| Removing and installing, tightening the timing belt |

Note | Before removing the timing belt, mark direction of running. Reversing the rotation direction of an already used belt may destroy it. |

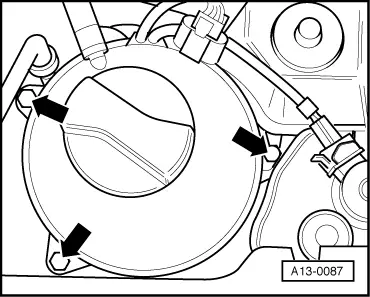

| 1 - | Timing belt guard - bottom part |

| –

| unscrew to remove the belt pulley/vibration damper → Chapter |

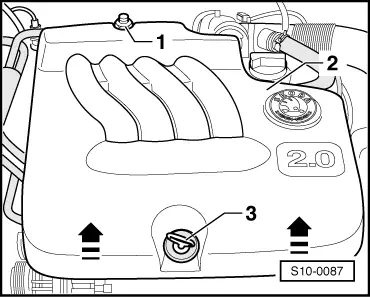

| 2 - | Timing belt guard - middle part |

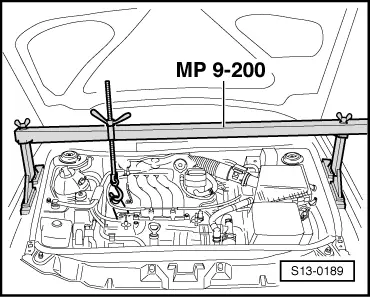

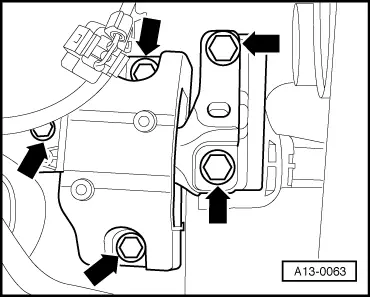

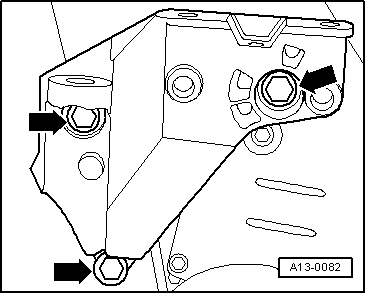

| 4 - | Engine support bracket |

| 6 - | Timing belt guard - top part |

| –

| before removing mark running direction |

| –

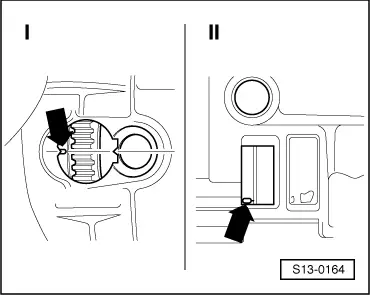

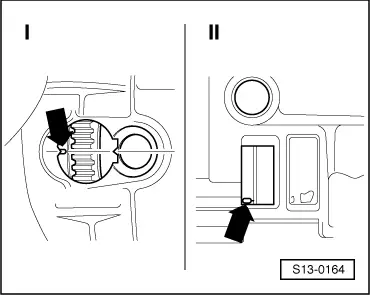

| to release and tighten the counterholder -T30004- and -MP 1-216- use |

| –

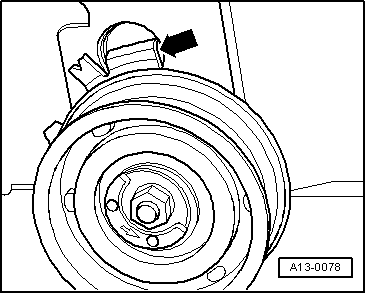

| with sensor rotor for camshaft position sensor -G40 - |

| –

| for removing and installing, remove toothed belt → Anchor |

| –

| Fix installation position by woodruff key pos. 14 |

| 15 - | Camshaft position sensor -G40- |

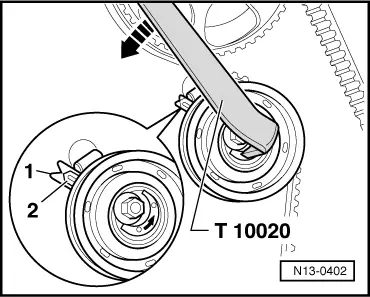

| –

| when bolting on, ensure base plate is centered |

| 17 - | Rear toothed belt guard |

| 19 - | Toothed belt tensioning pulley |

| –

| check semi-automatic tensioning pulley → Chapter |

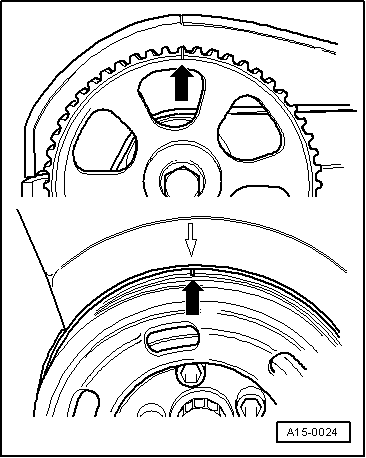

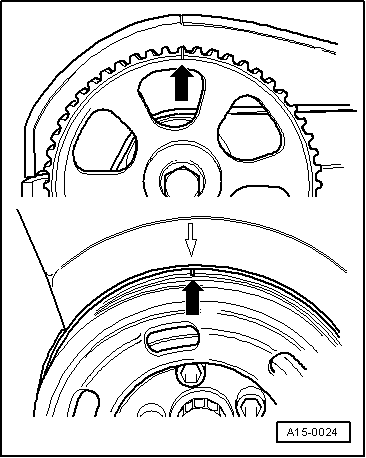

| 22 - | Toothed belt sprocket - crankshaft |

| –

| there must not be any oil present on the contact surface between the toothed belt sprocket and the crankshaft |

| –

| can be installed only in one position |

| 23 - | 90 Nm + torque a further 1/4 turn (90°) |

| –

| Fit bolt in original condition, do not oil or grease |

| –

| to release and tighten the counterholder -T30004- or -MP 1-310- use |

| –

| when bolting on counter-holder -MP 1-310-, place 2 washers between timing belt sprocket and counter-holder |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note