Octavia Mk1

| 1 - | Gearbox housing |

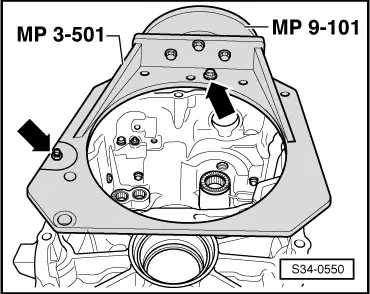

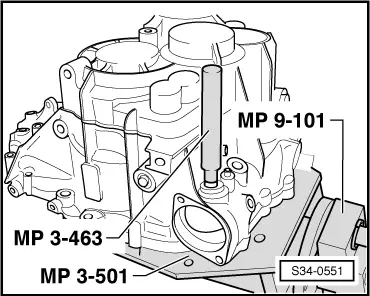

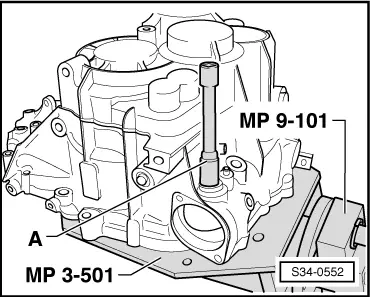

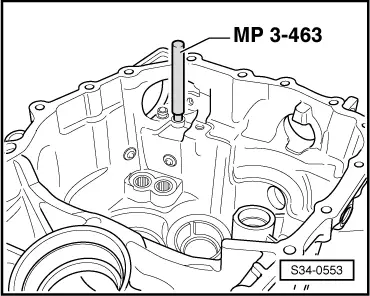

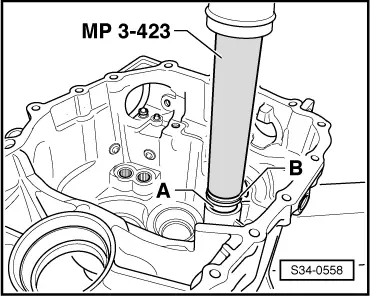

| q | clamp into the assembly stand → Fig. |

| q | when replacing: set drive shaft, output shafts and differential gear → Chapter |

| 2 - | Sealing ring |

| q | if present, always replace → Electronic Catalogue of Original Parts |

| 3 - | Oil drain plug |

| q | pay attention to different versions → Fig.: |

| t | with internal serration, 45 Nm |

| t | with hexagon socket, 30 Nm |

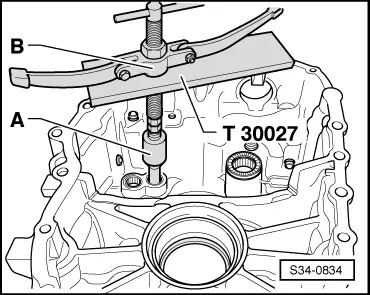

| 4 - | Serrated sleeves |

| q | extracting → Fig. |

| q | inserting → Fig. |

| 5 - | Oil filler plug |

| q | pay attention to different versions → Fig.: |

| t | with internal serration, 45 Nm |

| t | with hexagon socket, 30 Nm |

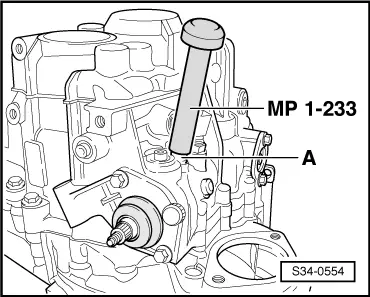

| 6 - | Locking bolt |

| q | locks the gearshift shaft → Chapter when setting the shift mechanism |

| q | extracting → Fig. |

| q | inserting → Fig. |

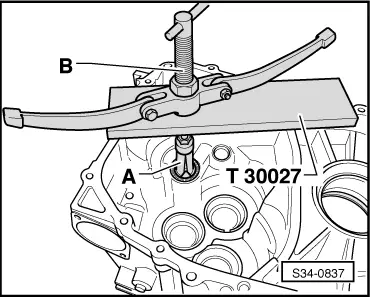

| 7 - | Bushing |

| q | for selector rods |

| q | replace after each removal |

| q | removing → Fig. |

| q | installing → Fig. |

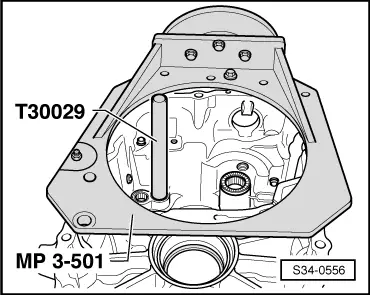

| 8 - | Needle bushing |

| q | replace after each removal |

| q | removing → Fig. |

| q | installing → Fig. |

| 9 - | Adjusting washer |

| q | for drive shaft |

| q | Setting overview → Chapter |

| 10 - | Outer ring/tapered-roller bearing |

| q | for drive shaft |

| q | removing and installing → Chapter |

| q | when replacing: set the drive shaft → Chapter |

| 11 - | Outer ring/tapered-roller bearing |

| q | for output shaft for 5th/6th gear and reverse gear |

| q | removing and installing → Chapter |

| q | when replacing: Set output shaft 5th/6th gear and reverse gear → Chapter |

| 12 - | Adjusting washer |

| q | for output shaft 5th/6th gear and reverse gear |

| q | Setting overview → Chapter |

| 13 - | Outer ring/tapered-roller bearing |

| q | for output shaft gears 1 through 4 |

| q | removing and installing → Chapter |

| q | when replacing: Set output shaft gears 1 through 4 → Chapter |

| 14 - | Adjusting washer |

| q | for output shaft gears 1 through 4 |

| q | Setting overview → Chapter |

| 15 - | Outer ring/tapered-roller bearing |

| q | for differential gear |

| q | removing and installing → Chapter and/or → Chapter |

| q | when replacing: Set the differential gear → Chapter |

| 16 - | Adjusting washer |

| q | for differential gear |

| q | Setting overview → Chapter |

| 17 - | Sealing ring |

| q | replace → Chapter |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|