|

Timing Case, Remove and Install

Note: Note differing

designs! New components for DOHC-0-petrol engines:

TN 2004 - New components in MY 2004

- TN 2005 - Camshaft control from end of MY 2004 to MY 2005

- TN 2005 - Camshaft control from MY 2005

- TN 2005 Adjusting the phase sensor disc

- TN - 2005 Camshaft sensor

- TN 2005 - Timing chain tensioner

Note: The timing case

must be removed and installed for the operations listed in the

following:

|

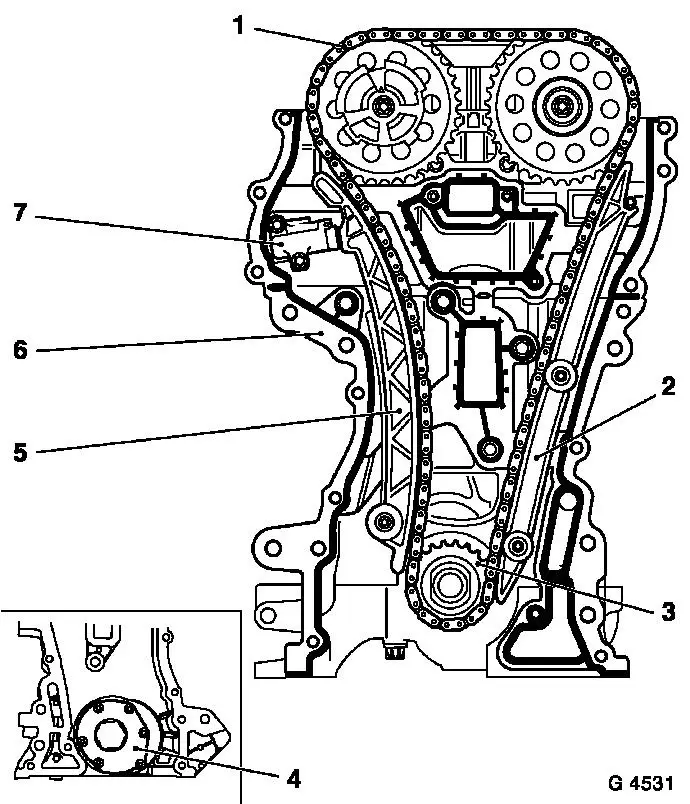

1

|

Timing Chain, Remove and Install

|

|

|

|

|

2

|

Guide Rails, Remove and Install

|

|

|

|

|

3

|

Crankshaft Sprocket, Remove and Install

|

|

|

|

|

4

|

Oil Pump, Remove and Install

|

|

|

|

|

5

|

Tension Rail, Remove and Install

|

|

|

|

|

6

|

Timing Case Gasket, Replace

|

|

|

|

|

7

|

Chain Tensioner, Remove and Install

|

|

|

Remove Remove

Disconnect earth cable from battery.

Remove oil pan – see operation "Oil Pan, Remove and

Install".

Remove air cleaner housing with hot film mass air flow meter and

air intake cover - see illustration "Air Ducts X 12 XE" or "Air

Ducts Z 12 XE" or "Air Ducts Z 14 XEP".

Remove ribbed V-belts – see operation "Ribbed V-belts,

Remove and Install".

Remove ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner, Remove and Install".

Remove alternator – see operation "Alternator, Remove and

Install".

Open coolant drain bolt – collect escaping coolant.

|

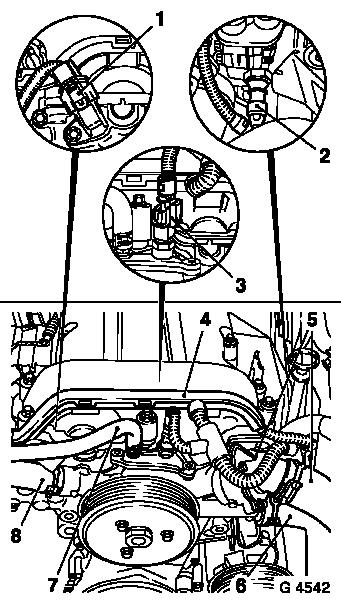

Remove thermostat housing and coolant hose (5) from coolant pump

and radiator.

Detach coolant hoses (6), (7) and (8) from coolant pump.

Disconnect wiring harness plug from camshaft sensor (1), oil

pressure switch (2) and coolant temperature sensor (3).

Unclip wiring trough (4) from cylinder head cover and lay aside

to rear.

|

|

|

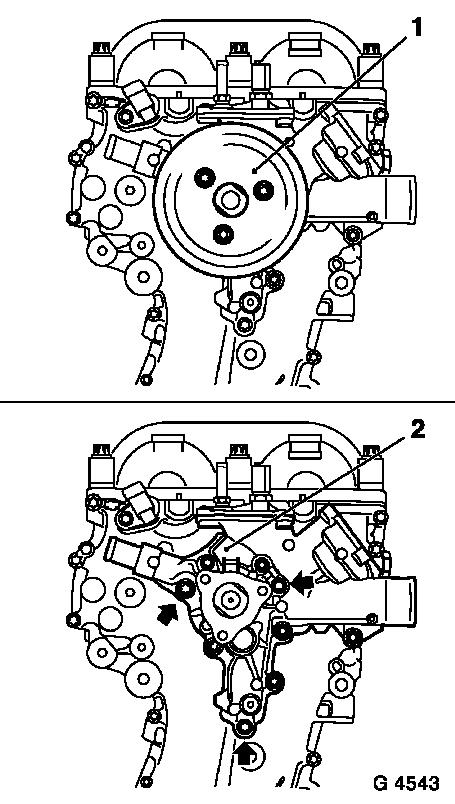

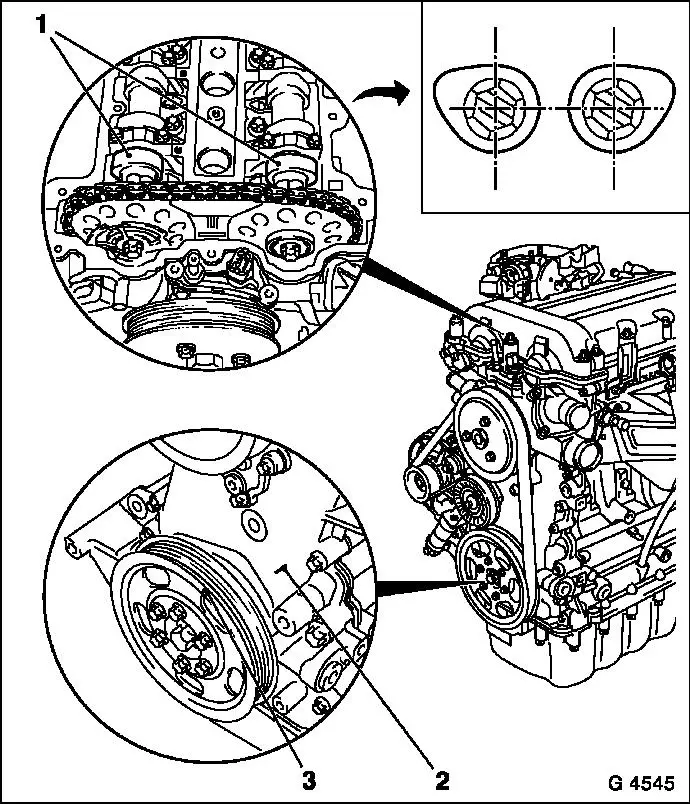

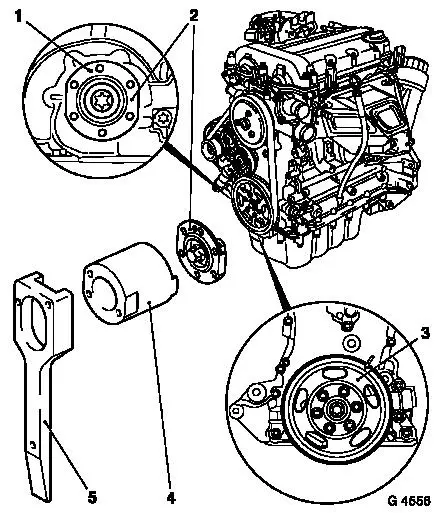

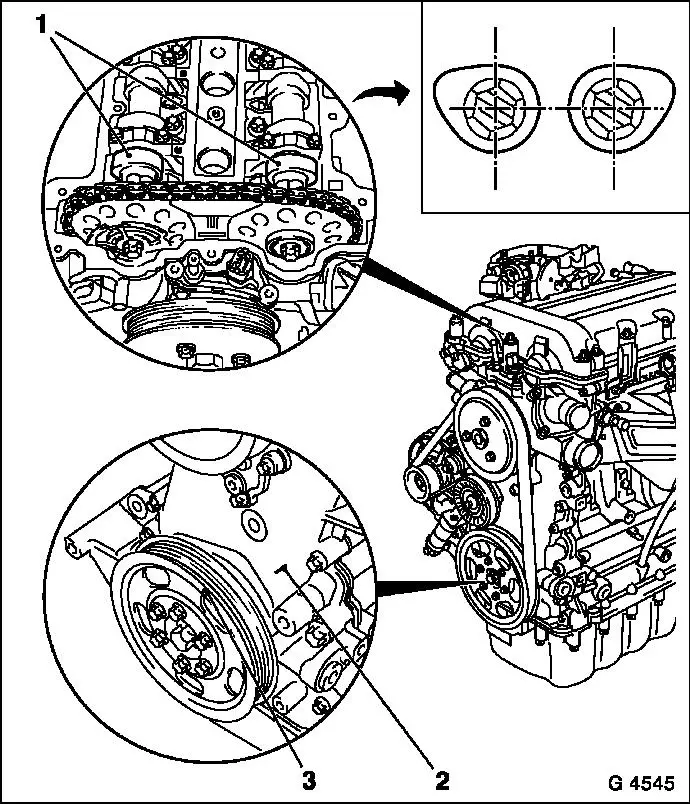

Detach pulley (1) from coolant pump.

Caution

Note guide sleeves when removing coolant pump.

Remove Remove

Detach coolant pump (2) from timing case and note dissimilar

length bolts (arrows = short bolts).

|

|

For version with air conditioning: Detach compressor from timing

case and cylinder block and lay aside to front.

Caution

The air conditioning system remains sealed.

Remove Remove

|

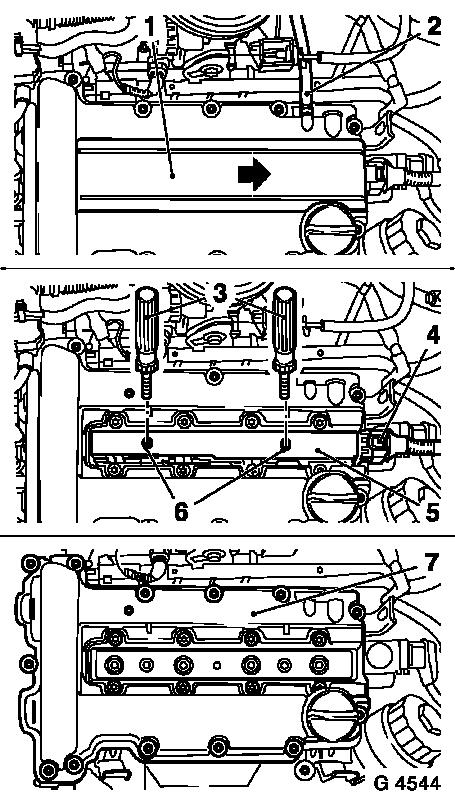

Detach engine vent hose (2) from cylinder head cover.

Disconnect wiring harness plug (4) from ignition module.

Detach ignition module cover (1) from cylinder head cover in

direction of arrow.

Remove fastening bolts (6) and disconnect ignition module (5)

from spark plugs using KM-6009 (3) – do not tilt as otherwise

the spark plug connectors can be damaged.

Detach cylinder head cover (7) from cylinder head.

|

|

Adjust Adjust

Turn crankshaft slowly and smoothly.

Move crankshaft in direction of engine rotation to just before

"1st Cylinder TDC" position using fastening bolt for crankshaft

hub.

Inspect

Inspect

|

The mark (3) on the crankshaft pulley is located just before the

lug (2) on the timing case.

In this position the cams for the 1st cylinder (1) are located

just before "TDC" (both cams point outwards).

|

|

Remove Remove

|

Remove crankshaft belt pulley (1) – counterhold at the

fastening bolt for the crankshaft hub.

Release fastening bolt for crankshaft hub (2) (do not remove)

– attach KM-6013 (3) for this and counterhold with KM-956

(4).

|

|

|

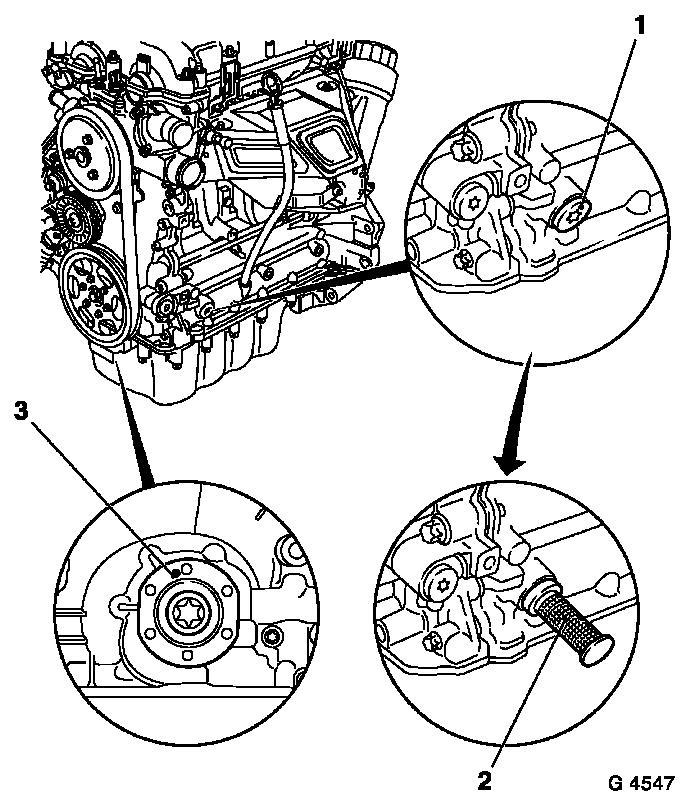

Detach closure bolt (1) for cylinder block base plate.

Adjust Adjust

Insert KM-952 (2) into opening and, at the same time, at the

fastening bolt of the crankshaft hub, slowly further turn

crankshaft in the engine rotational direction until KM-952 engages

in base plate of cylinder block or crankshaft webs to the stop.

Inspect

Inspect

In this position, the marking (3) on the crankshaft hub must

point upwards.

|

|

Install

Install

|

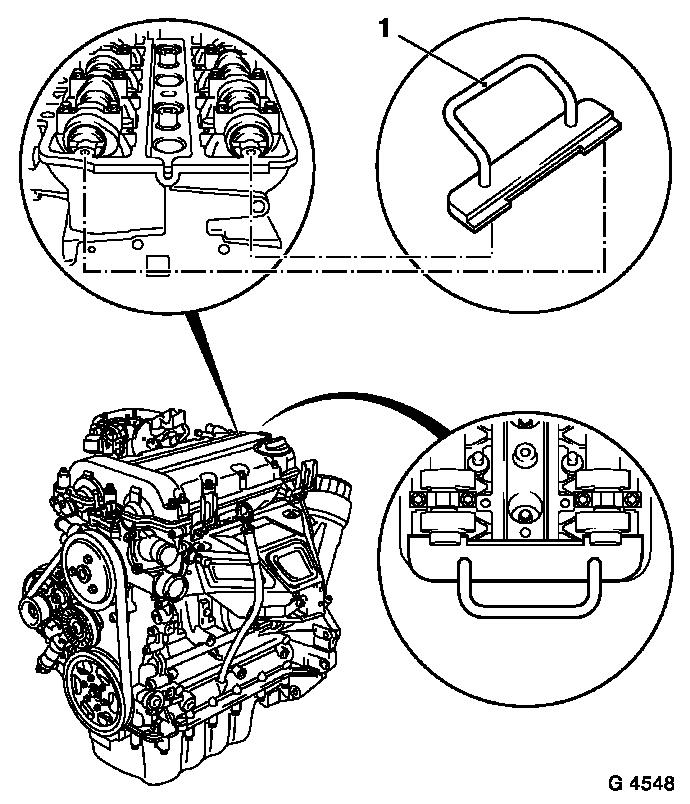

Insert KM-953 (1) into camshaft – KM-953 must engage in

grooves of camshafts to the stop.

|

|

Remove Remove

|

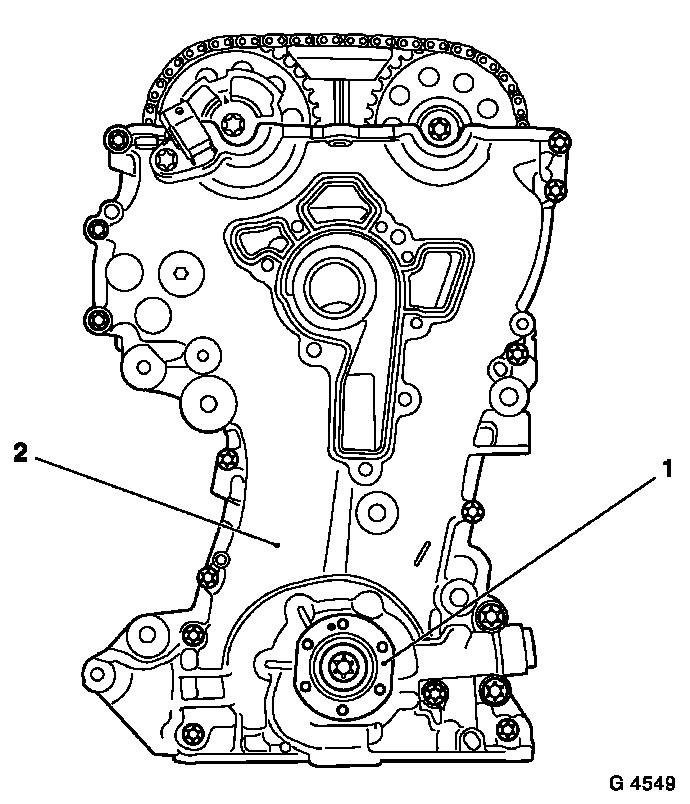

Remove crankshaft hub (1).

Detach timing case (2) from cylinder head, cylinder block and

cylinder head base plate.

|

|

|

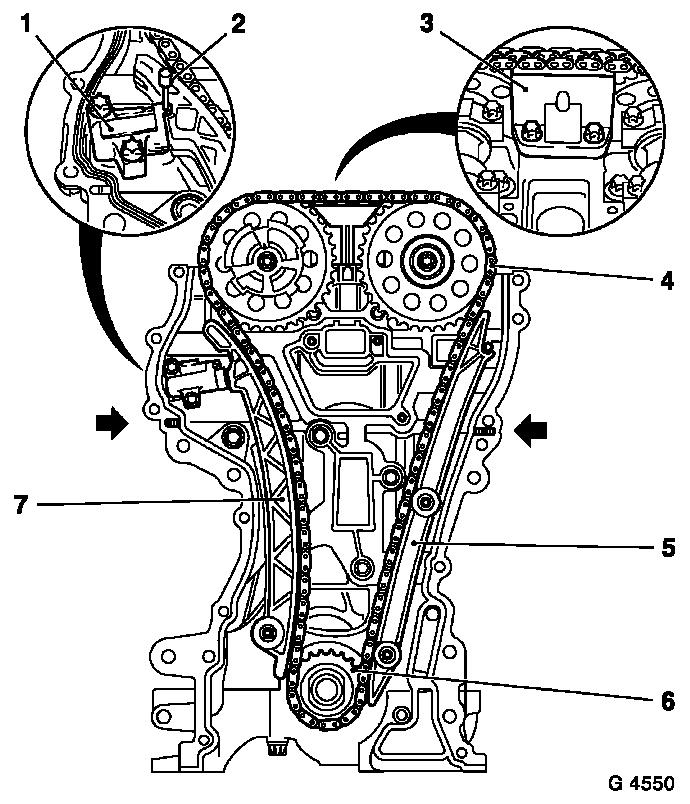

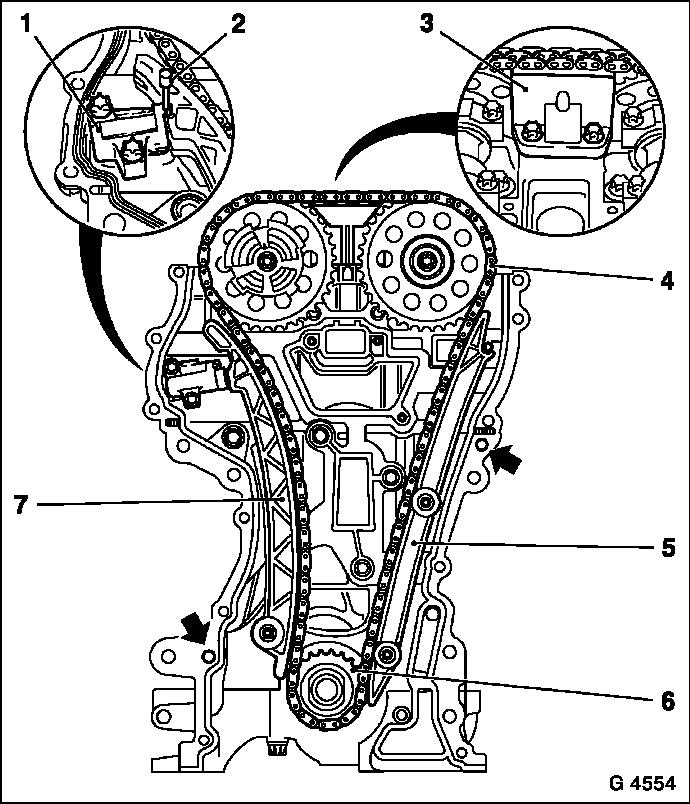

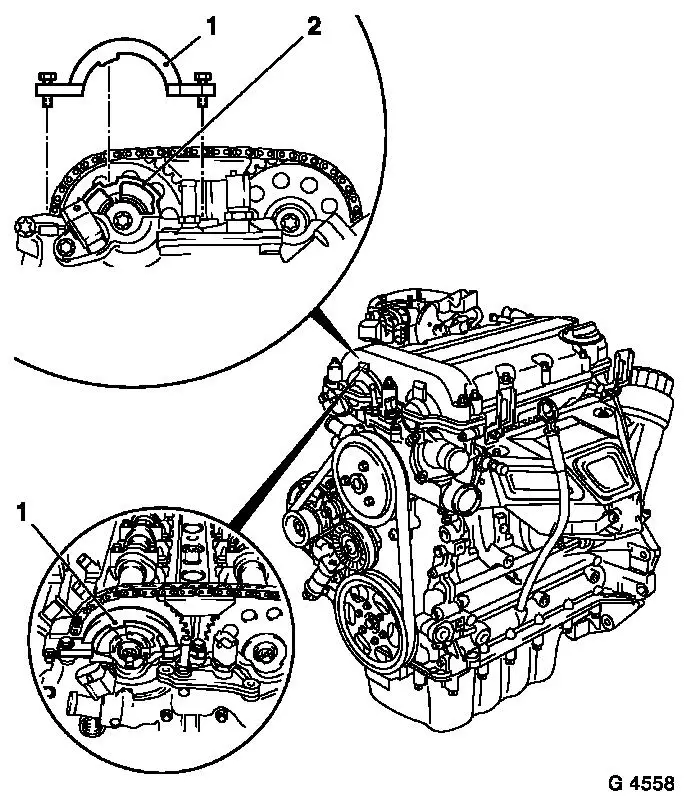

Push back chain tensioner (1) and lock with KM-955-1 (2).

Remove sliding rail (3), guide rail (5) and tension rail

(7).

Timing chain (4), drive sprocket (6) and timing case gasket.

Clean Clean

Clean sealing surfaces and remove gasket remnants.

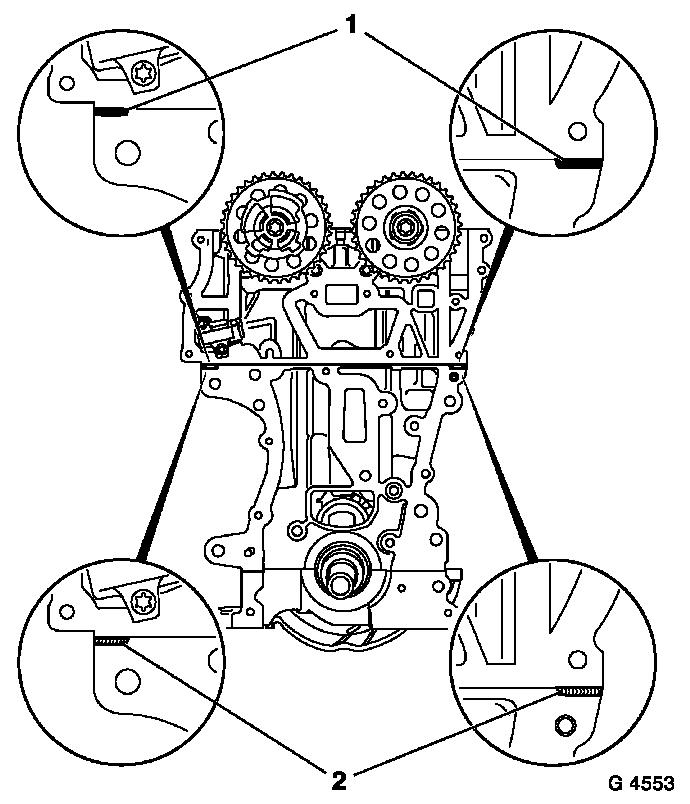

Caution

If a two-part timing case gasket has been used, sealant must be

removed in the vicinity of the cylinder head gasket (arrows).

|

|

Remove Remove

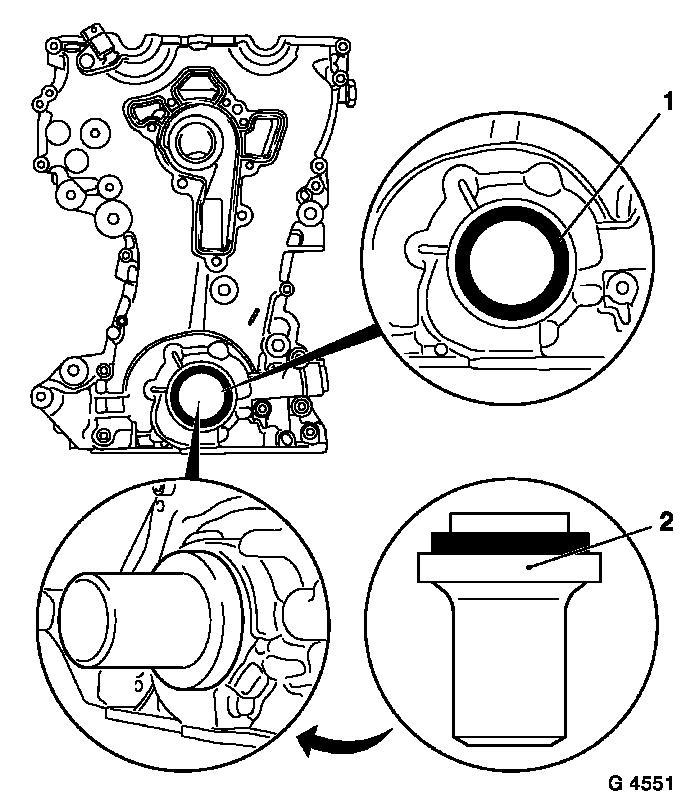

|

Lever seal ring (1) out of timing case with suitable tool.

Caution

Do not damage sealing surfaces.

Clean Clean

Clean sealing surfaces and remove gasket remnants.

Install

Install

Slide seal ring on KM-960 (2).

Drive seal ring flush into timing case using KM-960.

|

|

Remove Remove

|

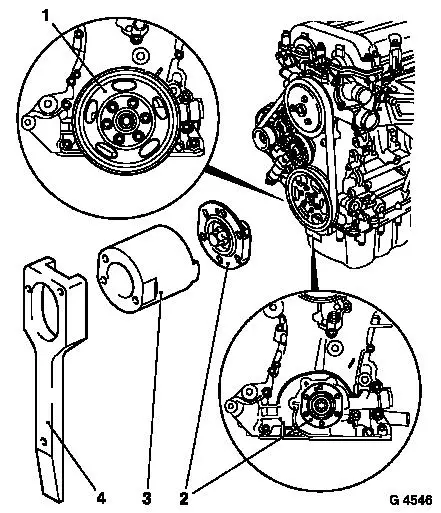

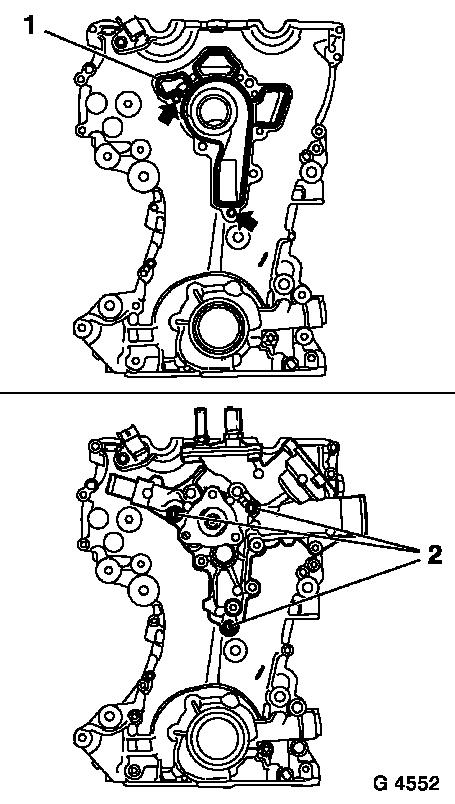

Insert new coolant pump (1) seal into timing case.

Caution

Ensure guide sleeves (arrows) are seated correctly.

Install

Install

Attach coolant pump to timing case with short bolts (2) –

tightening torque 8 Nm / 6 lbf. ft.

|

|

Caution

|

Cut off elastomer projections of cylinder head gasket (1) so

they are flush and replace with an approx. 1 mm thick bead of

silicon sealant (grey) (2).

The bead of silicon sealant (grey) (2) can be applied directly

if there is no protruding elastomer.

The timing case must be mounted within 10 minutes of applying

the silicon sealant (grey).

|

|

Install

Install

|

Install new timing case gasket – ensure correct seating of

guide sleeves (arrows). Place drive gear (6) onto crankshaft.

Install timing chain (4) on drive sprocket and camshaft

sprockets. Thereby ensure that tension side (exhaust side) of

timing chain is tensioned.

Attach tension rail (7) to cylinder block – tightening

torque 20 Nm / 15 lbf. ft.

Attach guide rail (5) to cylinder block – tightening

torque 8 Nm / 6 lbf. ft.

Attach sliding rail (3) to cylinder head – tightening

torque 8 Nm / 6 lbf. ft.

Remove Remove

Remove KM-955-1 (2) out of chain tensioner (1).

|

|

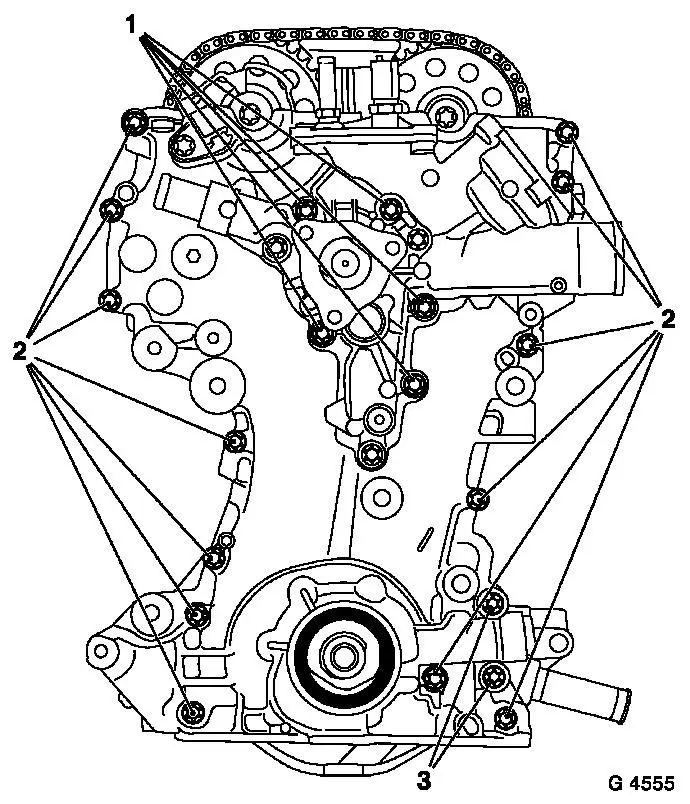

Caution

Observe installation sequence.

Install

Install

Attach timing case.

Installation sequence:

- Hand-tighten all fastening bolts.

- Attach coolant pump/ timing case fastening bolts (1) to

cylinder head and cylinder block – tightening torque 8 Nm / 6

lbf. ft.

- Attach timing case fastening bolts (2) and (3) to cylinder

head, cylinder block and to base plate of cylinder block.

Attach timing case with M6 fastening bolts (2) to cylinder head,

cylinder block and to base plate of cylinder block- tightening

torque 8 Nm / 6 lbf. ft.

Attach timing case with M10 fastening bolts (3) to cylinder

block, and base plate of cylinder block- tightening torque 35 Nm /

26 lbf. ft.

|

|

Caution

Remove KM-952 and KM-953 – Special Service Tools must not

be used to counterhold.

|

Ensure installation position of crankshaft hub (2) is correct

– mark (1) must point upwards.

Install

Install

Attach crankshaft hub to crankshaft with new fastening bolts

– attach KM-6013 (4) for this operation and counterhold with

KM-956 (5) – tightening torque 150 Nm / 111 lbf. ft. +

45°.

Attach crankshaft belt pulley (3) to crankshaft hub –

counterhold at the fastening bolts for the crankshaft hub –

tightening torque 8 Nm / 6 lbf. ft.

|

|

Adjust Adjust

Move crankshaft approx. 720° in direction of engine rotation

to just before "1st Cylinder TDC" position using fastening bolt for

crankshaft hub.

Inspect

Inspect

|

The mark (3) on the crankshaft pulley is located just before the

lug (2) on the timing case.

In this position, the cams for the 1st cylinder are located just

before "TDC" (both cams point outwards).

|

|

Adjust Adjust

Turn crankshaft slowly and smoothly.

|

Insert KM-952 (3) into opening and, at the same time, at the

fastening bolt of the crankshaft hub, slowly further turn

crankshaft in the engine rotational direction until crankshaft

locking pin engages in base plate of cylinder block or crankshaft

webs to the stop.

Inspect

Inspect

In this position, the mark (2) on the crankshaft pulley must be

flush with the lug (1) on the timing case.

|

|

Inspect

Inspect

|

Insert KM-953 (1) into camshaft – KM-953 must engage in

grooves of camshafts to the stop.

Note: If KM-953

cannot be inserted, then a basic adjustment should be performed

– see operation "Timing, Adjust".

|

|

|

Position KM-954 (1) on the phase sensor disc (2) and attach to

timing case.

Note: If KM-954

cannot be inserted, then a basic adjustment should be performed

– see operation "Timing, Adjust".

|

|

Remove Remove

Remove or disassemble KM-954, KM-953 and KM-952.

Install

Install

Install closure bolt in cylinder block base plate with new seal

ring – tightening torque 60 Nm / 44 lbf. ft.

Clean Clean

Clean sealing surfaces and remove gasket remnants.

|

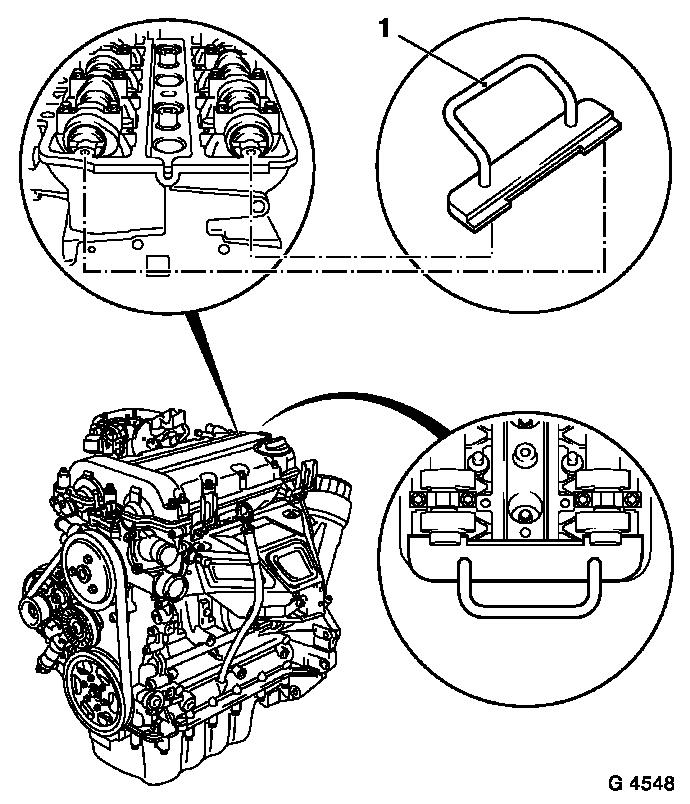

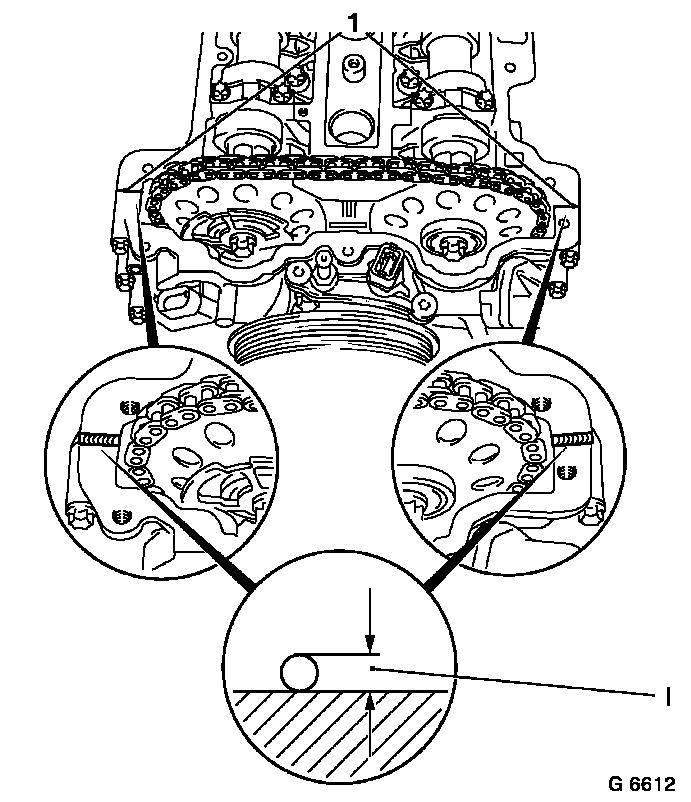

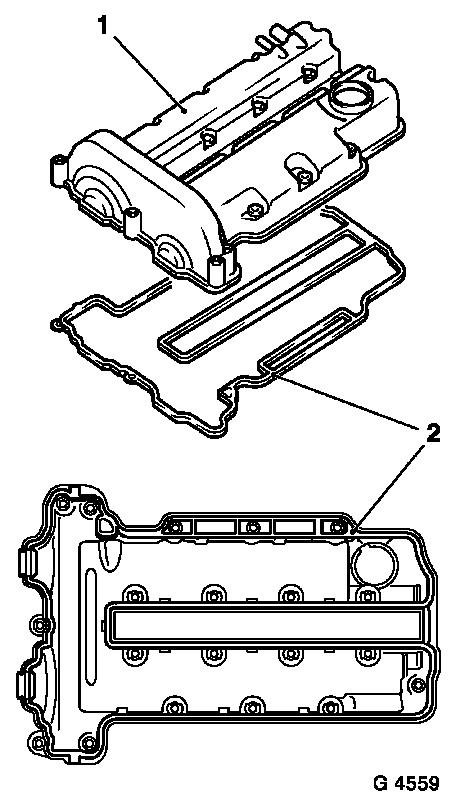

Procedure

Cut off protruding cylinder head gasket (1) flush with cylinder

head/ timing case and replace with an approx. 2 mm thick bead of

silicon sealant (grey) (dimension I).

Caution

The cylinder head cover must be mounted within 10 minutes of

applying the silicon sealant (grey).

|

|

Install

Install

|

Insert new seal (2) in cylinder head cover (1).

Attach cylinder head cover to cylinder head – tightening

torque 8 Nm / 6 lbf. ft.

Connect ignition module to spark plugs and attach to cylinder

head – tightening torque 8 Nm / 6 lbf. ft.

Attach ignition module cover to cylinder head cover.

Connect wiring harness plug to ignition module.

Attach engine vent hose to cylinder head cover.

|

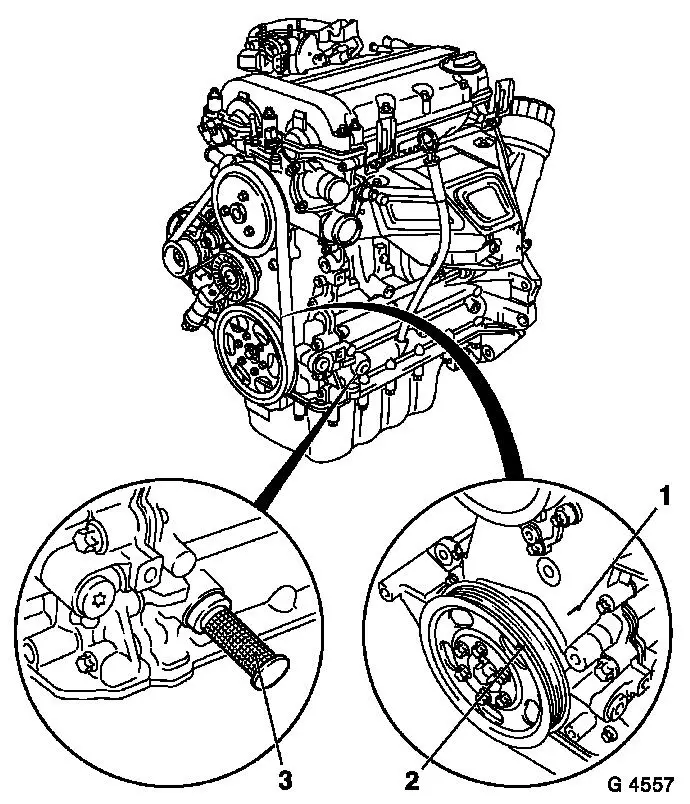

|

For version with air conditioning: Attach compressor to timing

case and cylinder block – tightening torque 20 Nm / 15 lbf.

ft.

Attach pulley to coolant pump – tightening torque 20 Nm /

15 lbf. ft.

Attach or connect wiring harness plug to coolant temperature

sensor, camshaft sensor and to oil pressure switch.

Clip wiring trough to cylinder head cover.

Attach coolant hoses to coolant pump.

Attach upper coolant hose to radiator and attach thermostat

housing to coolant pump with new gasket – tightening torque 8

Nm / 6 lbf. ft.

Install alternator – see operation "Alternator, Remove and

Install".

Install ribbed V-belt tensioner – see operation "Ribbed

V-belt Tensioner, Remove and Install".

Install ribbed V-belt – see operation "Ribbed V-belt,

Remove and Install".

Install air cleaner housing with hot film mass air flow meter

and air intake cover - see illustration "Air Ducts X 12 XE" or "Air

Ducts Z 12 XE" or "Air Ducts Z 14 XEP".

Install oil pan – see operation "Oil Pan, Remove and

Install".

Connect earth cable to battery.

Inspect

Inspect

Charge cooling system – see operations "Cooling System,

Charge and Bleed" and "Cooling System, Check for Leaks".

|