|

End Shield, Dismantle and Assemble (F17+)

Note: Transmission

remains installed.

Remove Remove

|

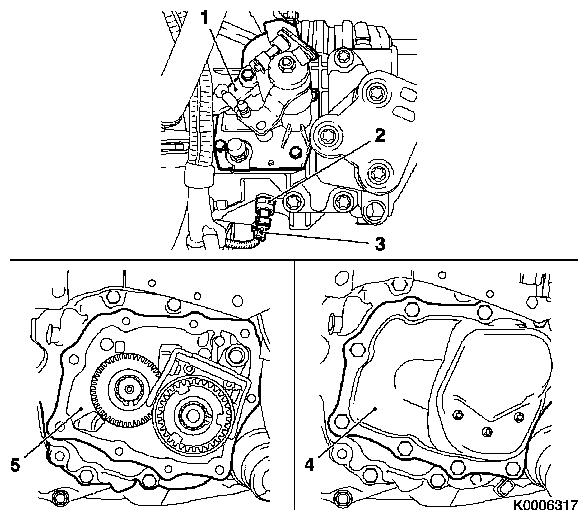

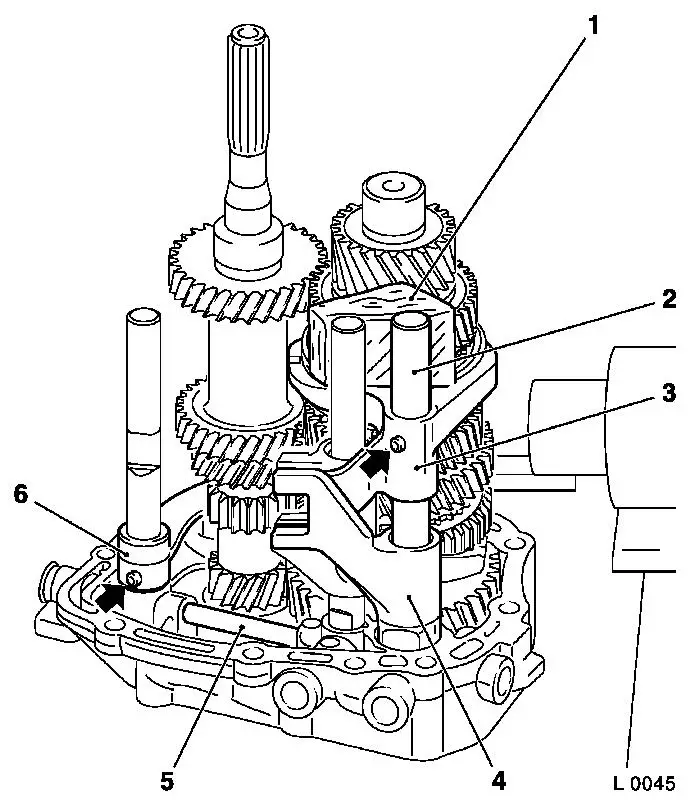

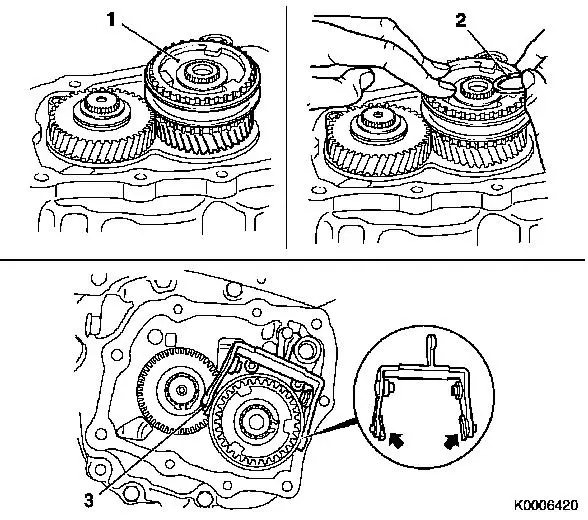

| 1. |

Remove shift mechanism cover (1)

| • |

see operation "Gearshift Cover, Remove and Install and/or Seal

(F13/F17/F17+/F18)"

|

|

| 2. |

Remove reversing lamp switch (2)

| • |

Disconnect reversing lamp (3) switch wiring harness plug

|

| • |

Unscrew reversing lamp switch

|

|

| 3. |

Remove end shield (4) cover

| • |

See operation "Gasket for End Shield Cover, Replace

(F13/F17/F17+/F18)".

|

|

| 4. |

Remove end shield (5)

| • |

See operation "Gasket for End Shield, Replace

(F13/F17/F17+/F18)".

|

|

|

|

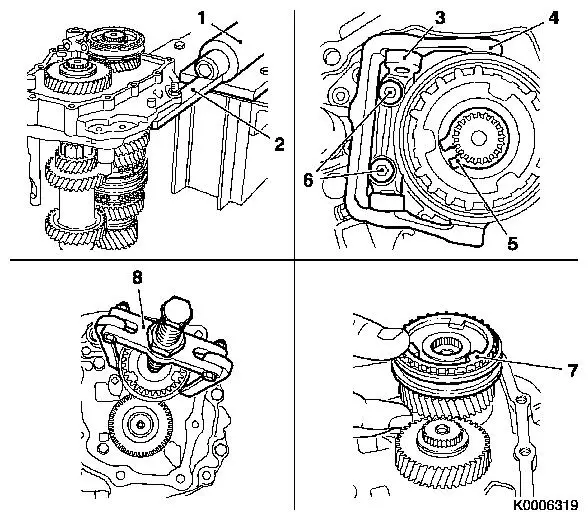

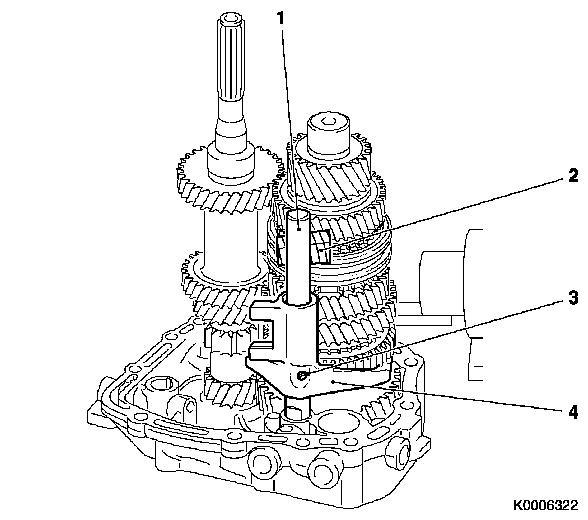

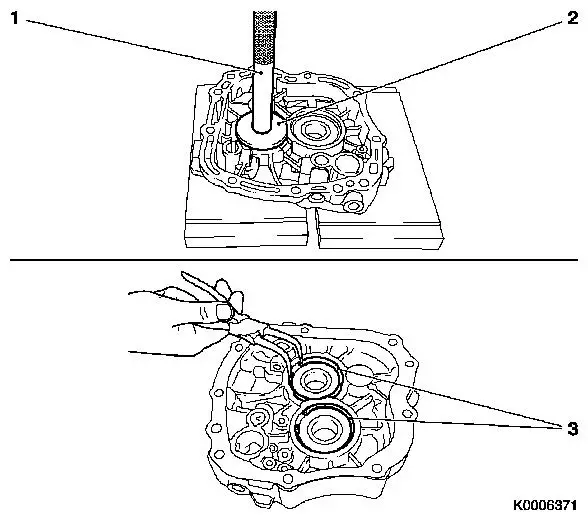

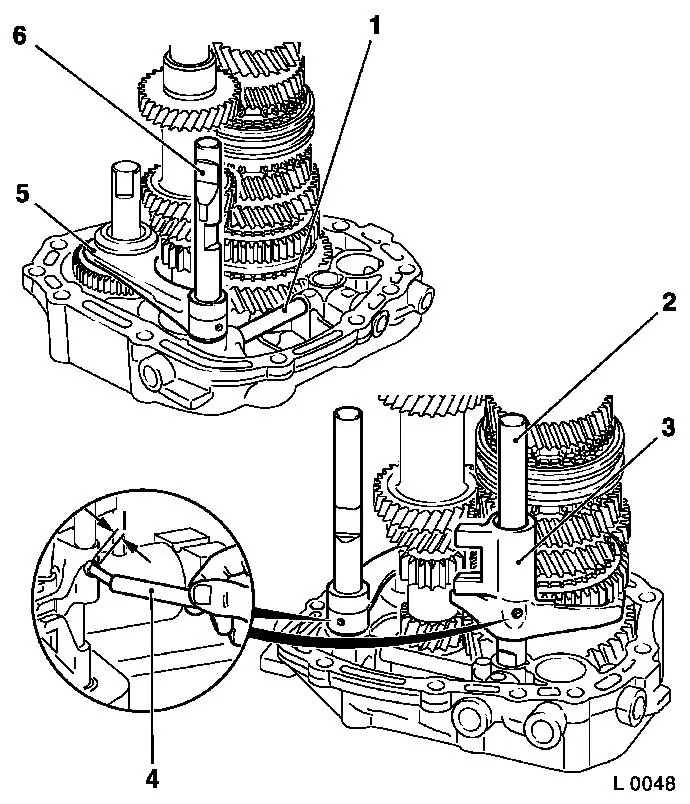

| 5. |

Attach end shield to KM-113-2

| • |

Attach end shield to KM-552 (2)

|

| • |

Attach end shield to KM-113-2 (1)

using KM-552

|

|

Important: Micro-encapsulated

fastening bolts. If fastening bolts are stiff, heat end shield with

hot-air dryer to approximately 80 °C.

|

| 6. |

Remove bearing support (3) with rocker arm (4) from end

shield

|

| 7. |

Remove 5th gear (driven)

| • |

Detach retainer (5) from synchro body

|

| • |

Pull off 5th gear and synchromesh body 5th gear from main shaft

using KM-559-A (8)

|

| • |

remove needle cages for 5th gear

|

|

|

|

Important: Micro-encapsulated

fastening bolts. If fastening bolts are stiff, heat end shield with

hot-air dryer to approximately 80 °C.

|

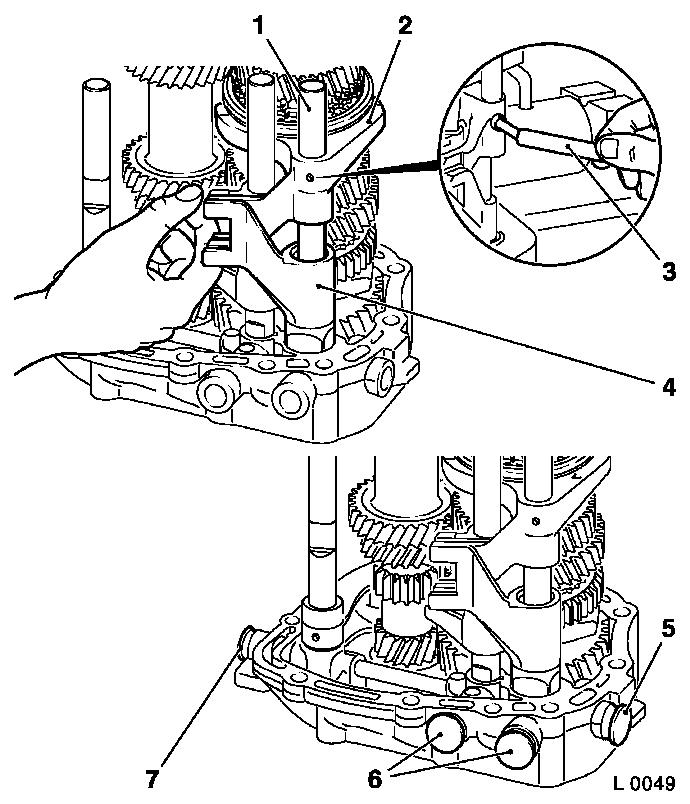

| 8. |

Remove bearing support (2) with pawl (1) from end shield

| • |

Remove 2x bolts (arrow)

|

|

| 9. |

Engage 2 gears

| • |

Engage reverse gear and 4th gear to block transmission

|

|

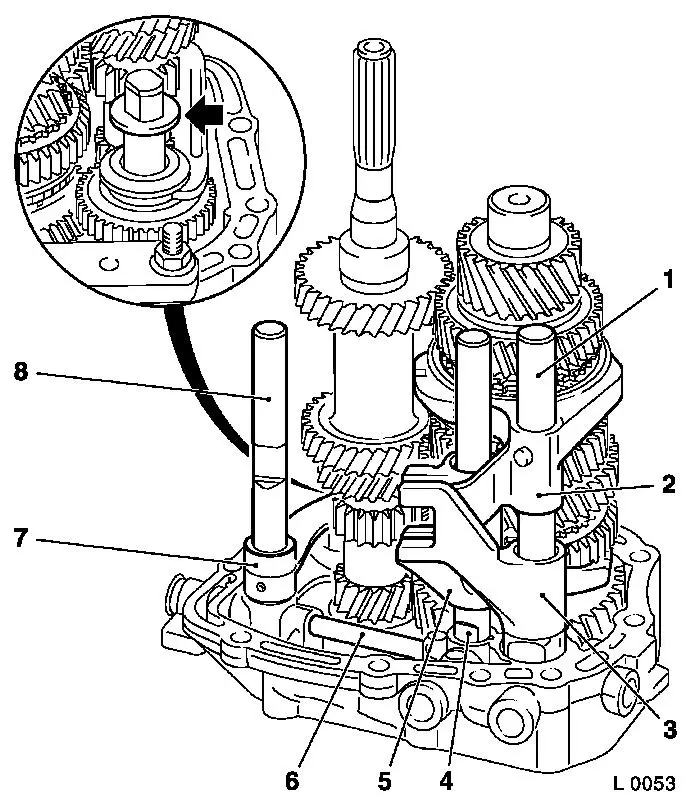

| 10. |

Remove 5th gear (driven) (5)

| • |

Remove retaining ring (7) from drive shaft (6)

|

| • |

Locate KM-553-A (4) with thrust piece

(3) on drive shaft and gear

Note: Check for proper

seating

|

| • |

Pull off 5th gear from main shaft using KM-553-A

|

|

|

|

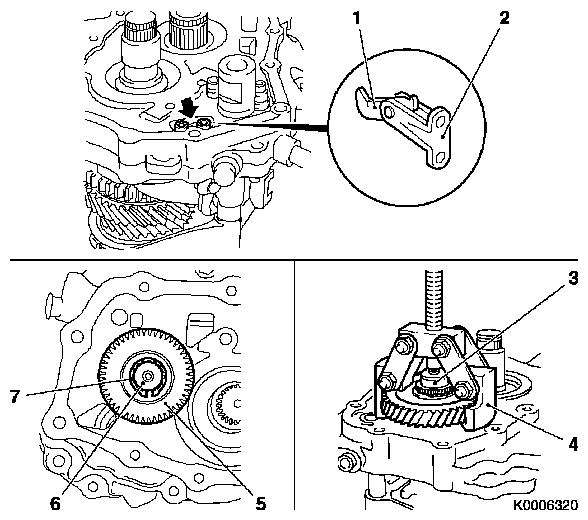

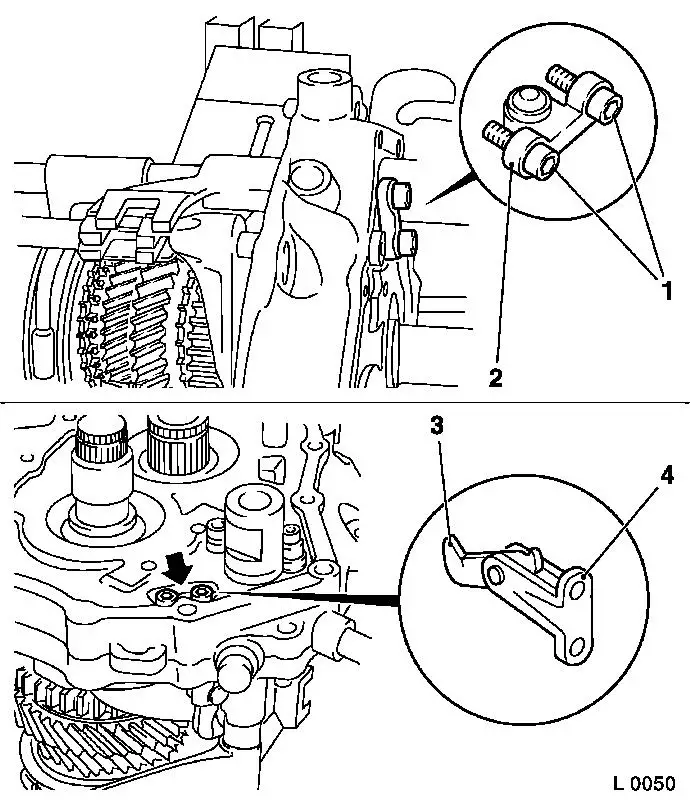

| 11. |

Remove locking plugs (arrow)

| • |

Pull plug out of end shield using KM-727 (2) and KM-328-B

(1)

|

|

Important: Micro-encapsulated

fastening bolts. If fastening bolts are stiff, heat end shield with

hot-air dryer to approximately 80 °C.

|

| 12. |

Remove bridge for lock pin (3)

| • |

Remove 2x bolts (4)

Note: Turn end shield

onto its side

|

| • |

Engage 2nd and 5th gears (with shift driver)

|

| • |

Engage 3rd gear and remove bridge

|

|

|

|

Important: Relieve pressure on

shifter rod guides – for this, support shifter rods above

with wood (1)

|

| 13. |

Remove shift fork, 3rd/4th gear and reverse gear

| • |

Drive roll pins out of 3rd/4th gear shift fork (3) and reverse

gear shift fork (6) using KM-308

|

| • |

Take out shift rod (2), shift rod reverse gear and shift

fork

|

|

| 14. |

Remove gear shift driver

| • |

Remove 5th gear shift driver (4) from end shield

|

|

| 15. |

Remove locking pins (5)

| • |

Remove roll pin for catch from end shield

|

|

|

|

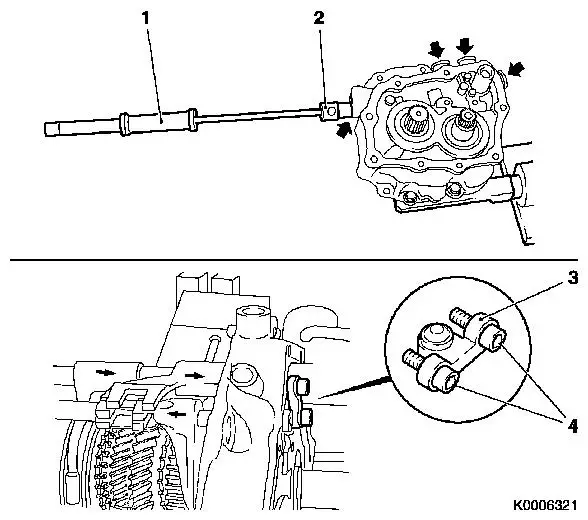

Important: Relieve pressure on

shifter rod guides – for this, support shifter rods (1) above

with wooden wedge (2)

|

| 16. |

Remove 1st/2nd gear shift fork

| • |

Drive roll pin (3) out of 1st/2nd gear shift fork (4) using

KM-308

|

| • |

Take out shift fork with shift rod

|

|

|

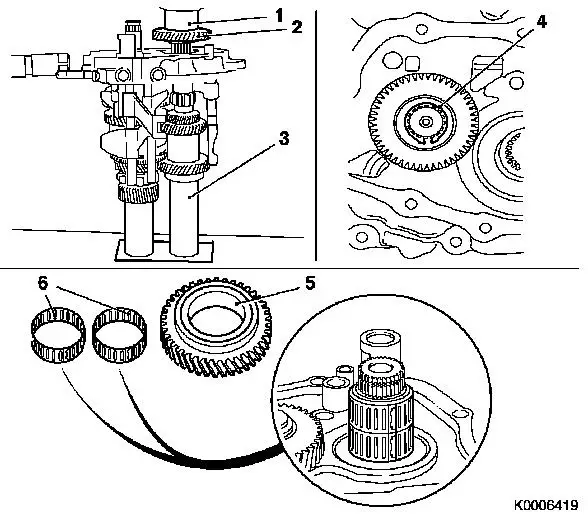

Important: Collect main shaft,

drive shaft and reverse idler.

|

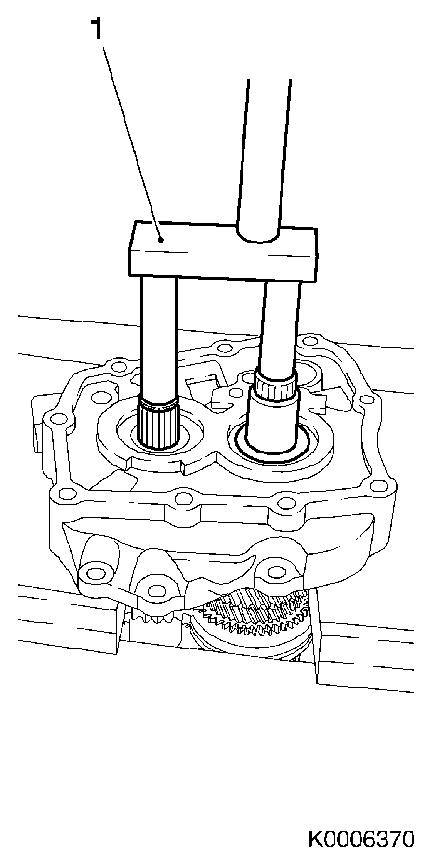

| 17. |

Remove main shaft and drive shaft

| • |

Detach end shield from KM-552

|

| • |

Press main shaft and drive shaft out as shown using KM-6335 (1)

Note: To ensure that

both shafts are pushed out evenly, press harder on the main shaft

side. Take care that the 1st gear wheel is not in contact with the

press.

|

| • |

Collect main shaft, drive shaft and reverse idler

|

|

|

|

|

Important: Note that retaining

ball is released.

|

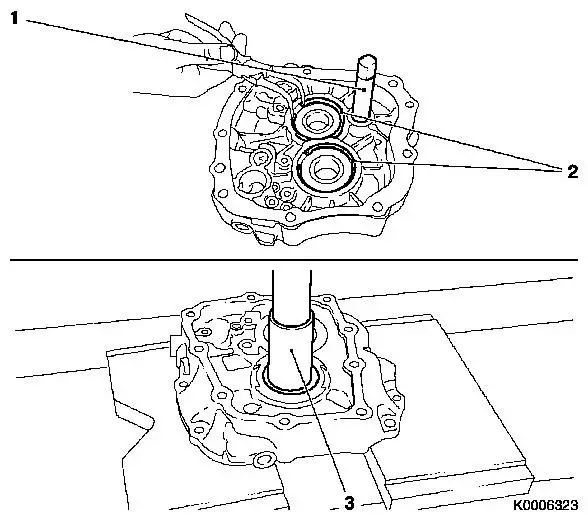

| 18. |

Remove reverse gear axle (1)

| • |

Clamp reverse gear in vice with protective jaws

|

| • |

Carefully knock off end shield with brass punch

|

|

| 19. |

Remove bearing for main and drive shafts

| • |

Remove 2x retaining rings (2)

|

| • |

Press out 2x bearings using KM-500-5

(3)

|

|

|

| 20. |

Clean all parts and sealing surfaces

|

| 21. |

Check parts

| • |

Check parts for wear, signs of scoring, damage - if necessary

replace

|

|

Install

Install

|

Important: Lubricate rotating

parts on their bearing, running, seating, and pressure surfaces

using transmission fluid.

|

| 22. |

Install bearing for main and drive shafts

| • |

Press in 2x bearings using KM-523-1

(1) and KM-6336 (2)

|

| • |

Fit 2x retaining rings (3)

Note: Check retaining

ring for proper seating.

|

|

|

|

Important: Check shaft for proper

seating.

|

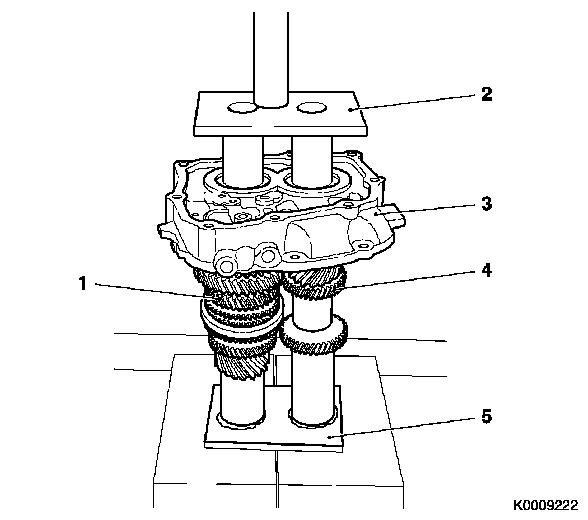

| 23. |

Fit main and drive shafts

| • |

Place main shaft (1) and drive shaft (4) on KM-6337 (5)

|

| • |

Place end shield (3) on main shaft and drive shaft and press on

with KM-6338 (2)

|

|

|

|

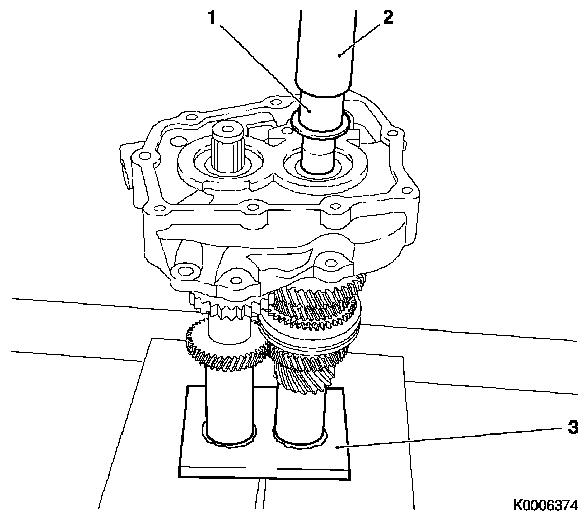

| 24. |

Fit 5th gear bearing sleeve (1)

| • |

Locate end shield on KM-6337 (3)

|

| • |

Press bearing sleeve on main shaft using KM-6339 (2)

|

|

|

|

Important: Note installation

position.

|

| 25. |

Fit reverse gear axle (1)

| • |

Locate reverse idler on axle

Note: Note installation

position, shift fork groove to top.

|

| • |

Press reverse gear axle with inserted lock ball (arrow) to stop

in end shield

|

|

|

|

| 26. |

Attach end shield to KM-113-2

| • |

Attach end shield to KM-552

|

| • |

Attach end shield to KM-113-2 using

KM-552

|

|

| 27. |

Fit locking pin (1)

| • |

Insert 3rd/4th gear and reverse gear locking pins

|

|

Important: To relieve pressure on

shift rod guides in end shield, support shift rods with wooden

wedge when securing with pin.

|

| 28. |

Fit reverse gear shift fork

| • |

Insert reverse gear shift fork (5) and shifter rod (6)

|

| • |

Insert new roll pin using KM-308

(4)

Note: Allow new roll

pin to protrude approximately 2 mm/0.08 in (Dimension I).

|

|

Important: To relieve pressure on

shift rod guides in end shield, support shift rods with wooden

wedge when securing with pin.

|

| 29. |

Fit 1st/2nd gear shift fork

| • |

Insert 1st/2nd gear shift fork (3) and shift rod (2)

|

| • |

Insert new roll pin using KM-308

(4)

Note: Allow new roll

pin to protrude approximately 2 mm/0.08 in (Dimension I).

|

|

|

|

| 30. |

Insert 5th gear (4) shift driver.

|

Important: To relieve pressure on

shift rod guides in end shield, support shift rods with wooden

wedge when securing with pin.

|

| 31. |

Fit 3rd/4th gear shift fork

| • |

Insert 3rd/4th gear shift fork (2) and shift rod (1)

|

| • |

Insert new roll pin using KM-308

(3)

Note: Allow roll pin to

protrude approximately 2 mm.

|

|

| 32. |

Fit locking plugs

| • |

Fit 4x locking plugs (5, 6 and (7)

Note: Drive to stop

with plastic hammer or soft metal drift.

|

|

| 33. |

Bring gear shift fork into neutral speed position

|

|

|

| 34. |

Engage 2nd, 3rd and 5th gear

Note: Turn end shield

onto its side

|

| 35. |

Fit bridge for lock pin

| • |

Insert bridge for lock pins (2) in end shield, during this

bring the gear shift forks into neutral position

|

|

| 36. |

Attach bearing support (4) with pawl (3)

| • |

Insert 2x bolts (arrow) with locking compound

|

| • |

Tighten 2x bolt - tightening torque 7

Nm

|

|

|

|

Important: Note installation

direction. Long gear hub points to end shield.

|

| 37. |

Install 5th gear (driven) (2)

| • |

Insert end shield with main and drive shafts in KM-6337 (3)

|

| • |

Press on 5th gear using KM-473

(1)

|

| • |

fit new retaining ring (4)

Note: Retaining ring

must engage completely.

|

|

| 38. |

Fit 5th gear (5) (driven)

| • |

Coat needle bearings (6) with transmission fluid and place on

main shaft

Note: Ensure correct

seating of slotted needle bearings.

|

| • |

Locate 5th gear and 5th gear synchroniser ring on main

shaft

|

|

|

|

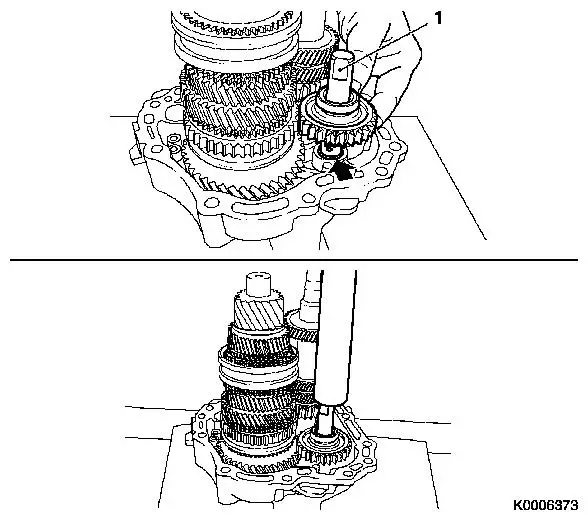

| 39. |

Press on 5th gear synchromesh body assembly

| • |

Insert end shield in KM-6337

|

| • |

Place synchromesh body assembly (1) on main shaft

|

Important: Synchroniser ring lugs

must be aligned with synchromesh body grooves.

|

| • |

Press synchro body in KM-473 on to

main shaft

|

| • |

fit new retaining ring (2)

Note: Retaining ring

must engage completely.

|

|

| 40. |

Fit bearing support with rocker arm

| • |

Insert 2x crosshead shoes (arrow) in 5th gear shift fork

(3)

|

| • |

Insert bearing support with rocker arm in end shield

|

| • |

Insert 2x bolts with locking compound

|

| • |

Tighten 2x bolt - tightening torque 22

Nm .

|

|

|

|

| 41. |

Install friction washer and magnet

| • |

Fit friction washer (arrow) on axle, reverse gear wheel, with

grease

|

| • |

Insert magnet with grease

|

|

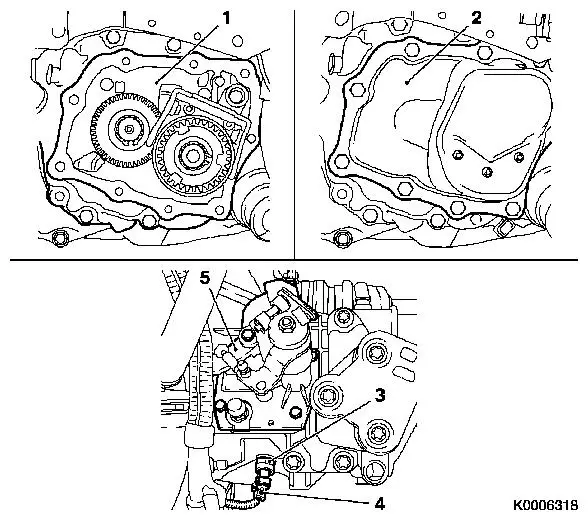

Important: Before installing end

shield, check following items for position and seating:

| 1. |

3rd/4th gear shift fork |

| 2. |

3rd/4th gear shift rod |

| 3. |

5th gear shift driver |

| 4. |

1st/2nd gear shift rod |

| 5. |

1st/2nd gear shift fork |

| 6. |

Lock pin for gear stop |

| 7. |

Reverse gear shift fork |

| 8. |

Reverse gear shift rod |

|

| 42. |

Detach end shield from KM-113-2

| • |

Detach end shield from KM-552

|

|

|

|

| 43. |

Install end shield (1)

Note: Note magnet.

| • |

See operation "Gasket for End Shield, Replace

(F13/F17/F17+/F18)".

|

|

| 44. |

Fit end shield (2) cover

| • |

See operation "Gasket for End Shield Cover, Replace

(F13/F17/F17+/F18)".

|

|

| 45. |

Fit gearshift cover (5)

| • |

see operation "Gearshift Cover, Remove and Install and/or Seal

(F13/F17/F17+/F18)"

|

|

| 46. |

Transmission Fluid Level, Check and Correct

| • |

see operation "Transmission Fluid, Check and Correct

(F13/F17/F17+/F18)"

|

|

| 47. |

Fit reversing lamp switch (3)

| • |

insert with new seal ring

|

| • |

Tighten switch for reversing lamp firmly - tightening torque

20 Nm .

|

| • |

Connect wiring harness plug (4)

|

|

| 48. |

Check gearshift

| • |

Check ease of gear shifting with vehicle standing, engine

running and clutch disengaged.

|

|

|

|