Octavia Mk1

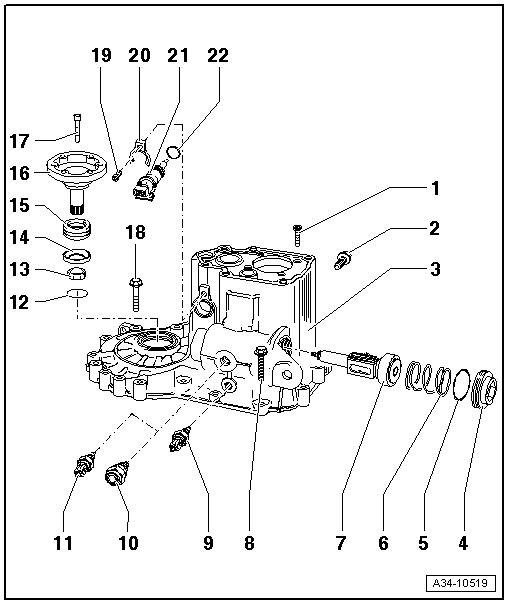

| Summary of components - removing and installing gearbox housing and shift mechanism |

| 1 - | Oval-head countersunk screw, 15 Nm |

| q | M7 x 23 |

| q | 4 pieces |

| q | for tensioning plate/grooved ball bearing to gearbox housing |

| 2 - | 20 Nm |

| q | for shaft/reverse gear |

| 3 - | Gearbox housing |

| q | repairing → Chapter |

| q | as of gearbox manufacturing date 03 08 8 with additional threaded bore for the reversing light switch -F4 - Pos. 9 |

| q | Assembly of a gearbox housing with an additional threaded bore on gearboxes up to gearbox manufacturing date 02 08 8 → Fig. |

| 4 - | Screw cap, 50 Nm |

| 5 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

| 6 - | Pressure spring |

| q | presses gearshift shaft and shift lever into the 3rd and 4th gear gate |

| 7 - | Gearshift shaft |

| q | disassembling and assembling → Chapter |

| 8 - | 25 Nm |

| q | M8 x 35 |

| q | 2 pieces |

| q | screw in below the locking screw Pos. 11 or Pos. 10 |

| 9 - | Reversing light switch -F4-, 23 Nm |

| q | installed as of gearbox manufacturing date 03 08 8 |

| q | coat with sealant -AMV 188 200 03- |

| 10 - | Locking screw, 40 Nm |

| q | for gearshift shaft |

| q | installed as of gearbox manufacturing date 03 08 8 |

| q | coat with sealant -AMV 188 200 03- |

| 11 - | Reversing light switch -F4- and locking screw for gearshift shaft, 23 Nm |

| q | installed up to gearbox manufacturing date 02 08 8 |

| q | as of gearbox manufacturing date 03 08 8, the reversing light switch -F4- Pos. 9 and the locking screw Pos. 10 are two components → Fig. |

| q | coat with sealant -AMV 188 200 03- |

| 12 - | Circlip |

| q | holds the conical ring, stop disc and pressure spring in position when the flange shaft is removed |

| 13 - | Conical ring |

| q | with slots for thrust washer catch |

| q | Fitting position: Cone towards differential gear housing |

| 14 - | Thrust washer |

| q | Fitting position: Collar to pressure spring, leg (if present) to conical ring |

| 15 - | Pressure spring |

| 16 - | Flange shaft left |

| q | removing and installing → Chapter |

| 17 - | Conical screw, 25 Nm |

| 18 - | 25 Nm |

| q | M8 x 52 |

| q | 12 pieces |

| 19 - | 5 Nm |

| q | Fixing screw for speedometer drive Pos. 21 |

| 20 - | Support |

| 21 - | Drive for speedometer |

| 22 - | O-ring |

| q | always replace → Electronic Catalogue of Original Parts |

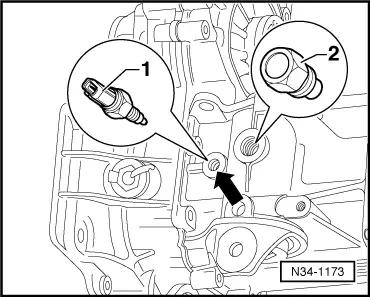

| Reversing light switch -F4--1- | 23 Nm |

| Locking screw -2- | 40 Nm |

|

|

|

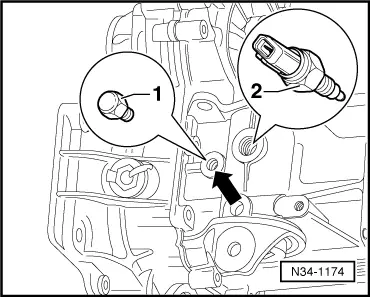

| Reversing light switch -F4--2- | 23 Nm |

| Hexagon screw M12 x 1.5 -1- | 25 Nm |