| –

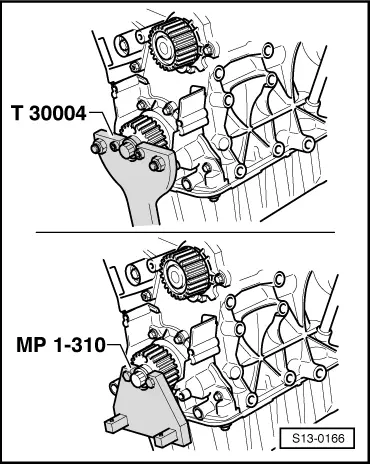

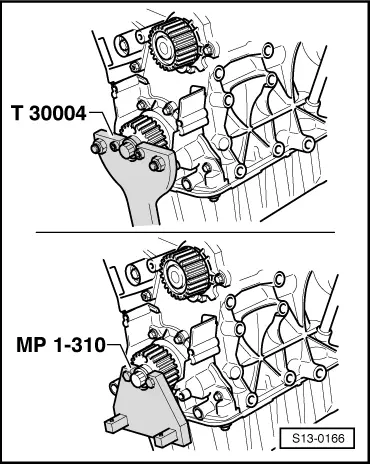

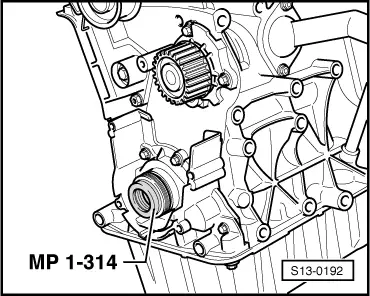

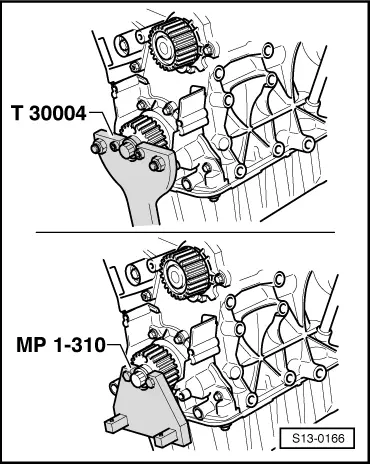

| Remove crankshaft timing belt sprocket. Lock timing belt sprocket with counterholder -T30004- or counterholder -MP 1-310-. |

Note | When screwing on the counterholder place 2 washers between the timing belt gear and the counterholder. |

| –

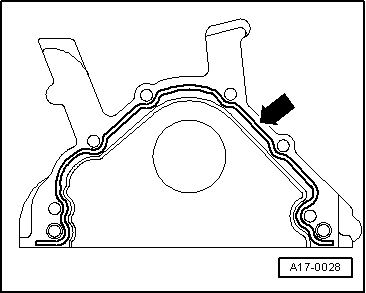

| Unscrew front sealing flange. |

| –

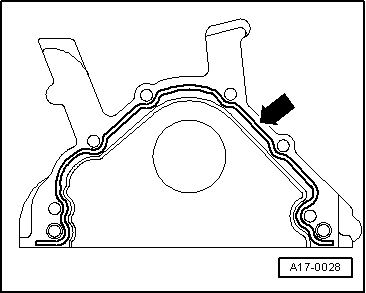

| Remove sealing flange, if necessary release by applying slight blows with a rubber-headed hammer. |

WARNING | Wear protective gloves when working with sealant and grease remover! |

|

| –

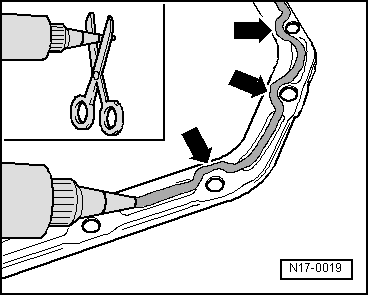

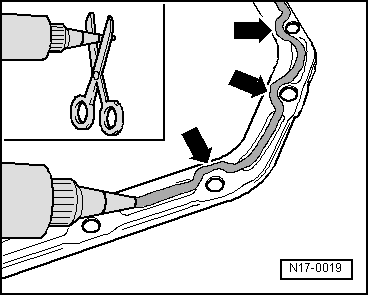

| Remove residual sealant from the sealing surfaces on sealing flange, cylinder block and on the oil pan with chemical sealant remover. |

| –

| Clean sealing surfaces, they must be free of oil and grease. |

Note | t

| Pay attention to the use by date on sealant. |

| t

| The sealing flange must be installed within 5 minutes after applying the silicone sealant. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note

Note

Note