| Inspecting the injection rate, tightness and jet formation of the injectors |

| Special tools, test equipment as well as aids required |

| t

| Vehicle system tester -V.A.G 1552- with cable -V.A.G 1551/3-, 3A, 3B or 3C |

| t

| Measuring tool set, e.g. -V.A.G 1594 A-, B or C |

| t

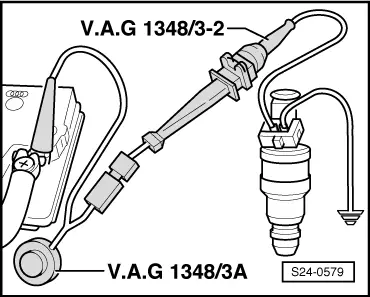

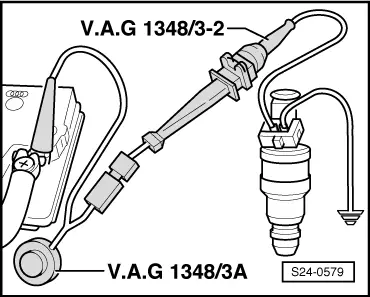

| Remote control -V.A.G 1348/3A- with adapter cable -V.A.G 1348/3-2- |

| t

| Measuring cylinder, e.g. -V.A.G 1602- |

| l

| Fuel temperature 15...20 °C, fuel must according to the valid standards |

| –

| Unplug connectors at all the injectors. |

| –

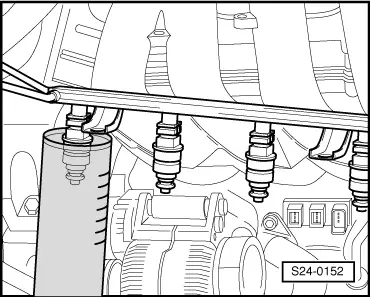

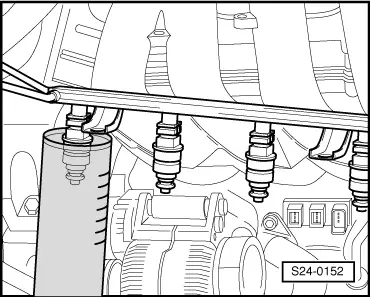

| Remove the complete fuel rail. |

| –

| Detach vacuum hose from fuel pressure regulator. |

| –

| Remove fuel rail together with injectors from intake manifold and support. |

| –

| Connect vehicle system tester -V.A.G 1552-. Switch ignition on and select address word 01 “Engine electronics” → Chapter. |

| –

| Initiate final control diagnosis and drive injector cyl. 1 activate, the fuel pump must run. |

Note | This sequence is intended to ensure that the fuel pump runs when the engine is switched off. The idling speed limit switch must be in closed position as otherwise the selected injector will spray five times. |

| –

| Test the tightness of the injectors (visual inspection). With the fuel pump running per valve only 1...2 drops of fuel may escape per minute. |

| –

| If the fuel loss is greater adjust the fuel pump (end final control diagnosis) and replace defective injector. |

Note | Replace seals at the same time. |

| –

| If necessary repeat final control diagnosis. |

Note | The final control diagnosis can only be initiated again once the ignition has been briefly switched off. |

Note | When testing the injection rate also check the jet formation. The jet must be the same for all injection valves. |

|

|

|

Note

Note Note

Note Note

Note Note

Note

Note

Note Note

Note Note

Note Note

Note