Note | t

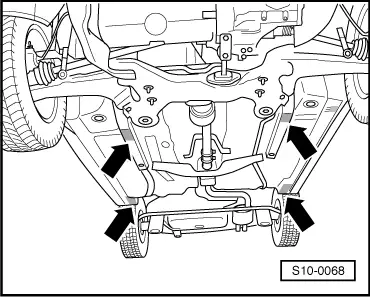

| The engine is removed downwards together with the gearbox. |

| t

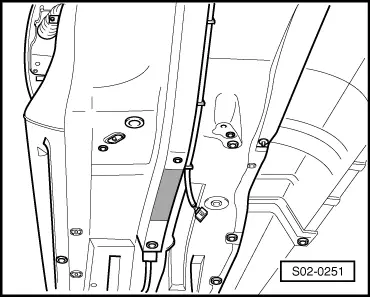

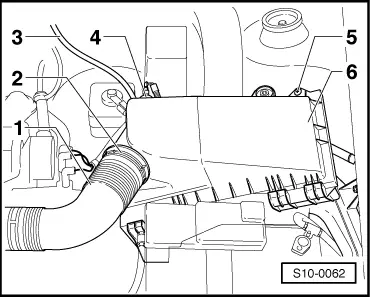

| All cable straps that have been loosened or cut open when the engine was removed must be fitted again in the same location when it is installed again. |

| t

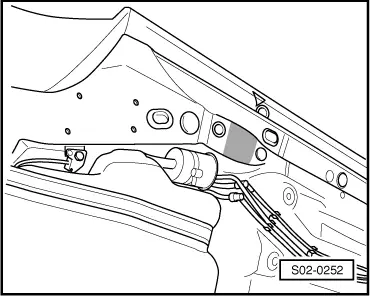

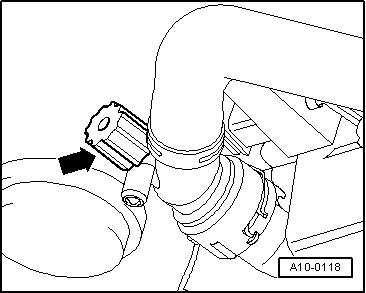

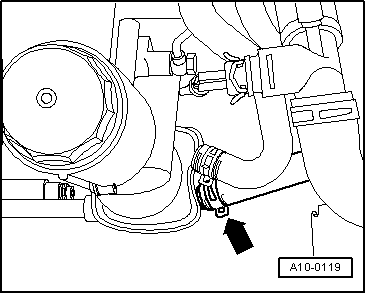

| The hose connections are secured with screw-type clips, spring-type clips or clamp-type clips. |

| t

| Always replace clamp-type clips with screw or spring-type clips. |

| t

| Fuel hoses at the engine must only be secured with spring-type clips. The use of clamp-type or screw-type clips is not allowed. |

| t

| Use pliers for spring strap clips to fit the spring strap clips. |

| t

| Pay attention to correct assignment of the corresponding connectors, if necessary mark. |

| –

| On models fitted with a coded radio set, determine and note the coding. |

| –

| Switch off the ignition and disconnect the battery earth strap. |

|

|

|

Note

Note

Note

Note

Note

Note Note

Note

WARNING

WARNING