|

Engine, Remove and Install

Note: The operation

"Engine, Remove and Install" is described for an X 16 XEL engine

with, AC and LHD. For models equipped differently, proceed

analogously.

Cable ties detached for removal of the engine must be reattached

at the same location on installation.

Caution

For vehicles with airbag: Turn steering to straight ahead

position, remove ignition key and engage steering lock.

Remove Remove

|

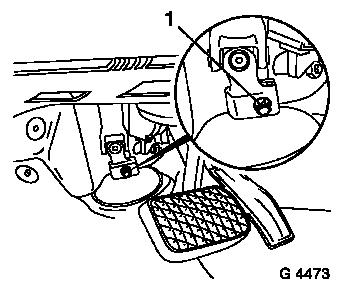

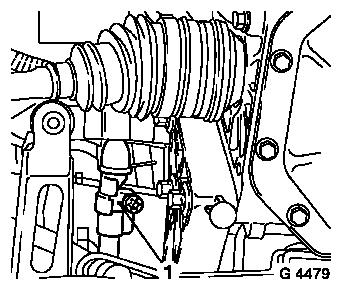

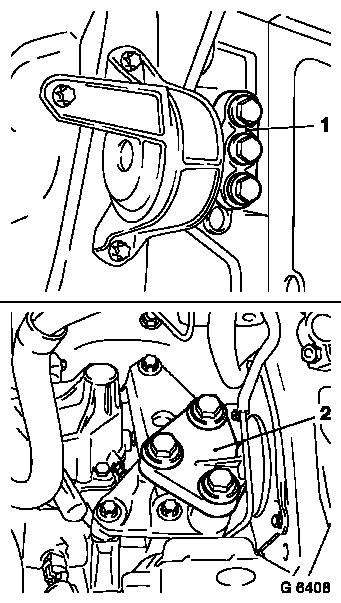

Remove clamping bolt (1) on steering column intermediate spindle

(interior).

Drain air conditioning – see operation "Air Conditioning,

Drain" in group "D".

Open coolant drain bolt – collect escaping coolant.

|

|

|

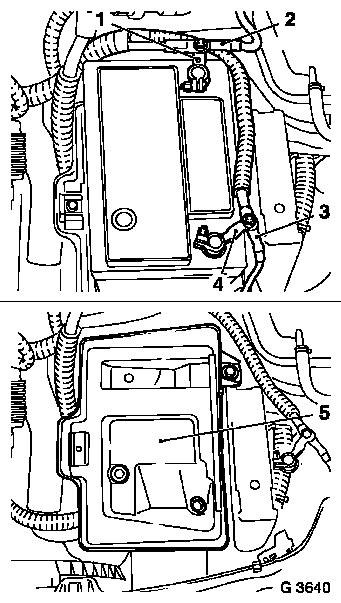

Remove engine cover.

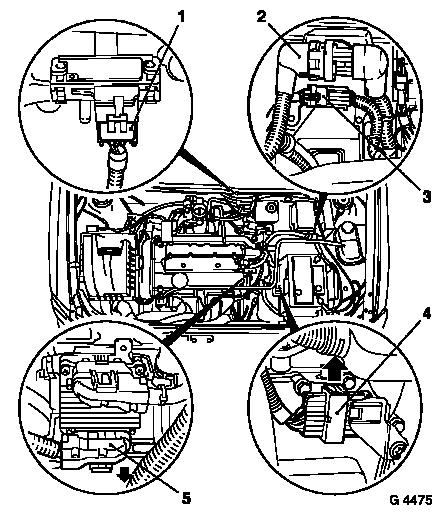

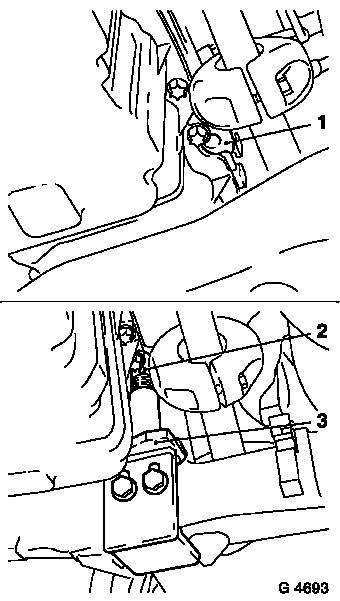

Disconnect ground cable (3) from ground connection and

disconnect ground connection (4) from battery.

Disconnect positive lead (2) from positive terminal and

disconnect positive terminal (1) from battery.

Remove battery.

Detach battery support (5) from body.

Remove air cleaner housing – see illustration "Air Ducts X

14 XE, Z 14 XE, X 16 XEL,Z 16 XE, Z 16 YNG" or "Air Ducts X 18 XE1,

Z 18 XE, Z 18 XEL".

|

|

|

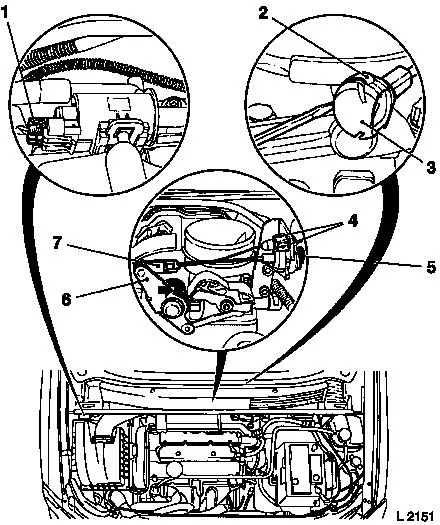

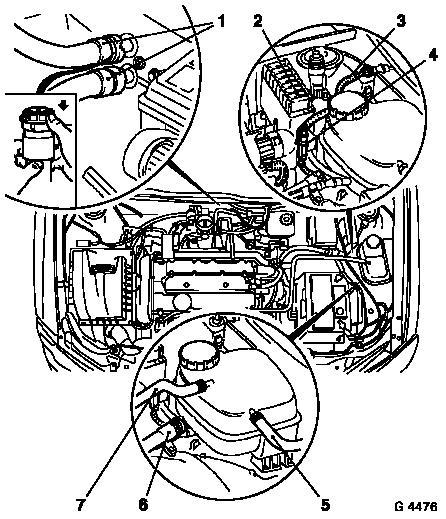

Disconnect wiring harness plug (1) from tank vent valve.

For X 18 XE1: press throttle valve lever (6) in direction of

arrow and hold in position.

Lift retainer (2) with screwdriver and remove ball socket (3)

from ball head.

If present: remove shackle for cruise control Bowden cable

(7).

Compress guide for cruise control Bowden cable at the two

retaining pins (4) and remove from bracket – lay cruise

control Bowden cable aside.

Detach retaining clamp (5) upwards and pull guide for

accelerator Bowden cable from bracket in direction of arrow and lay

aside.

|

|

|

Note: It must be

ensured that the valve support is not damaged when disconnecting

the tank vent valve hose from the valve body. Damaged valves must

be replaced.

Caution

Damaged valve supports can cause a vehicle fire as a result of

leaks.

Remove Remove

Remove tank vent valve hose (2) from tank vent valve.

Reduce fuel pressure with Pressure Tester KM-J-34730-91 via

testing port – collect escaping fuel in suitable container

– observe safety regulations and national legislation.

Remove fuel lines (3) from fuel distributor pipe.

For Z 16 YNG: Remove CNG low pressure line from CNG distributor

pipe - see operation "CNG Low Pressure Line, Remove and

Install"

Disconnect brake servo vacuum line (1) and vacuum hose for

intake manifold pressure sensor (4) from inlet manifold.

|

|

|

Wiring harness plug

- Intake manifold pressure sensor (1)

- Multiplug (twist connection) (2)

- Multiplug (green) (3)

- Engine control unit wiring harness plug (5)

- For version with automatic transmission: Transmission wiring

harness plug (4)

disconnect or detach and put cable bunch out of way.

|

|

|

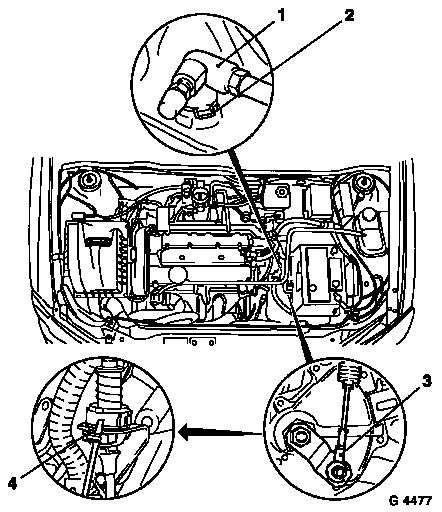

Disconnect steering cable bunch and put

out of way:

- Withdraw fuse carrier (2) from bracket

- Disconnect wiring harness plug (4)

- Detach ground cable (3) from body

Release coolant hose (1) in direction of arrow and detach from

heater core.

Detach coolant hose (7) from throttle body.

Detach coolant hose (6) from coolant pipe.

Detach coolant hose (5) from radiator.

|

|

|

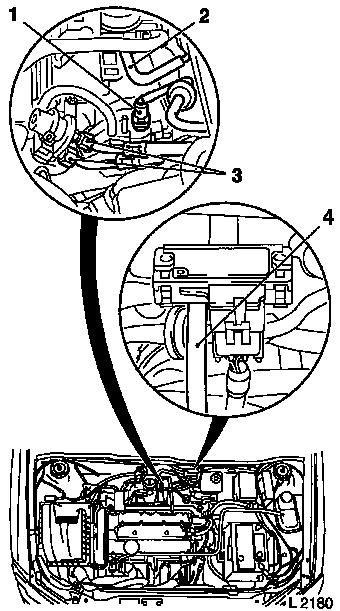

For version with manual transmission: Release pressure line with

connector (1) from pressure line for central release mechanism on

clutch housing – detach clutch pressure line for this.

Release clamp (2) with screwdriver and remove – then bend

clamp slightly together and re-insert in connector.

For version with automatic transmission: Push selector actuation

cable (3) off actuation lever. Lever out retainer (4) with

screwdriver and unclip selector actuation cable from

counterpart.

|

|

|

Remove front wheels.

Remove front panelling – see operation "Front Panelling,

Remove and Install " in group "A".

Detach swing arm (1) on both sides from spring strut support

tube – counterhold with op-ended spanner at the two flattened

surfaces.

Withdraw axle shafts on both sides from wheel hub (do not remove

from transmission) – see operation "Axle Shaft, Remove and

Install" in group "E".

Remove lower engine splash guard.

Unlock wiring harness plug (2) in direction of arrow and detach

from cooling module control unit.

Disconnect ground cable (3) from body.

|

|

|

Remove front exhaust pipe with catalytic converter and centre

muffler.

For version with manual transmission: Release clamp (1) from

shift rod and remove shift guide from shift rod.

|

|

|

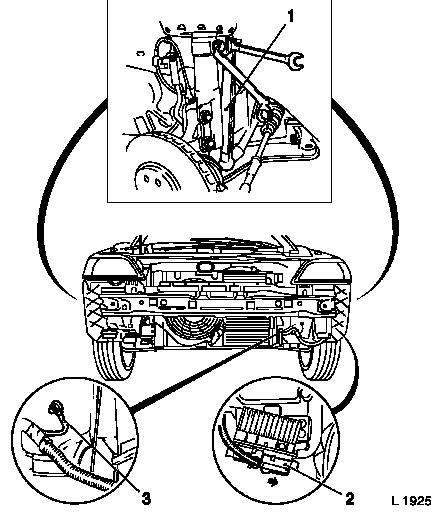

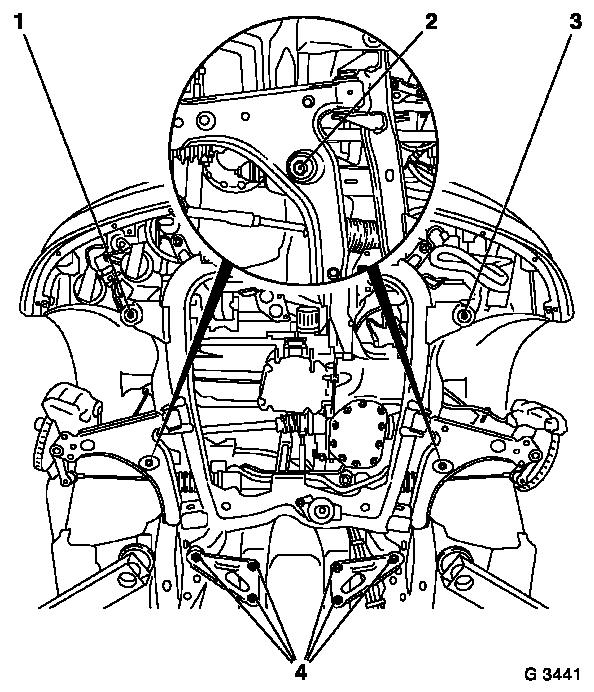

Note: The drive unit

must be aligned to the front axle body using KM-6173 and KM-6001-A

in order to ensure correct alignment of the drive unit after

releasing the fastening bolts for the right and left engine damping

blocks. The attachment of KM-6173 and KM-6001-A is described in the

following.

Install

Install

Attach KM-6173 (3) to front axle body – screw up support

bearing (2) until pin is seated flush in mount (1) on cylinder

block.

|

|

|

Release fastening bolts (arrows) for adjustment rails on

KM-6001-A (1).

Insert KM-6001-A as illustrated – pins (2) and (5) must

sit in guide holes of front axle body.

Tighten fastening bolts for adjustment rails.

Screw up front support bearing (4) and rear support bearing (3)

until contact is made with guide pins of front engine damping block

and rear engine damping block bracket – the guide pins must

seat free from play in the support bearings.

|

|

Remove Remove

|

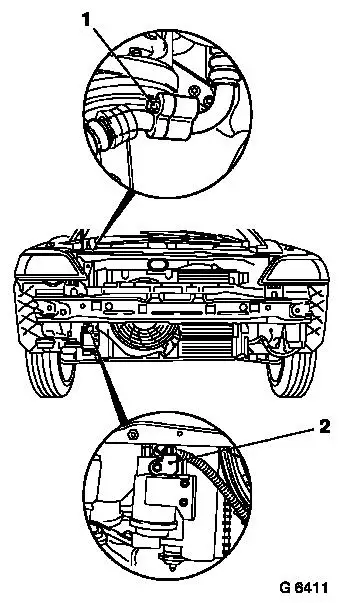

For version with air conditioning:

Remove fastening bolt (1) and disconnect refrigerant line.

Remove fastening bolt (2) and detach refrigerant line from

receiver-dryer.

|

|

|

Detach right engine damping block bracket (1) and left engine

damping block bracket (2) from engine damping block support.

|

|

Install

Install

|

Install Base Frame KM-904 with Centring Mount KM-6000 on

hydraulic jack and position free of play under front axle body (use

hydraulic jack which can be lowered at least 100 cm).

|

|

Caution

Dismantling of front axle body using an impulse or impact

screwdriver is not permissible. Note dissimilar bolt lengths.

|

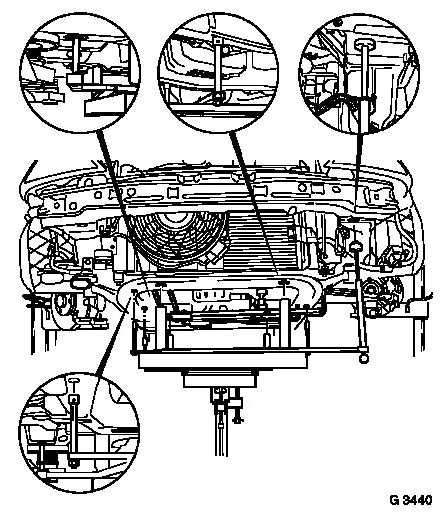

Note: For greater

clarity, the illustration shows the front axle body without

hydraulic jack and centring mount.

Remove Remove

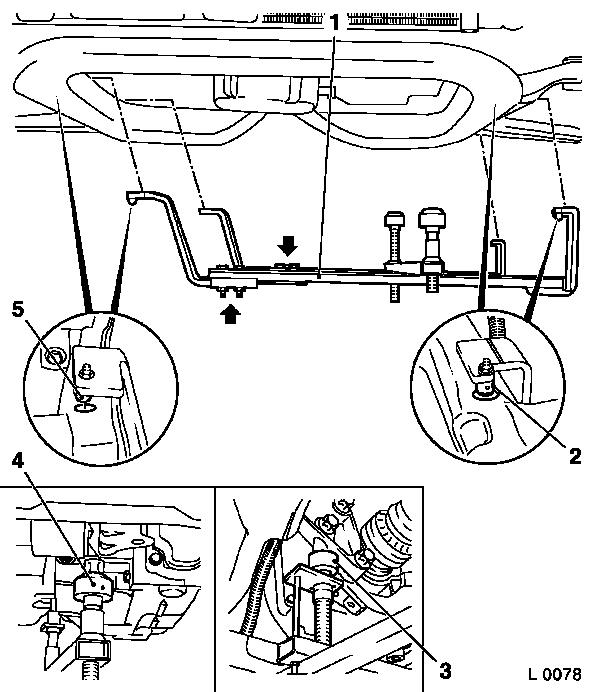

Remove six rear fastening bolts (4) on left and right. Remove

front fastening bolts on right (1) and left (3). Remove centre

fastening bolts (2).

Carefully lower front axle body with entire drive unit, steering

gear and radiator – thereby ensuring that no attaching parts

are damaged.

|

|

Caution

Ensure the threads of the captive nuts move freely before

installing front axle body with drive unit, steering gear and

radiator, replace captive nuts if necessary.

Install

Install

|

Carefully guide front axle body with entire drive unit, steering

gear and radiator into engine compartment and position free of play

on chassis – thereby ensuring that no attaching parts are

damaged.

Attach front axle body to vehicle underbody with new fastening

bolts (1- 4) – tightening torque 90 Nm / 66.5 lbf. ft. +

45° + 15°.

|

|

Caution

Installing the front axle body using an impulse or impact

screwdriver is not permissible. Note dissimilar bolt lengths and

washers.

Install

Install

Attach right engine damping block bracket to engine damping

block support – tightening torque 55 Nm / 41 lbf. ft.

Attach left engine damping block bracket to engine damping block

support – tightening torque 55 Nm / 41 lbf. ft.

For version with air conditioning:

Connect refrigerant line – tightening torque 20 Nm / 15

lbf. ft.

Attach refrigerant line to receiver-dryer – tightening

torque 20 Nm / 15 lbf. ft.

Remove Remove

Remove Engine Mount KM-6001-A and Engine Support KM-6173.

Install

Install

For version with manual transmission:

Attach shift guide using clamp to shift rod – it is only

tightened after the transmission shift linkage is adjusted.

Install front exhaust pipe with catalytic converter and centre

muffler.

Connect ground cable for cooling module control unit to

body.

Connect wiring harness plug to cooling module control unit and

lock.

Install lower engine splash guard.

Install axle shafts – see operation "Axle Shaft, Remove

and Install" in group "E".

Attach swing arms on both sides to spring strut support tube

with new fastening nuts – counterhold with op-ended spanner

at two flattened surfaces – tightening torque 65 Nm / 48 lbf.

ft.

Install front panelling – see operation "Front Panelling,

Remove and Install" in group "A".

Attach front wheels – tightening torque 110 Nm / 81 lbf.

ft.

For version with manual transmission: Attach pressure connection

for hydraulic clutch actuator to manual transmission.

For version with automatic transmission: Clip selector actuator

cable in counterpart and slide in retaining clamp. Attach selection

lever cable to actuation lever.

Attach coolant hoses – ensure correct seating. Route

steering cable bundle and attach.

For version with automatic transmission – connect

transmission wiring harness plug.

Connect wiring harness plug to engine control unit and lock.

Attach wiring harness plug to intake manifold pressure sensor

and tank vent valve.

Connect grey multiplug and twist-connection multiplug.

Attach brake servo vacuum line and vacuum hose for intake pipe

pressure sensor to intake manifold.

Attach tank vent valve hose to throttle valve body.

Attach fuel lines to fuel distributor pipe – tightening

torque 15 Nm / 11 lbf. ft.

For Z 16 YNG: Attach CNG low pressure line to CNG distributor

pipe - see operation "CNG Low Pressure Line, Remove and

Install"

If present: allow guide for cruise control Bowden cable to

engage into bracket and connect cruise control Bowden cable onto

ball head. Install guide for accelerator Bowden cable into bracket

and insert retaining clamp behind intermediate washer. Clip ball

socket for accelerator Bowden cable to ball head – ensure

that retainer engages.

Install air cleaner housing – see illustration "Air Ducts

X 14 XE, Z 14 XE, X 16 XEL, Z 16 XE, Z 16 YNG" or "Air Ducts X 18

XE1, Z 18 XE, Z 18 XEL".

Attach battery support to body- tightening torque 15 Nm / 11

lbf. ft.

Install battery and fasten to battery support.

Coat new clamp bolt for steering column intermediate shaft with

screw locking compound (red). Attach intermediate shaft to steering

column – tightening torque 22 Nm / 16.2 lbf. ft.

Connect battery electrically.

For version with AC: Charge AC – see operation "Air

Conditioning, Evacuate and Charge" in group "D".

For version with manual transmission: Bleed hydraulic clutch

– see operation "Hydraulic Clutch Actuator, Bleed

(F13/F17/F18/F23)" in group "K".

Adjust shift mechanism – see operation "Transmission Shift

Linkage, Adjust (F13/F17/F18)" in group "K".

Inspect

Inspect

Charge cooling system – see operations "Cooling System,

Charge and Bleed" and "Cooling System, Check for Leaks".

|