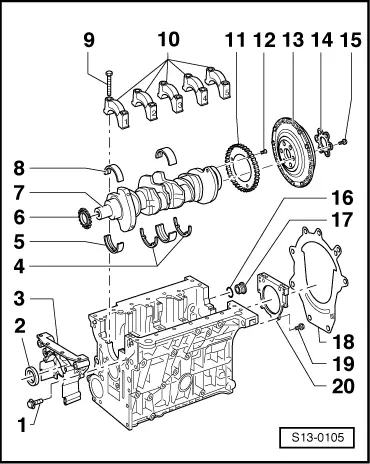

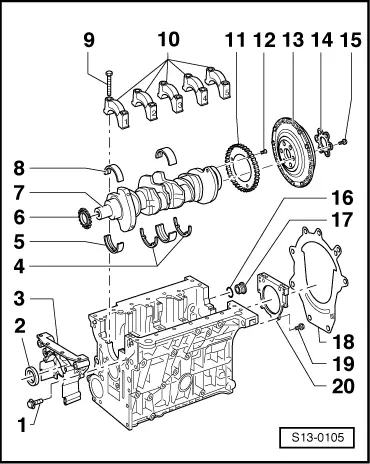

| Removing and installing crankshaft |

Note | t

| The engine should be attached to the engine repair stand with engine holder -MP 1-202- for carrying out removal and installation work. |

| –

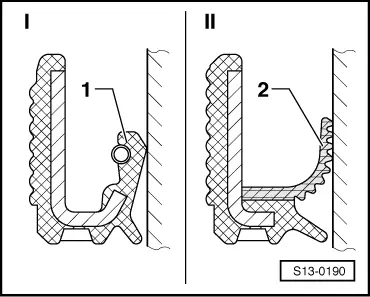

| pay attention to different version → Fig. |

| –

| pay attention to different version |

| –

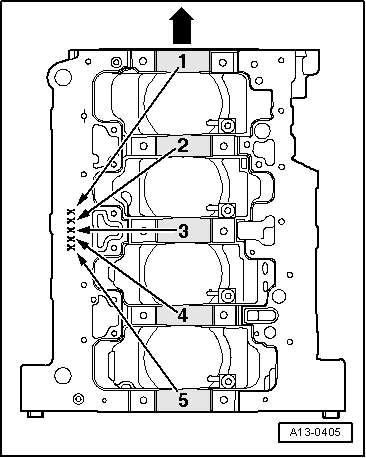

| in bearing 3, for cylinder block or bearing cap |

| –

| lubricating grooves point outwards |

| –

| Identification for ordering replacement parts → Fig. |

| –

| for cylinder block with lubricating groove |

| –

| do not mix up used bearing shells (mark) |

| –

| Axial play when new: 0.07...0.21 mm |

| –

| Crankshaft bearing journal: Ø 54.00 mm |

| –

| Conrod bearing journal Ø 47.80 mm |

| –

| Identification for ordering replacement parts → Fig. |

| –

| for bearing cap without lubricating groove |

| –

| do not mix up used bearing shells (mark) |

| 9 - | 40 Nm + torque a further 1/4 turn (90°) |

| –

| Bearing cover 1; on the belt pulley side |

| –

| Fitting position: retaining lugs of the bearing shells of the cylinder block/bearing cap must be on top of one another |

| –

| for engine speed sender -G28 - |

| –

| assembly only possible in one position -holes offset- |

| –

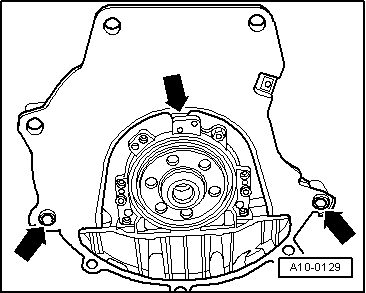

| Removing and installing sensor rotor → Fig. |

| 12 - | 10 Nm + torque a further 1/4 turn (90°) |

| 13 - | Pressure plate/driver disc |

| –

| Removing and installing pressure plate → Chapter |

| –

| removing and installing drive plate → Chapter |

| 15 - | 60 Nm + torque a further 1/4 turn (90°) |

| –

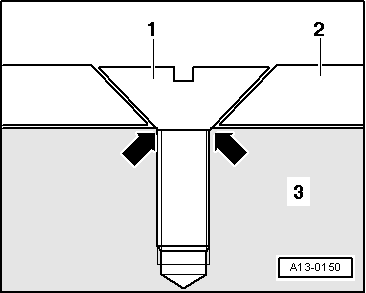

| inserted on sealing flange → Fig. |

| –

| must be positioned on dowel sleeves |

| –

| do not damage/bend during assembly work |

| 20 - | Rear sealing flange with gasket ring |

| –

| must be replaced completely |

| –

| must be positioned on dowel sleeves |

| –

| clean sealing surface before installing |

| –

| the sealing flange with PTFE gasket ring is supplied as a spare part |

| –

| install gasket ring dry, the crankshaft stub must be free of grease |

| –

| fit new sealing flange with guide bushing (do not pull guide bushing out of gasket ring before fitting) |

|

|

|

Note

Note

Note

Note Note

Note