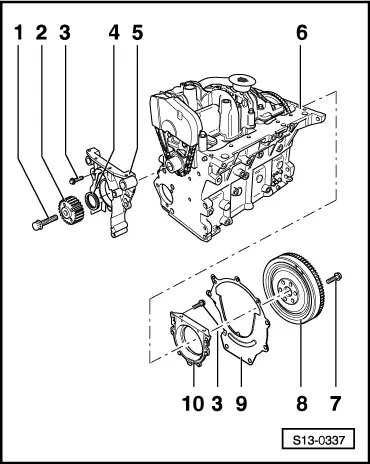

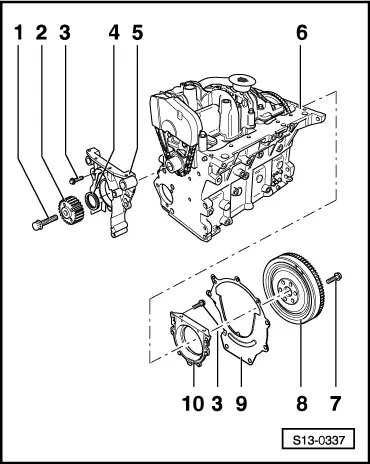

| Removing and installing sealing flange and flywheel |

| For engine with identification characters AEG, APK, AQY and AZH |

Note | t

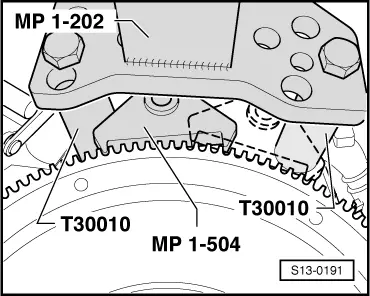

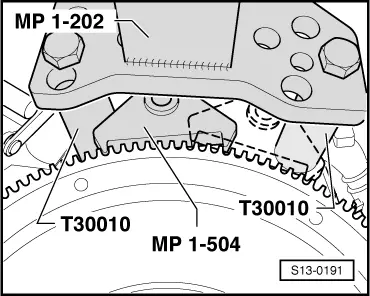

| Secure the engine with engine mount -MP 1-202 - and distance sleeves -T30010- on the assembly stand before performing assembly work. |

| –

| 90 Nm + torque a further 90° (1/4 turn) |

| –

| Fit bolt in original condition, do not oil or grease |

| –

| to release and tighten the counterholder -MP 1-310- or -T30004- use |

| –

| when bolting on counter-holder -MP 1-310-, place 2 washers between timing belt sprocket and counter-holder |

| 2 - | Toothed belt sprocket - crankshaft |

| –

| can be installed only in one position |

| –

| Removing and installing, tightening the timing belt → Chapter |

| –

| pay attention to different version → Fig. |

| –

| must be positioned on dowel sleeves |

| –

| removing and installing crankshaft → Chapter |

| –

| Disassembling and assembling piston and conrod → Chapter |

| 7 - | 60 Nm + torque a further 90° (1/4 turn) |

| –

| tightening may occur in successive stages |

| –

| same tightening torque for drive plate |

| –

| assembly only possible in one position -holes offset- |

| –

| lock flywheel with flywheel lock -MP 1-504 - for removing and installing → Fig. |

| –

| removing and installing drive plate → Chapter |

| –

| must be positioned on dowel sleeves |

| –

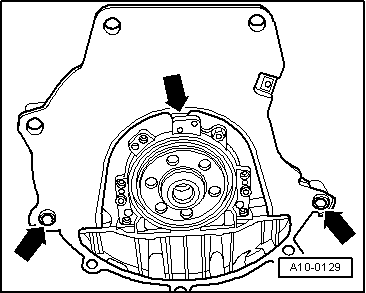

| do not damage/bend during assembly work |

| –

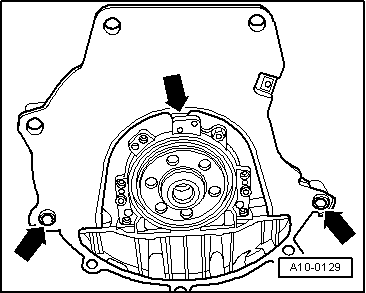

| hang on the sealing flange → Fig. |

| 10 - | Sealing flange with PTFE gasket ring |

| –

| to remove and install, take off oil pan → Chapter |

| –

| must be replaced completely |

| –

| only mount sealing flange with PTFE gasket ring (polytetrafluorethylen) |

| –

| install gasket ring dry, the crankshaft stub must be free of oil |

| –

| install new sealing flange with guide sleeve (do not pull guide sleeve off the seal before installing) |

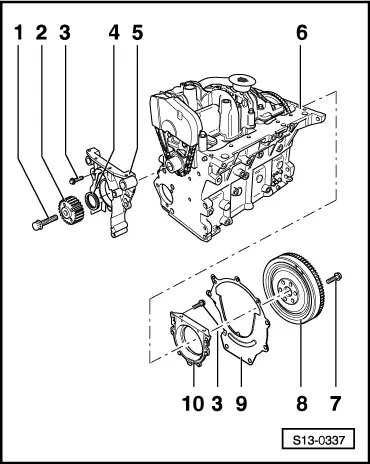

| For engine with engine code AZJ |

Note | t

| Secure the engine with engine mount -MP 1-202 - and distance sleeves -T30010- on the assembly stand before performing assembly work. |

| –

| 90 Nm + torque a further 90° (1/4 turn) |

| –

| Fit bolt in original condition, do not oil or grease |

| –

| to release and tighten the counterholder -MP 1-310- or -T30004- use |

| –

| when bolting on counter-holder -MP 1-310-, place 2 washers between timing belt sprocket and counter-holder |

| 2 - | Toothed belt sprocket - crankshaft |

| –

| can be installed only in one position |

| –

| Removing and installing, tightening the timing belt → Chapter |

| –

| pay attention to different version → Fig. |

| –

| must be positioned on dowel sleeves |

| –

| removing and installing crankshaft → Chapter |

| –

| Disassembling and assembling piston and conrod → Chapter |

| 7 - | 60 Nm + torque a further 90° (1/4 turn) |

| –

| tightening may occur in successive stages |

| –

| same tightening torque for drive plate |

| –

| assembly only possible in one position -holes offset- |

| –

| lock flywheel with flywheel lock -MP 1-504 - for removing and installing → Fig. |

| –

| removing and installing drive plate → Chapter |

| –

| must be positioned on dowel sleeves |

| –

| do not damage/bend during assembly work |

| –

| hang on the sealing flange → Fig. |

| 10 - | Sealing flange with PTFE gasket ring |

| –

| to remove and install, take off oil pan → Chapter |

| –

| must be replaced completely |

| –

| only mount sealing flange with PTFE gasket ring (polytetrafluorethylen) |

| –

| install gasket ring dry, the crankshaft stub must be free of oil |

| –

| install new sealing flange with guide sleeve (do not pull guide sleeve off the seal before installing) |

|

|

|

Note

Note Note

Note

Note

Note Note

Note