| –

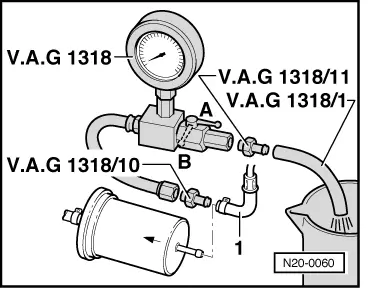

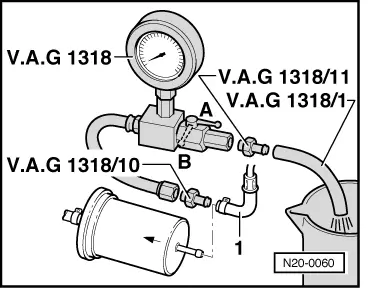

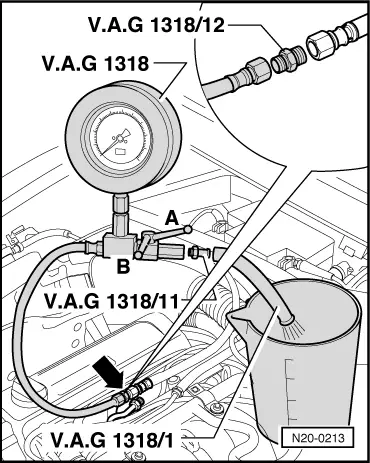

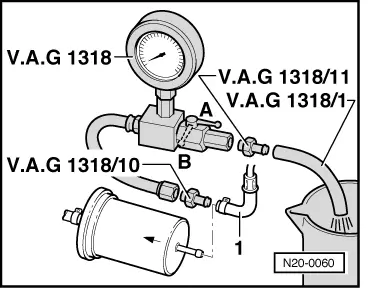

| Disconnect feed line -1- from the fuel filter inlet. |

| –

| Connect pressure gauge -V.A.G 1318 - with the adapter -1318/10 - at the hose. |

| If the minimum delivery volume now reached: |

| If the minimum delivery volume is still not reached: |

| –

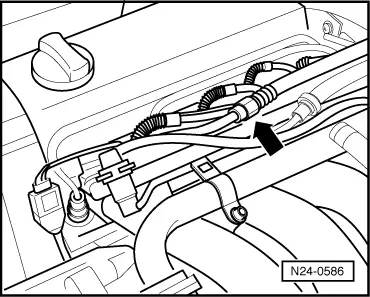

| Remove fuel delivery unit ( → Chapter) and inspect the filter strainer for soiling. |

| If you have still not found any fault up to this stage: |

| –

| Fuel pump defective, replace the fuel delivery unit → Chapter. |

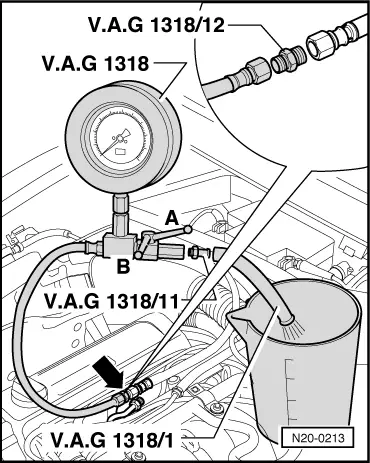

| If the required fuel delivery volume has been achieved, but a fault is still suspected in the fuel supply system (e.g. intermittent breakdown of the fuel supply). |

| –

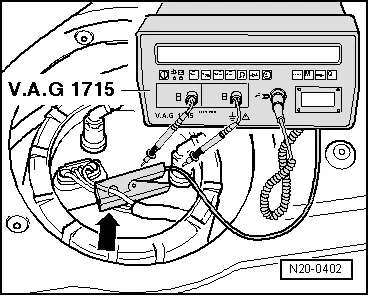

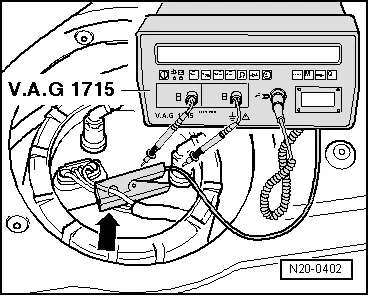

| Check the power consumption of the fuel pump as follows: |

| –

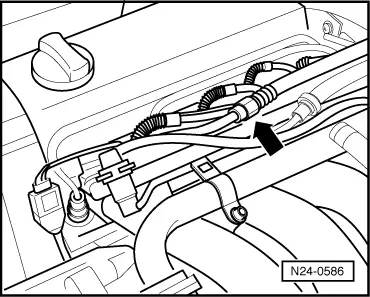

| Connect all released fuel lines. |

| –

| Remove the boot floor cover. |

|

|

|

Note

Note

Note

Note