Octavia Mk1

Note

Note

|

| 1 - | Gearbox housing |

| 2 - | Adjusting washer |

| q | for the differential gear |

| q | Determine thickness → Chapter |

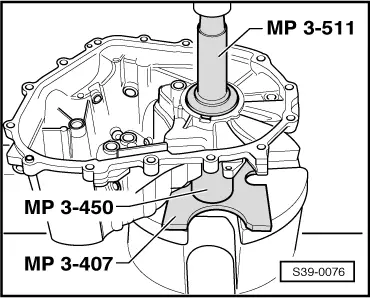

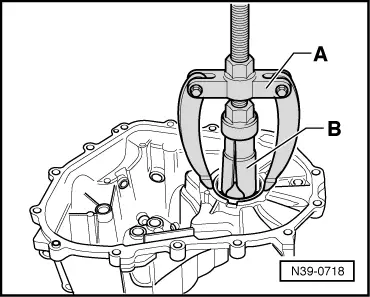

| 3 - | Outer ring/tapered-roller bearing |

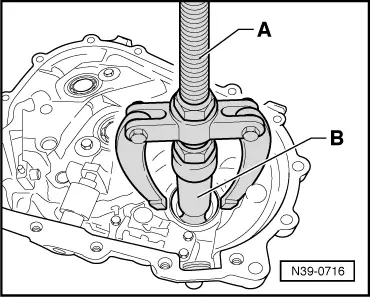

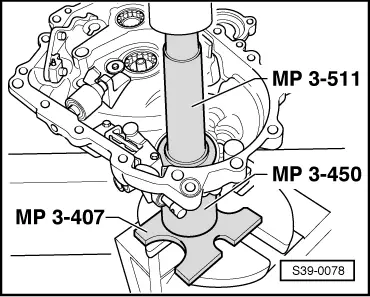

| q | removing → Fig. |

| q | installing → Fig. |

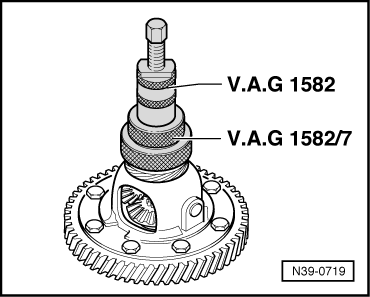

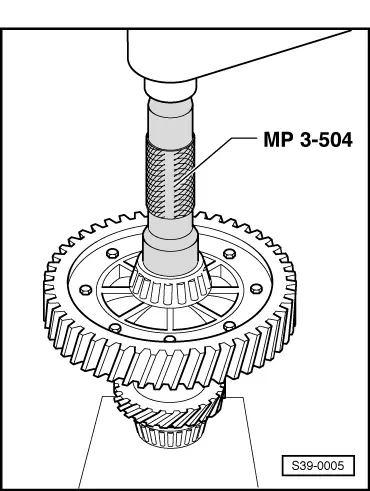

| 4 - | Inner ring/tapered-roller bearing |

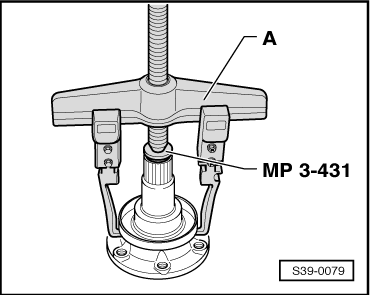

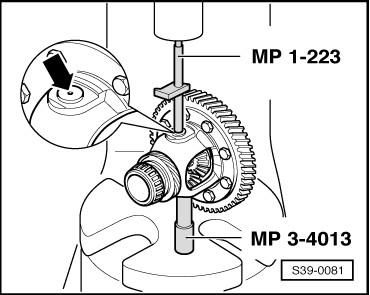

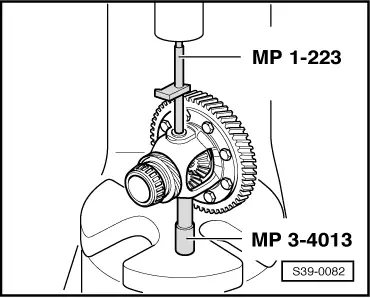

| q | remove → Fig. |

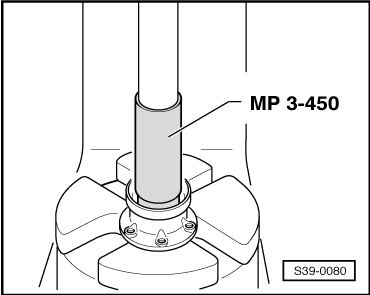

| q | pressing on → Fig. |

| 5 - | Differential gear housing with pinion |

| 6 - | Drive wheel for speedometer |

| q | before pressing on the inner ring place it on the differential gear housing up to the stop |

| 7 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 8 - | Outer ring/tapered-roller bearing |

| q | removing → Fig. |

| q | installing → Fig. |

| 9 - | Clutch housing |

| 10 - | Sealing ring |

| q | replace → Electronic Catalogue of Original Parts, → Chapter |

| 11 - | Flange shaft |

| q | removing and installing → Chapter |

| 12 - | Dust guard |

| q | for flange shaft |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 13 - | Circlip |

| q | always replace → Electronic Catalogue of Original Parts |

| 14 - | Stop disc compound |

| q | insert with gear oil |

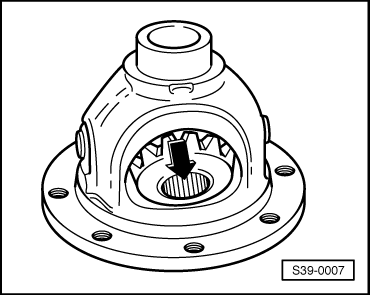

| 15 - | Differential bevel gear large |

| q | installing → Fig. |

| 16 - | Differential bevel gear small |

| q | installing → Fig. |

| 17 - | Circlip |

| q | replace → Electronic Catalogue of Original Parts |

| 18 - | Differential bevel gear shaft |

| q | Shaft has a different diameter, front side with centering hole means a smaller diameter |

| q | pressing out → Fig. |

| q | installing → Fig. |

| 19 - | Pinion for final drive |

| q | is paired with the output shaft, when replacing, replace together → Electronic Catalogue of Original Parts |

| 20 - | Differential gear housing |

| q | screw to pinion for final drive |

| 21 - | Screw, 80 Nm |

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|