| Removing and installing parts of the lubrication system |

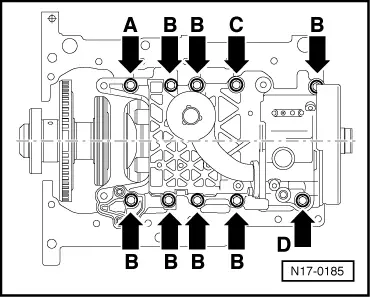

| For engine with identification characters AEG, APK, AQY and AZH |

Note | t

| If considerable quantities of metal swarf or abrasion is found in the engine oil when carrying out engine repairs, carefully clean the oil galleries in order to avoid consequential damage and additionally replace the oil cooler. |

| t

| The engine oil level must never exceed the max. marking - risk of damage to catalytic converter! |

| –

| with pressure relief valve 1.2 MPa (12 bar) |

| –

| Before installing, check whether both dowel sleeves for centering oil pump/cylinder block are present |

| –

| if there is any scoring on contact surfaces and gears, replace |

| –

| Fits onto oil pump shaft in one position only |

| –

| coat with silicone sealant -D 176 404 A2- → Chapter |

| –

| replace the gasket ring for the crankshaft → Chapter |

| 7 - | Chain tensioner, 15 Nm |

| –

| When installing, pretension spring and attach |

| –

| oil level must not exceed max-marking! |

| –

| Remove for extracting oil |

| 12 - | Oil injection nozzle |

| 13 - | Pressure relief valve, 27 Nm |

| –

| opens at 0.25…0.32 MPa (2.5…3.2 bar) overpressure |

| –

| replace without sealant |

| –

| Clean strainer if dirty |

| –

| install with silicone sealant -D 176 404 A2- → Anchor |

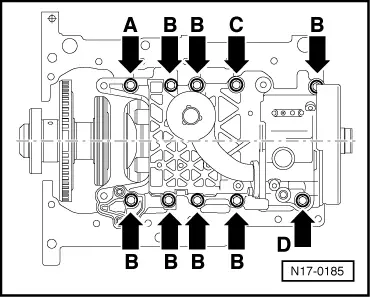

| For engine with engine code AZJ |

Note | t

| If considerable quantities of metal swarf or abrasion is found in the engine oil when carrying out engine repairs, carefully clean the oil galleries in order to avoid consequential damage and additionally replace the oil cooler. |

| t

| The engine oil level must never exceed the max. marking - risk of damage to catalytic converter! |

| –

| Wiring for oil level and oil temperature sender |

| –

| oil level must not exceed max-marking! |

| –

| Remove for extracting oil |

| 8 - | Pressure relief valve, 27 Nm |

| –

| replace without sealant |

| 9 - | Gearbox with balancing shafts and oil pump |

| –

| with pressure relief valve 1.2 MPa (12 bar) |

| 10 - | 15 Nm + torque a further 90° (1/4 turn) |

| –

| pay attention to the different screw lengths |

| –

| install with silicone sealant -D 176 404 A2- → Anchor |

| 17 - | Oil level and oil temperature sender -G266- |

| 19 - | 20 Nm + torque a further 90° (1/4 turn) |

| –

| coat with silicone sealant -D 176 404 A2- → Chapter |

| –

| replace the gasket ring for the crankshaft → Chapter |

|

|

|

Note

Note Note

Note

Note

Note Note

Note