Octavia Mk1

Note

Note

|

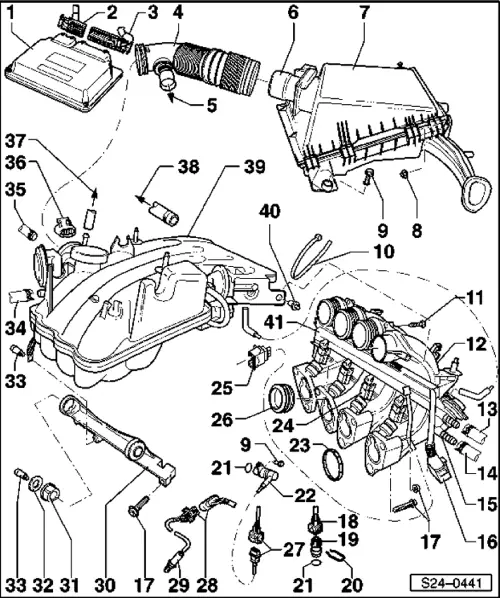

| 1 - | Control unit for Simos 2 -J361 -* |

| q | Fitting location: in plenum chamber |

| q | Checking voltage supply → Chapter |

| q | replace → Chapter |

| 2 - | Connector, 28 pin |

| q | Insert or remove plug when the ignition is switched off |

| q | unlock to remove |

| 3 - | Connector, 52 pin |

| q | Insert or remove plug when the ignition is switched off |

| q | unlock to remove |

| 4 - | Air intake hose |

| 5 - | To oil filler inlet |

| 6 - | Air mass meter -G70-* with intake air temperature sender - G42-* |

| q | up to model year 1997, the intake air temperature sender -G42- is a separate component part |

| q | Testing the air mass meter → Chapter |

| q | Test intake air temperature sender → Chapter |

| 7 - | Air filter |

| q | disassembling and assembling → Chapter |

| 8 - | 6 Nm |

| 9 - | 10 Nm |

| 10 - | Cable strap |

| q | for cable rail Pos. 41 |

| 11 - | 3 Nm |

| 12 - | Bottom part of intake manifold |

| 13 - | Feed line |

| q | secure with spring strap clamps |

| q | from fuel filter: → 1.6 ltr./74 Engine, Mechanics → Rep. Gr.20 |

| 14 - | Return-flow line |

| q | secure with spring strap clamps |

| q | to fuel delivery unit in fuel tank |

| 15 - | Fuel distributor |

| q | disassembling and assembling → Chapter |

| 16 - | Connector |

| q | 3-pin |

| q | for hall sender -G40- |

| 17 - | 15 Nm |

| 18 - | Connector |

| q | 4-pin |

| q | for coolant temperature sender - G62- |

| q | Contacts 1 and 3 gilded |

| 19 - | Coolant temperature sender -G62-* |

| q | blue |

| q | for engine control unit |

| q | with coolant temperature gauge sensor -G2- |

| q | check → Chapter |

| q | before removing, reduce pressure in cooling system if necessary |

| 20 - | Split pin |

| q | check tightness |

| 21 - | O-ring |

| q | replace if damaged |

| 22 - | Engine speed sender -G28-* |

| q | check → Chapter |

| 23 - | Gasket ring |

| q | replace |

| 24 - | Connector |

| q | black, 2 pin |

| q | for injection valves (-N30-...N33) |

| 25 - | Connector |

| q | black, 2 pin |

| q | for variable intake manifold changeover valve -N156- |

| 26 - | Gasket ring |

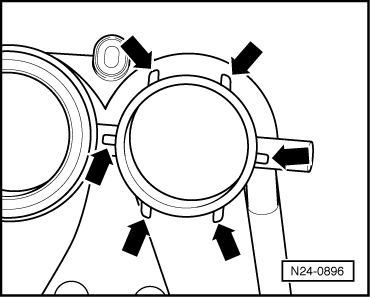

| if no stops are present for correct gasket ring position at the bottom part of the intake manifold: |

| q | Stick gasket ring with glue -D 000 801- and hardener -D 000 802- to the bottom part of the intake manifold. |

| q | Fitting position: → Fig. |

| 27 - | 3-pin connector |

| q | grey |

| q | for engine speed sender |

| q | Fitting location → Chapter |

| 28 - | 4-pin connector |

| q | black |

| q | for lambda probe and heating for lambda probe |

| q | Contacts 3 and 4 gilded |

| q | Fitting location → Chapter |

| 29 - | Lambda probe -G39-* 50 Nm |

| q | grease the thread with “G 052 112 A3”; “G 052 112 A3” must not get into the slots of the probe body |

| q | Checking lambda control → Chapter |

| q | Voltage supply of the heating for lambda probe via fuel pump relay -J17- |

| q | Check heating for lambda probe → Chapter |

| q | Fitting location → Chapter |

| 30 - | Support |

| q | between intake manifold and cylinder head |

| 31 - | Rubber bush |

| 32 - | Washer |

| 33 - | 8 Nm |

| 34 - | to heat exchanger |

| 35 - | from the expansion reservoir |

| 36 - | Connector |

| q | 8-pin |

| q | contacts gold-plated |

| q | for throttle valve control unit -J338- |

| 37 - | to activated charcoal filter system solenoid valve 1 -N80-** |

| q | Activated charcoal filter system: → 1.6 ltr./74 kW Engine, Mechanics → Rep. Gr.20 |

| 38 - | To the brake servo unit |

| 39 - | Top part of intake manifold |

| q | with variable intake manifold changeover |

| q | disassembling and assembling → Chapter |

| 40 - | Body-bound rivet |

| 41 - | Cable rail |