Astra G

|

Crankshaft, Remove and Install

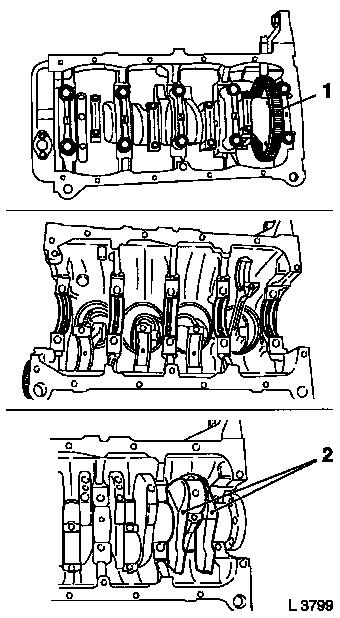

Caution Mark order of con-rod bearing caps. Remove con-rod bearing cap from con-rod. The mating surfaces of the cod-rods and the con-rod bearing caps form an individual fit and as a result must not be damaged or replaced under any circumstances. Do not lay con-rods and con-rod bearing caps on mating surfaces in order to avoid damage.

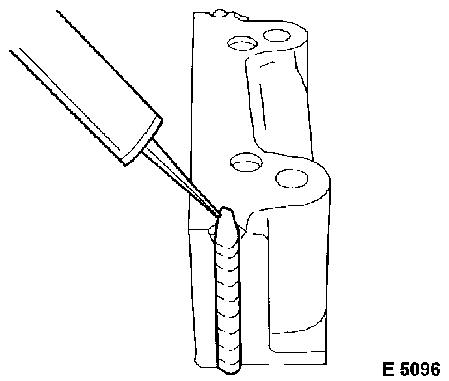

1 ) Use new fastening bolts. 2 ) After assembly of rear crankshaft bearing cap, press in adhesive sealing compound (black) from above again until it escapes from the joints |

||||||||||||||||||

|

||||||||||||||||||