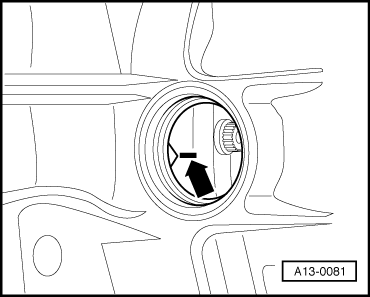

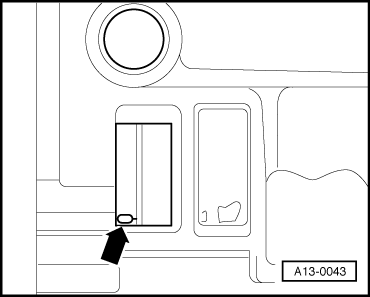

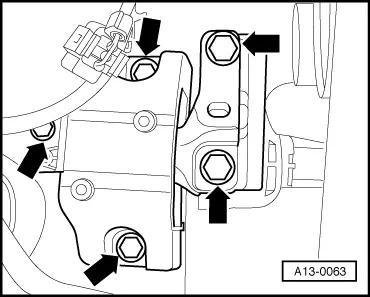

| Unbolt engine support from engine -arrows-. |

Note | t

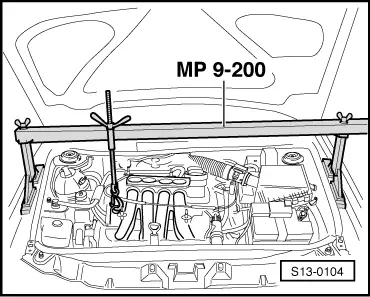

| To slacken the front bolt of the engine support, raise engine slightly with spindle of supporting device -MP 9-200-. |

| t

| To take off engine support, raise or lower engine, respectively with the supporting device -MP 9-200-. |

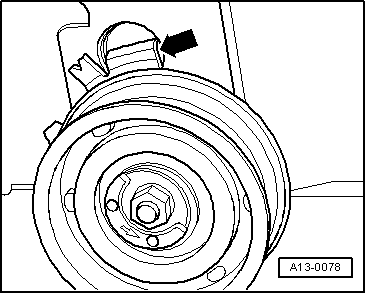

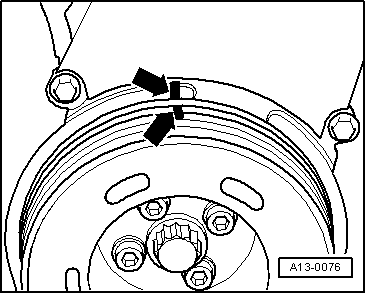

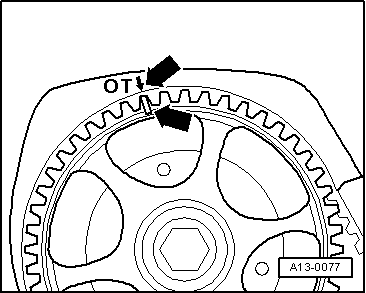

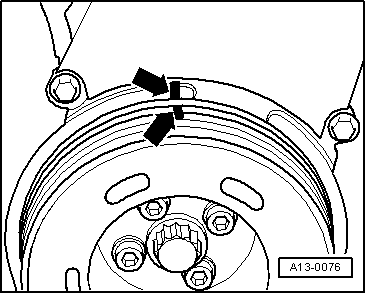

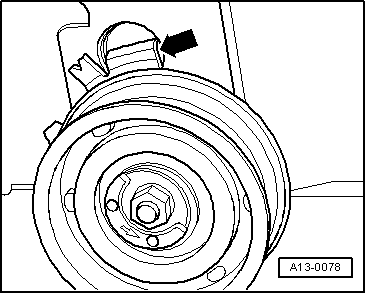

| Installing toothed belt, tensioning (setting timing) |

Note | t

| Also when carrying out repairs which necessitate taking the toothed belt only off the camshaft sprocket, it is then necessary to carry out the installation of the toothed belt as follows. |

| t

| When rotating the camshaft, the crankshaft must not be positioned at TDC. Risk of damaging valves and piston crowns. |

| l

| The pistons must not be positioned at top dead centre. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note