Roomster

Note

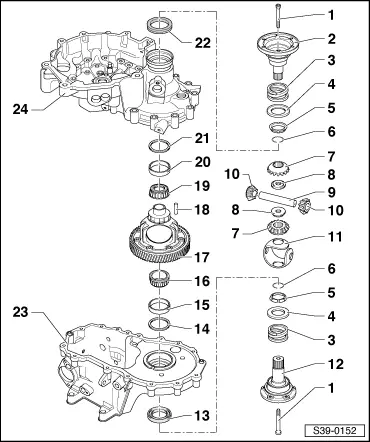

Note| t | Before installing, heat the inner ring/tapered-roller bearing with the hot-air blower -V.A.G 1416- to 100°C. |

| t | Replace both tapered-roller bearings together. |

| t | When replacing the tapered-roller bearing of the differential gear housing, gearbox housing and clutch housing adjust the differential gear → Chapter. |

| 1 - | Conical screw, 25 Nm |

| q | screw into threaded piece -Pos. 8- |

| 2 - | Right flange shaft |

| q | do not interchange, the left and right flange shafts are different |

| 3 - | Pressure spring for flange shaft |

| q | fitted behind flange shaft |

| 4 - | Thrust washer |

| q | Fitting position: Collar towards pressure spring |

| 5 - | Conical ring |

| q | Fitting position: Cone towards differential gear housing |

| 6 - | Circlip |

| q | holds the conical ring, stop disc and pressure spring in position when the flange shaft is removed |

| 7 - | Large differential bevel gear |

| q | installing → Fig. |

| 8 - | Threaded part |

| q | installing → Fig. |

| 9 - | Differential bevel gear shaft |

| q | when removing, the tensioning sleeve -Pos. 18- is cut out → Fig. |

| q | installing → Fig. |

| 10 - | Small differential bevel gear |

| q | installing → Fig. |

| 11 - | Stop disc compound |

| q | when installing moisten with gearbox oil |

| q | on certain gearboxes the stop disc compound was provided with a land → Fig. |

| 12 - | Flange shaft left |

| q | with dust guard |

| q | do not interchange, the left and right flange shafts are different |

| 13 - | Sealing ring |

| q | for left flange shaft |

| q | diameter of left and right differ |

| q | replace with installed gearbox → Chapter |

| 14 - | Adjusting washer S1 |

| q | for differential gear |

| q | always 1 mm thick |

| q | on gearboxes made out of aluminium as of production date 12.06 the adjusting washer S1 for outer ring/tapered-roller bearing is not fitted → Chapter |

| q | Bearing pedestal for outer ring/tapered-roller bearing is adapted |

| q | Assignment → Electronic Catalogue of Original Parts |

| 15 - | Outer ring/tapered-roller bearing |

| q | removing → Fig. |

| q | installing → Fig. |

| 16 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 17 - | Differential gear housing |

| q | with riveted pinion for final drive |

| q | is paired with the output shaft, replace together |

| 18 - | Tensioning sleeve |

| q | to secure the differential bevel gear shaft |

| q | is cut when removing → Fig. |

| q | installing → Fig. |

| 19 - | Inner ring/tapered-roller bearing |

| q | remove → Fig. |

| q | pressing on → Fig. |

| 20 - | Outer ring/tapered-roller bearing |

| q | pressing out → Fig. |

| q | installing → Fig. |

| 21 - | Adjusting washer S2 |

| q | for differential gear |

| q | Determine thickness → Chapter |

| 22 - | Sealing ring |

| q | for right flange shaft |

| q | diameter of left and right differ |

| q | replace with installed gearbox → Chapter |

| 23 - | Gearbox housing |

| q | is made out of aluminium or magnesium → Chapter |

| q | on gearboxes made out of aluminium as of production date 12.06 the adjusting washer S1-Pos. 14- for outer ring/tapered-roller bearing is not fitted → Chapter |

| q | Bearing pedestal for outer ring/tapered-roller bearing is adapted |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | repairing → Chapter |

| 24 - | Clutch housing |

| q | is made out of aluminium or magnesium → Chapter |

| q | Assignment → Electronic Catalogue of Original Parts |

| q | repairing → Chapter |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

WARNING

WARNING