| –

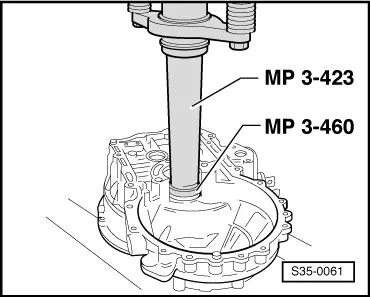

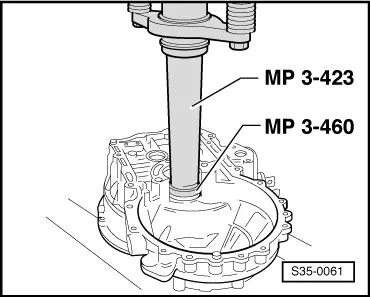

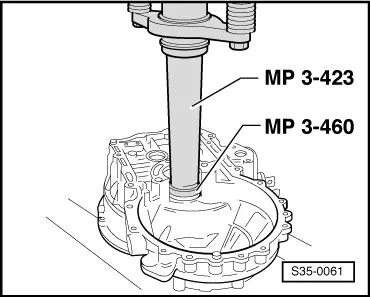

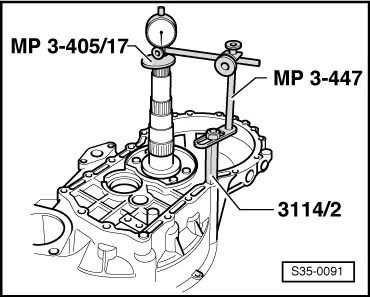

| Press in outer ring/tapered-roller bearing small in the clutch housing with a 0.65 mm thick adjsuting washer up to the stop |

| –

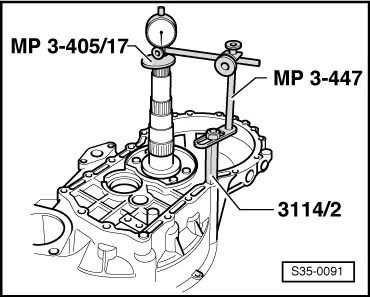

| Insert output shaft and tighten nuts for the bearing support to tightening torque → Chapter. |

| –

| Turn the output shaft 20 to 30 times in one direction. |

Note | t

| Therefore, turn it in one direction so that the rollers of the tapered-roller bearing settle in one direction. |

| t

| To this end it is also necessary to turn it 20 to 30 times. |

| t

| Otherwise the alignment result will be distorted. |

|

|

|

Note

Note Note

Note

Note

Note Note

Note