| Removing and installing, tightening the timing belt |

Note | Before removing the timing belt, mark direction of running. Reversing the rotation direction of an already used belt may destroy it. |

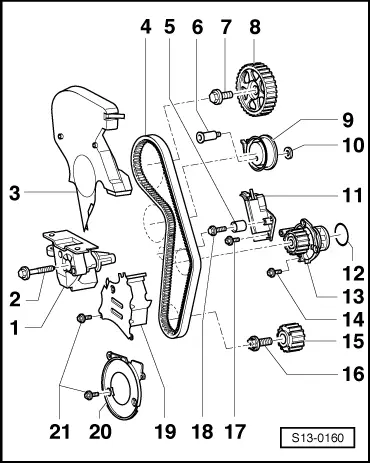

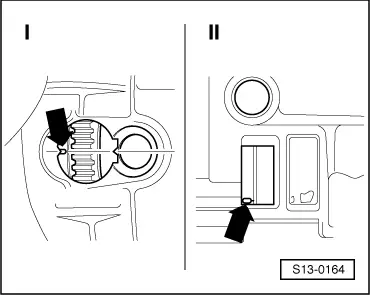

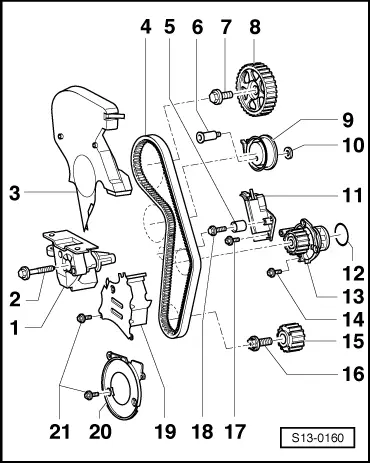

| 3 - | Top toothed belt guard |

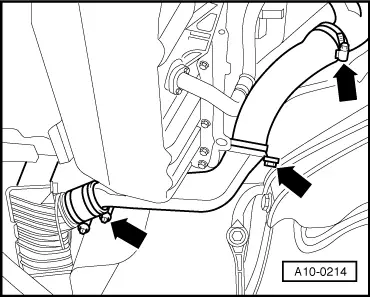

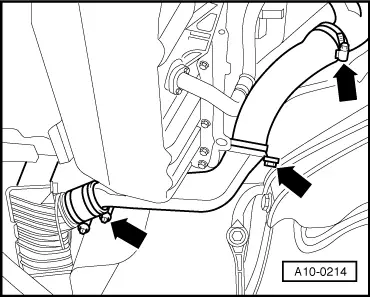

| –

| to remove, if necessary unscrew bracket for coolant return-flow line to exhaust turbocharger |

| –

| before removing mark running direction |

| –

| to release and tighten use the counterholder -MP 1-216- |

| –

| for removing and installing, remove toothed belt → Anchor |

| –

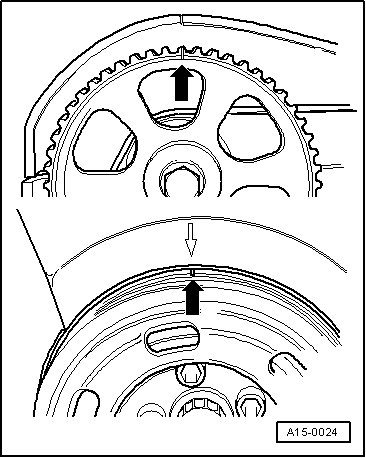

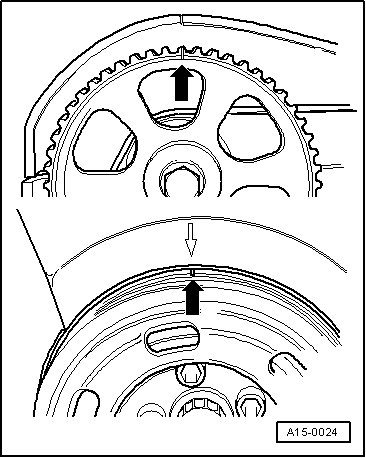

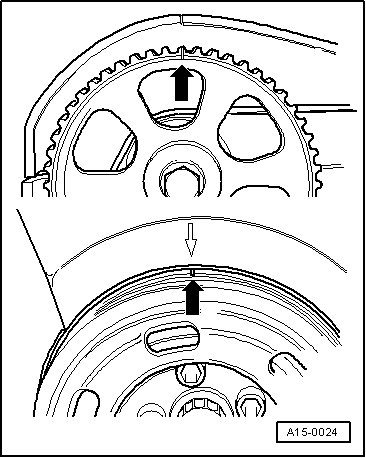

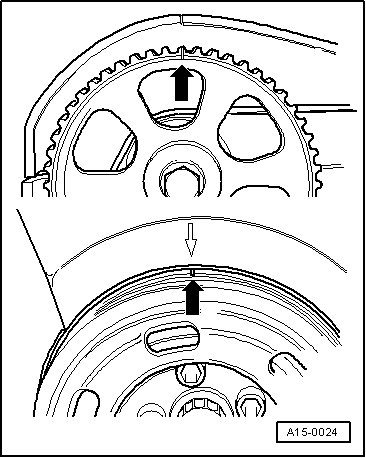

| check fitting position: the small stay on the camshaft sprocket points outwards and the TDC marking on the cylinder 1 is visible |

| 11 - | Tensioning device for timing belt |

| –

| replace, moisten with coolant when installing |

| 15 - | Timing belt gear - crankshaft |

| –

| there must not be any oil present on contact surface between timing belt sprocket and the crankshaft |

| –

| can be installed only in one position |

| 16 - | 90 Nm + torque a further 1/4 turn (90°) |

| –

| to release and tighten the counterholder -MP 1-310- or -T30004- use |

| –

| when bolting on counter-holder -MP 1-310-, place 2 washers between timing belt sprocket and counter-holder |

| 19 - | Middle toothed belt guard |

| 20 - | Bottom toothed belt guard |

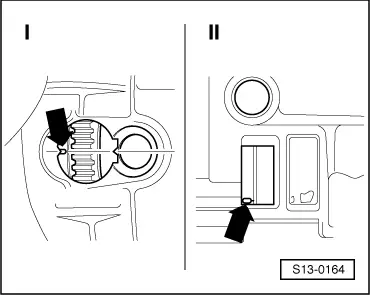

| Special tools and workshop equipment required |

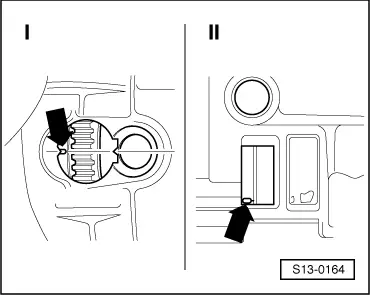

| t

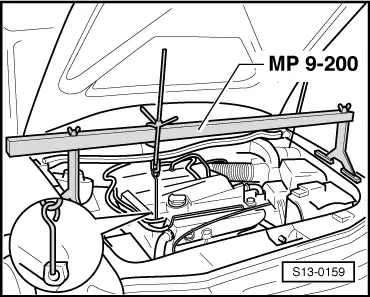

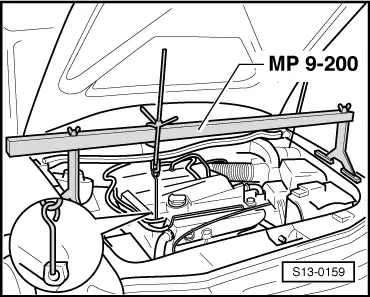

| Supporting device -MP 9-200- |

| t

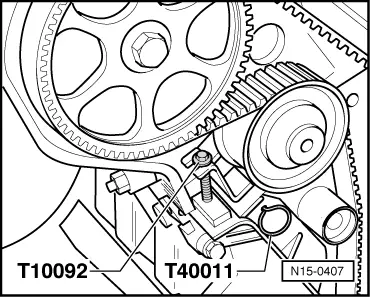

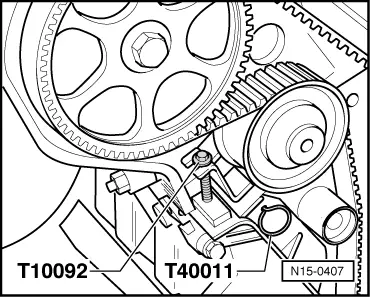

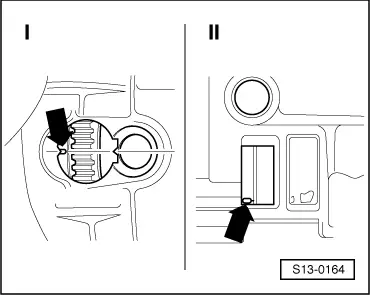

| Locking pin e. g. -T40011- |

| –

| Remove the V-ribbed belt and clamping fixture → Anchor. |

| –

| Disconnect plug at coolant expansion reservoir and at activated charcoal filter system solanoid valve. |

| –

| Unbolt the coolant expansion reservoir and the PAS reservoir, hoses remain connected. |

| –

| Detach the vacuum line from the ACF reservoir and from the throttle valve support. |

| –

| Remove top toothed belt guard. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note