| –

| Read measured value block, display group 013, engine at idling speed → Chapter. |

| Specified value: -1.50 mg/s... +1.50 mg/s (Milligram per stroke) |

| –

| If one or more nominal values are outside the tolerance, interchange the injection nozzles with each other (except for the nozzle of cylinder 3). |

| –

| If the fault migrates with the nozzle, replace the injection nozzle. |

| –

| If the fault remains on the cylinder, check the compression. |

| –

| If the compression is O.K., replace the relevant pressure valve with gasket ring → Chapter. |

Note | t

| The gasket ring must be removed from the pump with a soft object (plastic, wood) as otherwise the contact surfaces may be scratched. |

| t

| For mileages above 15.000 km replace the pressure valves per set only. |

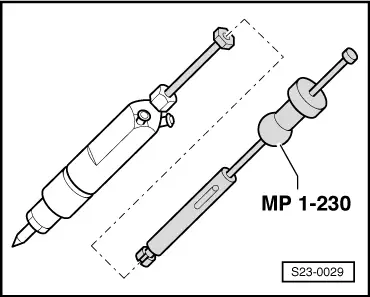

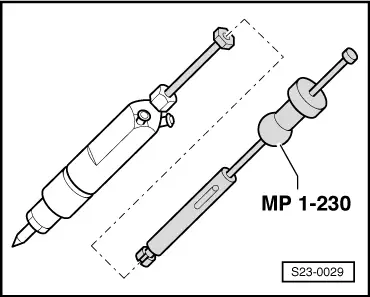

| This engine is fitted with 2 spring injection nozzles. This is why the injection of the fuel quantity occurs in 2 steps. If there is a problem with these injection nozzles they must be replaced, as neither a pressure adjustment nor a repair is possible. |

|

|

Reading measured value block 13 -> | 0.82mg/s -0.12mg/s 0.49mg/s |

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note