Octavia Mk1

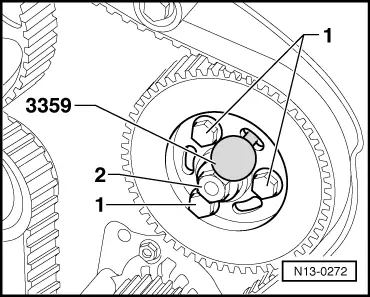

| 1 - | 120 Nm + torque a further (90°) 1/4 turn |

| q | to release and tighten the counterholder -MP 1-310- or counterholder -T30004- use |

| q | always replace |

| q | thread and contact surface must be free of oil and grease. |

| q | tightening to 90° may occur in successive stages |

| 2 - | 40 Nm + torque a further (90°) 1/4 turn |

| q | always replace |

| q | tightening to 90° may occur in successive stages |

| 3 - | 15 Nm |

| 4 - | 23 Nm |

| 5 - | 22 Nm |

| q | for vehicles 03.00 ? |

| 6 - | Bottom toothed belt guard |

| 7 - | 10 Nm |

| 8 - | Middle toothed belt guard |

| 9 - | 45 Nm |

| 10 - | Engine support bracket |

| 11 - | Top toothed belt guard |

| 12 - | Timing belt |

| q | before removing mark running direction |

| q | check for wear |

| q | do not kink |

| q | removing and installing → Anchor |

| 13 - | Guide pulley |

| q | for vehicles 03.00 ? |

| 14 - | 20 Nm + torque a further (90°) 1/4 turn |

| q | replace |

| q | tightening to 90° may occur in successive stages |

| 15 - | 20 Nm |

| 16 - | screw for guide pulley |

| q | 17 Nm for console - → Item; spare part No. 038 903 143 E/F |

| q | 20 Nm for console - → Item; spare part No. 038 903 143 A/B |

| 17 - | 45 Nm |

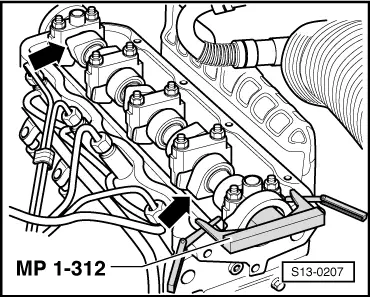

| q | hold camshaft sprocket with counterholder -MP 1-216 - for slackening and tightening |

| 18 - | Camshaft sprocket |

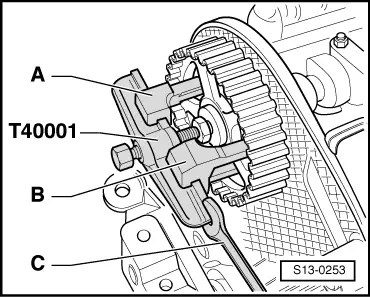

| q | pull off from cone of camshaft with puller -T40001- |

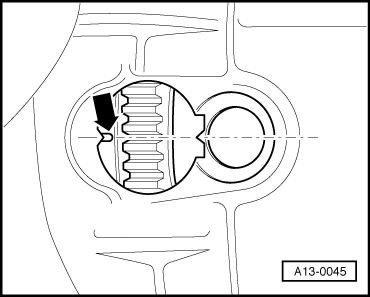

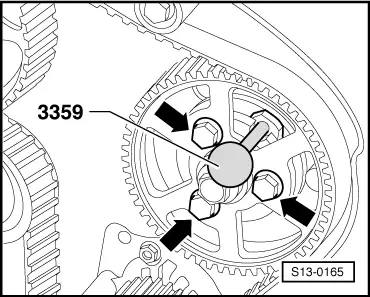

| 19 - | Semi-automatic tensioning pulley |

| q | inspecting semi-automatic timing belt tensioning pulley → Chapter |

| q | Fitting position → Fig. |

| 20 - | Guide pulley |

| 21 - | 30 Nm |

| 22 - | Rear timing belt guard |

| q | insert at the lower edge behind the front sealing flange |

| 23 - | Injection pump gear |

| q | for vehicles 08.97 ? |

| 24 - | Injection pump gear |

| q | for vehicles 07.97 ? |

| 25 - | Coolant pump |

| q | removing and installing → Chapter |

| 26 - | Guide pulley |

| q | to remove, unscrew the coolant pump |

| 27 - | Timing belt gear - crankshaft |

| q | there must not be any oil present on contact surface between timing belt sprocket and the crankshaft |

| q | Fitting position: the flats on the timing belt gear and the crankshaft must correspond |

| 28 - | Bush |

| 29 - | Nut |

| q | insert in bush → Item |

| 30 - | Injection pump |

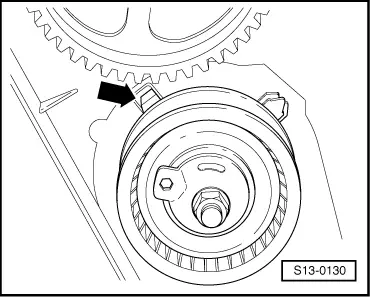

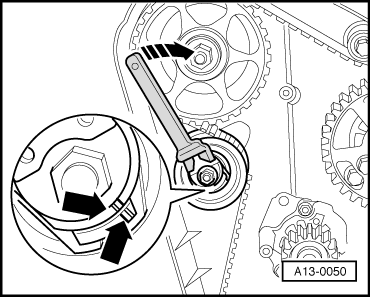

| q | do not unscrew central nut -arrow- |

| q | removing and installing → 1.9 ltr./66 kW (TDI) Engine, Fuel Injection and Glow Plug System → Rep. Gr.23 |

| 31 - | 45 Nm |

| 32 - | Console |

| q | for vehicles without air conditioning |

| q | for injection pump, generator and vane pump |

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

WARNING

WARNING