| –

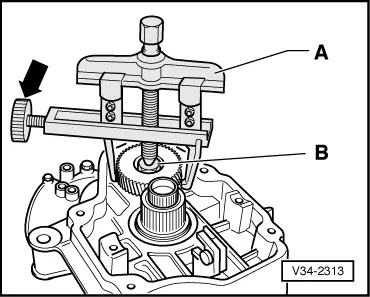

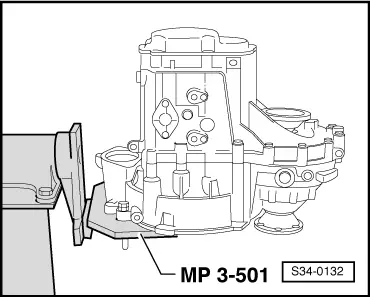

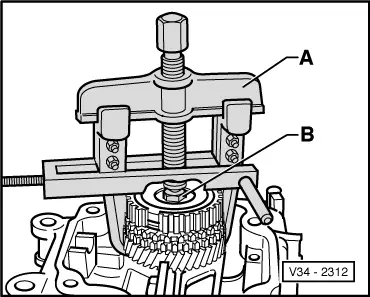

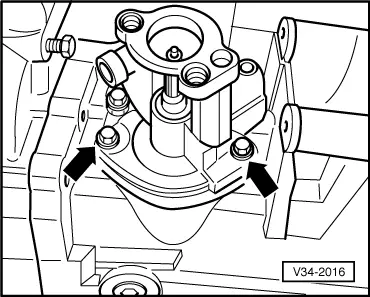

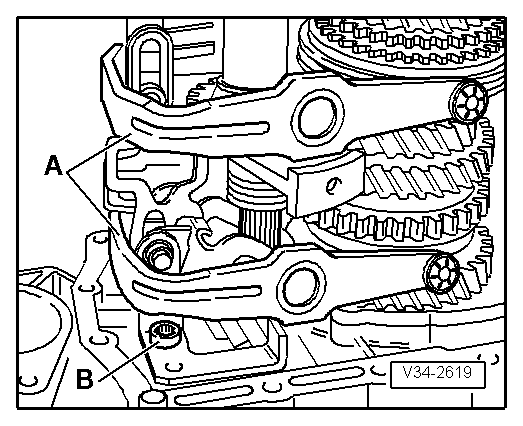

| Remove 5th gear pinion. |

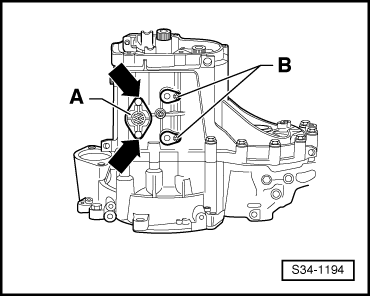

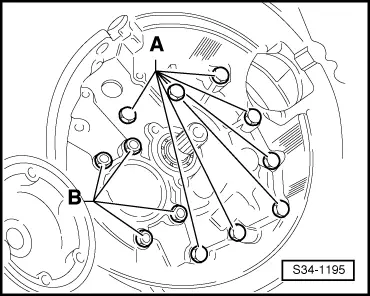

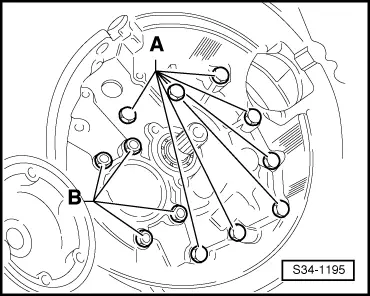

| A - | Two-arm extractor, e.g. -Kukko 20/10-, with hook -Matra V/170- |

| B - | Hexagon screw M10 x 20 mm |

| –

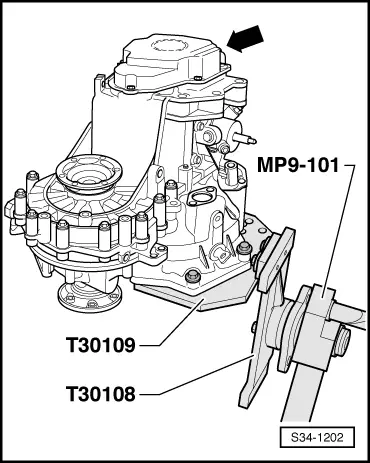

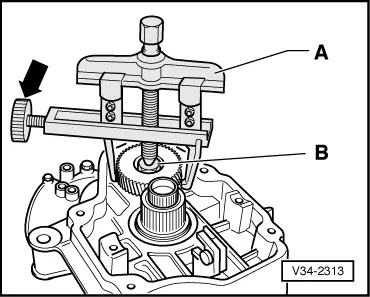

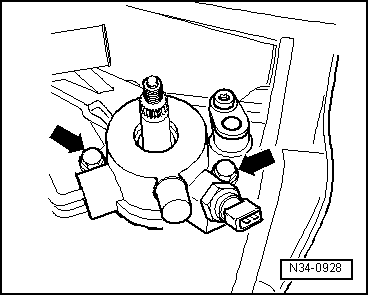

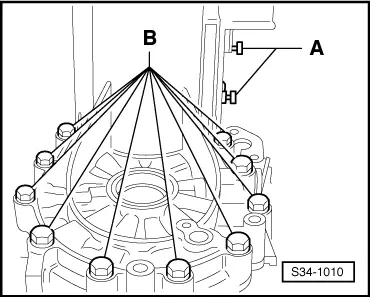

| Set up two-arm extractor and centre by turning the screw -arrow-. |

| –

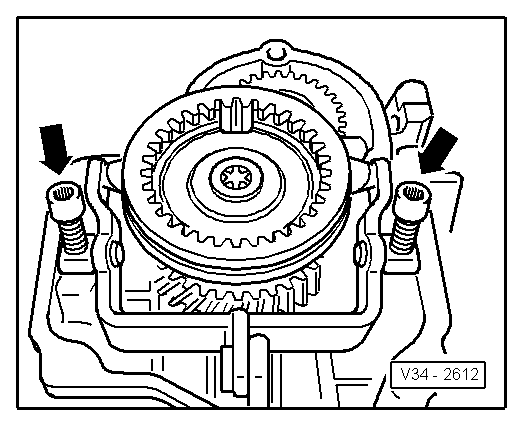

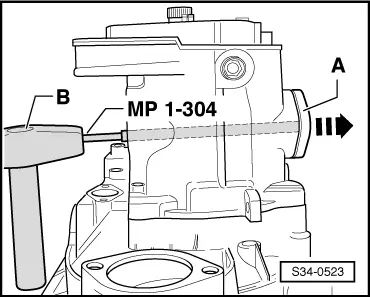

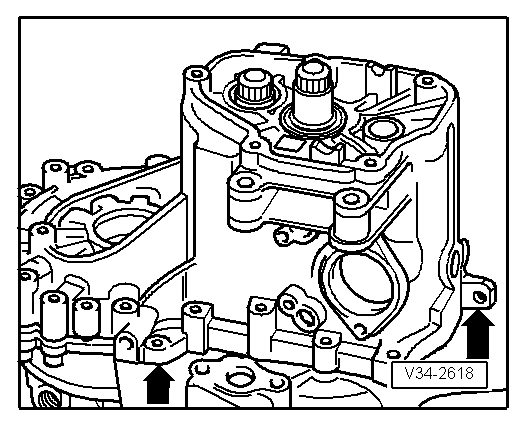

| Remove pinion with two-arm extractor, if necessary first heat with hot-air blower -V.A.G 1416 -. |

Note | t

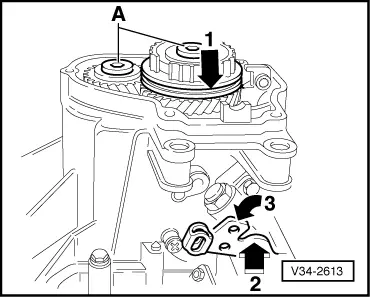

| When pulling off the gear pinion make sure the hooks do not bend outwards, if necessary tighten screw -arrow-. Check 5th gear for damage after removing. |

| t

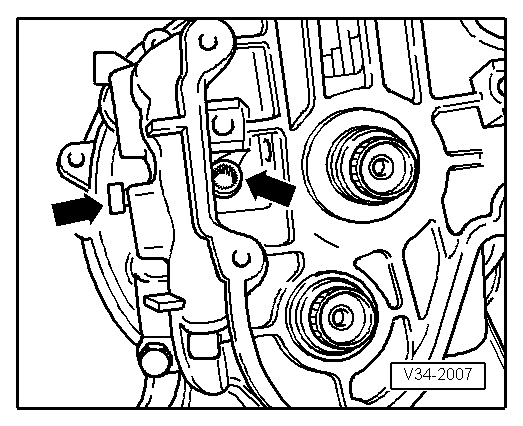

| If the shafts are not replaced, carefully clean the threaded holes using a screw-tap to remove locking agent residues. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note