Octavia Mk1

Note

Note

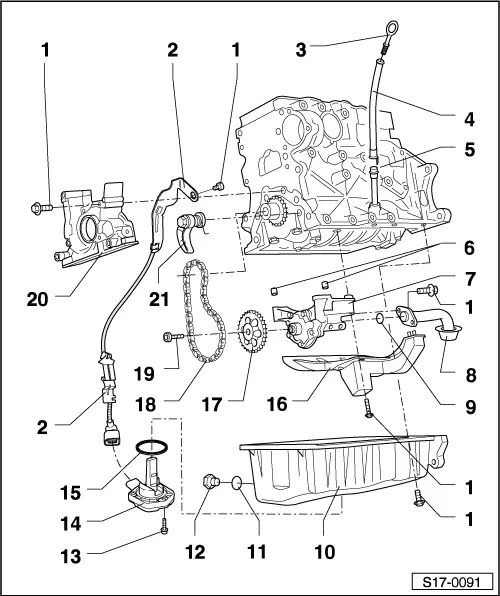

|

| 1 - | 15 Nm |

| 2 - | Support |

| q | for wiring loom from the oil level and oil temperature sender |

| q | different versions: screwed on or clipped in |

| 3 - | Dipstick |

| q | oil level must not exceed max. marking! |

| 4 - | Filler funnel |

| q | Remove for extracting oil |

| 5 - | Guide tube |

| 6 - | Dowel sleeves |

| 7 - | Oil pump |

| q | with pressure relief valve 1.2 MPa (12 bar) |

| q | before installing, inspect whether the two dowel sleeves → Item for centering oil pump/cylinder block are present |

| q | If there is any scoring on contact surfaces and gears, replace |

| 8 - | Suction line |

| q | Clean strainer if dirty |

| 9 - | O-ring |

| q | replace |

| 10 - | Oil pan |

| q | clean sealing surface before installing |

| q | fit with silicone sealant -D 176 404 A2 - → Chapter 17-2 |

| 11 - | Gasket ring |

| q | replace |

| 12 - | Oil drain plug, 30 Nm |

| q | Cut open gasket ring if leaking and replace |

| 13 - | 10 Nm |

| 14 - | Oil level and oil temperature sender -G266- |

| q | Test → Electrical System; Rep. Gr.90 |

| 15 - | Gasket ring |

| q | replace |

| 16 - | Baffle |

| 17 - | Sprocket |

| 18 - | Chain |

| 19 - | 20 Nm |

| 20 - | Front sealing flange |

| q | removing and installing → Chapter 13-3 |

| q | insert with silicone sealant -D 176 404 A2 - → Chapter 13-3 |

| q | replace seal for crankshaft at belt pulley side → Chap. 13-3 |

| 21 - | Chain tensioner with tensioning rail, 15 Nm |

| q | When installing, pretension spring and attach |