Note | t

| Cylinder heads with cracks between the valve seats or between a valve seat ring and the spark plug thread may continue to be used without any reduction in life provided these are slight initial cracks which are not more than 0.3 mm wide, or cracks exist only at the first 4 turns of the spark plug thread. |

| t

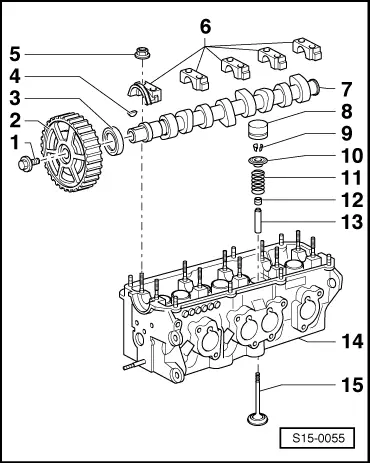

| After installing new bucket tappets, the engine must not be started for about 30 minutes (otherwise place the valves on the pistons). |

| t

| After carrying out work on the valve gear, carefully crank engine at least 2 revolutions to ensure that no valve touches the piston when the engine is started. |

| –

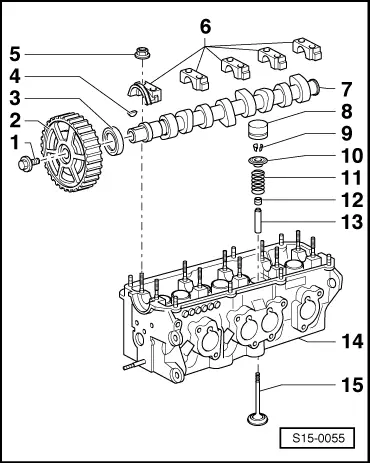

| to release and tighten use the counterholder -T30004- |

| –

| with sensor rotor for the Hall sensor -G40- |

| –

| to remove and install, remove toothed belt → Chapter fix installation position by woodruff key -pos. 4- |

| –

| Lightly coat head contact surface 1 with sealant - AMV 174 004 01 - |

| –

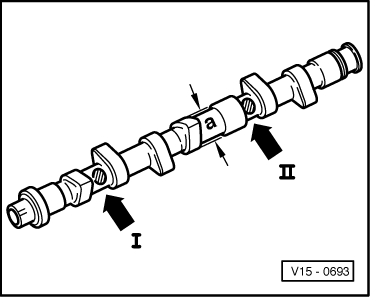

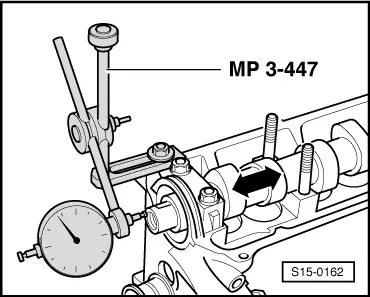

| Inspecting axial play → Fig. |

| –

| Identification, timing → Fig. |

| –

| with hydraulic valve clearance compensation |

| –

| lay aside with contact surface facing down |

| –

| before installing check axial play of the camshaft → Fig. |

| 10 - | Valve spring retainer |

| –

| removing and installing |

| –

| with cylinder head removed: with -MP 1-211- and -MP 1-213- with valve supporting plate -MP 1-218 - |

| –

| Repair of the guide with a collar |

| –

| do not rework, only grinding in is permissible |

|

|

|

Note

Note

Note

Note