|

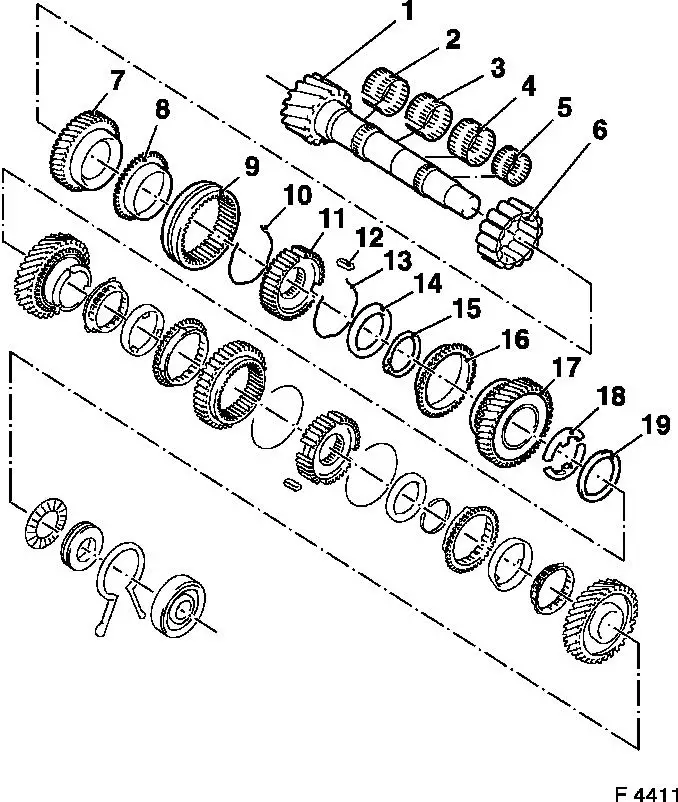

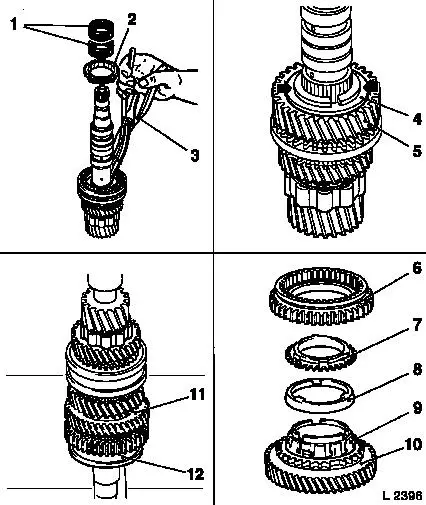

Main Shaft, Dismantle and Assemble (F18)

Illustration

| 1. |

Main shaft |

| 2. |

4th gear needle bearing |

| 3. |

3rd gear needle bearing |

| 4. |

2nd gear needle bearing |

| 5. |

1st gear needle bearing |

| 6. |

Roller bearing inner ring |

| 7. |

4th gear |

| 8. |

Synchroniser ring |

| 9. |

Shift sleeve |

| 10. |

Synchroniser spring |

| 11. |

Synchromesh body |

| 12. |

Sliding block |

| 13. |

Synchroniser spring |

| 14. |

Thrust washer |

| 15. |

Retaining ring |

| 16. |

Synchroniser ring |

| 17. |

3rd gear |

| 18. |

Thrust washer halves |

| 19. |

Retaining ring |

|

|

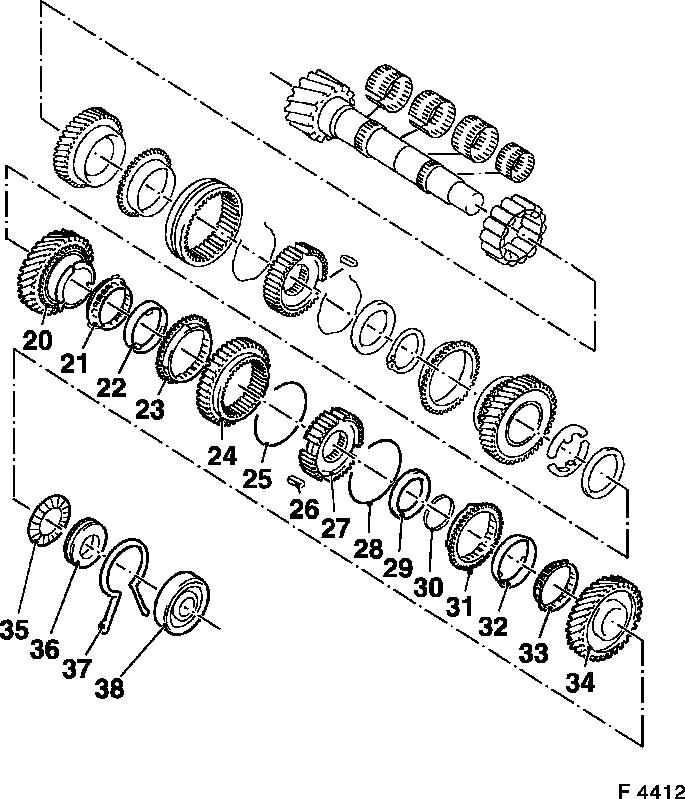

Illustration: Main Shaft

|

20

|

2nd gear

|

|

21

|

Inner synchroniser ring

|

|

22

|

Intermediate ring

|

|

23

|

Outer synchroniser ring

|

|

24

|

Shift sleeve

|

|

25

|

Synchroniser spring

|

|

26

|

Sliding block

|

|

27

|

Synchromesh body

|

|

28

|

Synchroniser spring

|

|

29

|

Thrust washer

|

|

30

|

Retaining ring

|

|

31

|

Outer synchroniser ring

|

|

32

|

Intermediate ring

|

|

33

|

Inner synchroniser ring

|

|

34

|

1st gear

|

|

35

|

Axial needle bearing

|

|

36

|

Spacer washer

|

|

37

|

Retaining ring

|

|

38

|

Ball bearing

|

|

|

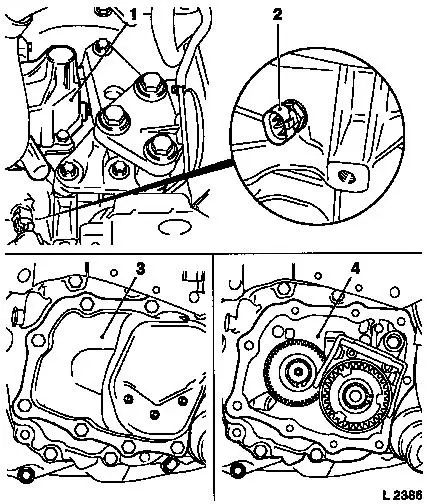

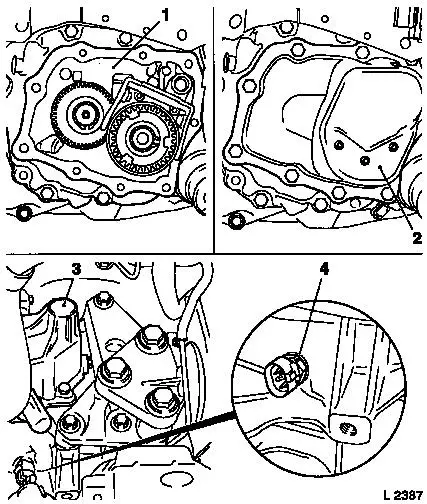

Note: Transmission

remains installed.

Remove Remove

|

Remove gearshift cover (1) – see operation "Gearshift

Cover, Remove and Install and/or Seal (F13/F17/F17+/F18)".

Remove reversing lamps switch (2).

Remove end shield cover (3) – see operation "Gasket for

End Shield Cover, Replace (F13/F17/F17+/F18)".

Remove end shield (4) from transmission – see operation

"Gasket for End Shield, Replace (F13/F17/F17+/F18)".

|

|

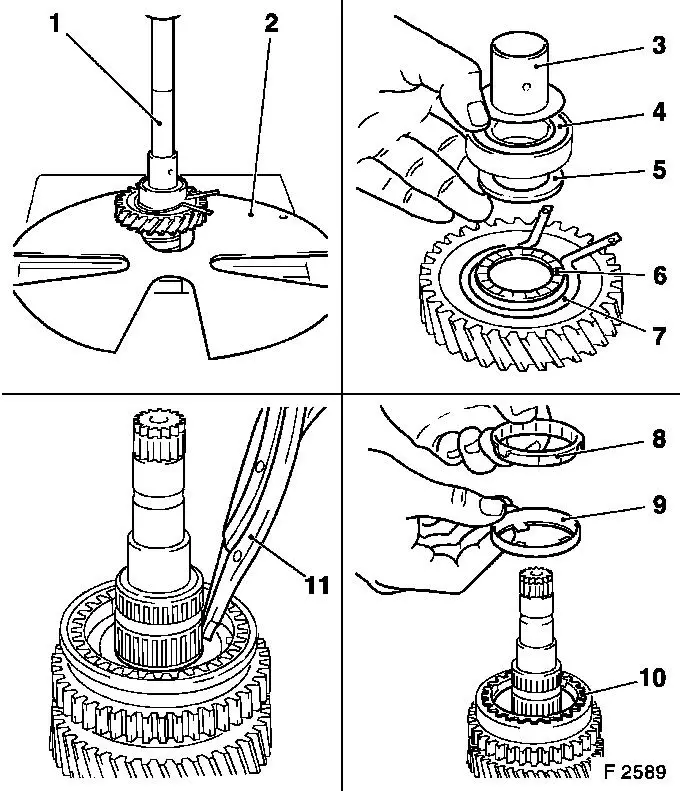

Remove Remove

Remove main shaft – see operation "End Shield, Dismantle

and Assemble (F18)".

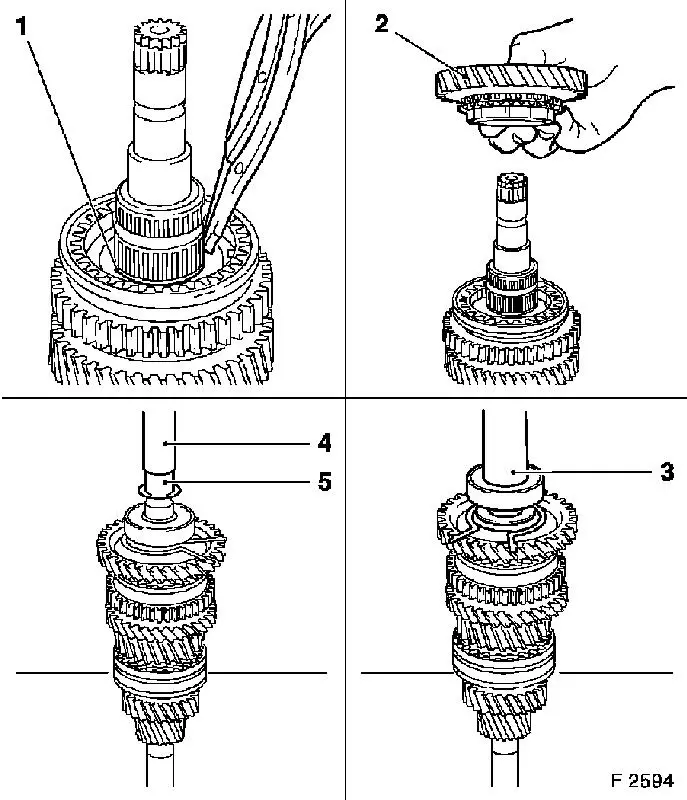

Disassemble

Disassemble

|

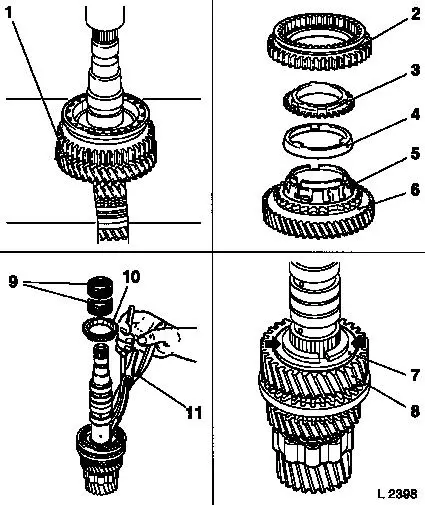

Press 1st gear from main shaft with KM-307-B (2) and KM-736

(1).

Remove sleeve (3), ball bearing (4), pressure washer (5), output

shaft (6) and retaining ring (7).

Remove synchroniser rings for 1st gear, consisting of inner

synchroniser ring (8) outer synchroniser ring (10) and intermediate

ring (9).

Remove retaining ring for 1st/2nd gear synchromesh body with

KM-396 (11).

|

|

Disassemble

Disassemble

|

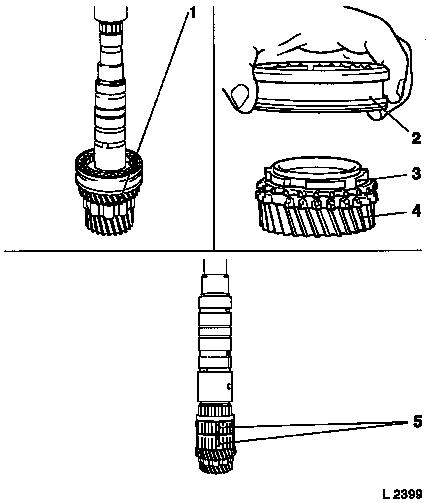

Press 1st/2nd gear synchromesh body assembly and 2nd gear (1)

from main shaft – supporting 2nd gear on recesses of press

support plates.

Remove 1st/2nd gear synchromesh body assembly (2) and 2nd gear

synchroniser ring (6) – detach outer synchroniser ring (3),

intermediate ring (4) and inner synchroniser ring (5).

Remove retaining ring (7) for thrust washer and both thrust

washer halves (arrow) from main shaft.

Detach 3rd gear (8).

Detach slotted needle bearing (9) and 3rd gear synchroniser ring

(10). Remove retaining ring for 3rd/4th gear synchromesh body with

KM-396 (11) – remove spacing ring located underneath from

synchromesh body.

|

|

Disassemble

Disassemble

|

Press 3rd/4th gear synchromesh body assembly from main shaft

– supporting 4th gear (4) on recesses of press support

plates.

Remove 3rd/4th gear synchromesh body assembly (2) and 4th gear

synchroniser ring (3) from 4th gear. Detached slotted needle

bearing (5) from main shaft.

Clean Clean

Clean all parts.

Inspect

Inspect

Check removed parts for damage and wear.

|

|

Note: Coat all parts

with transmission fluid before assembly.

Check parts for wear, signs of scoring, damage; if necessary

replace.

Caution

Always check the gearwheels on the gear cluster for damage to

the gearwheels and replace gear cluster if necessary.

Note: If a

synchromesh body assembly has been completely dismantled then the

following method of procedure shall be observed for assembly.

Assemble

Assemble

|

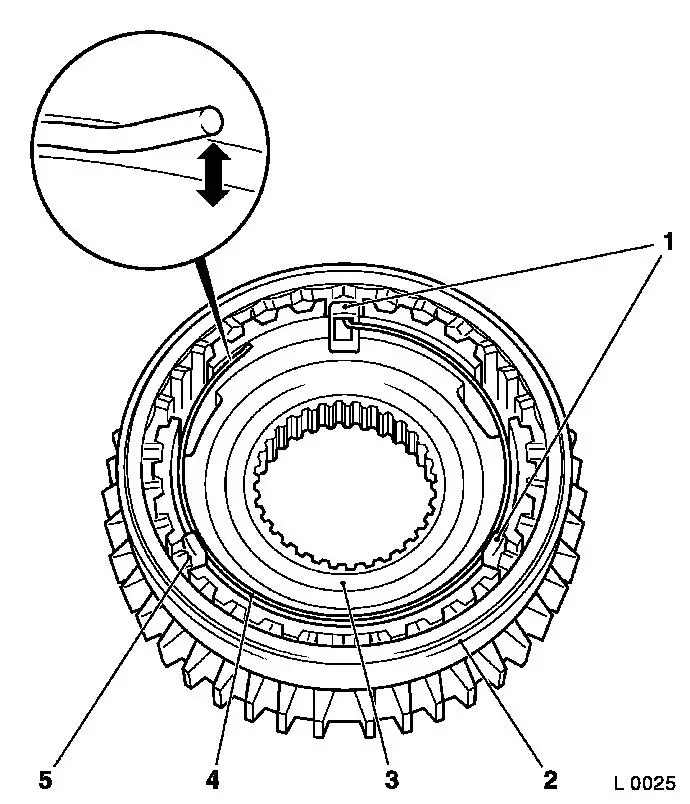

Insert synchromesh body (3) into shifter collar (2). Insert

slide blocks (1 and 5) with the open end toward synchromesh

body.

Insert synchroniser spring (4); ensure that the correct end of

synchromesh body raises (arrow) for correct installation

position.

If this is not the case, turn synchroniser spring 180° and

reinstall.

Offset end of synchroniser engages in a slide block.

|

|

Assemble

Assemble

|

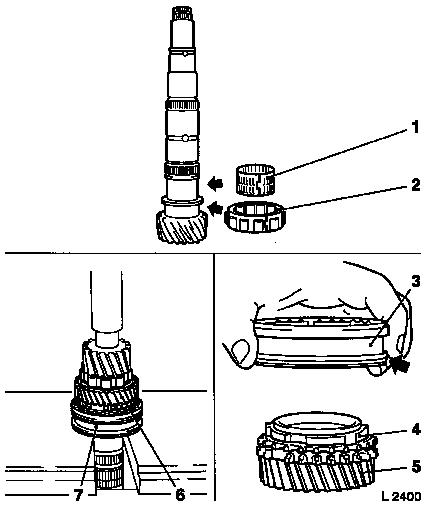

Push slotted roller bearing (2) onto main shaft, it must audibly

engage on locking. Push double-row, slotted needle bearing (1) onto

main shaft. Position 4th gear synchroniser ring (4) and synchromesh

body assembly (3) on 4th gear (5).

Caution

Side of slider sleeve with groove (arrow) points to 4th

gear.

Assemble

Assemble

Press 3rd/ 4th gear synchromesh body assembly (7) with

synchroniser ring and 4th gear (6) onto main shaft – ensure

that lugs in synchroniser ring align with grooves in synchromesh

body.

|

|

Assemble

Assemble

|

Place spacer ring on synchromesh body and attach new retaining

ring with KM-396 (3) – ensure that the synchroniser ring is

correctly seated in the groove. Attach 3rd gear synchroniser ring

(2) to synchromesh body assembly and attach slotted needle bearing

(1) to main shaft. Position 3rd gear (5) on main shaft.

Mount both halves of thrust washer (arrows) and retaining ring

(4).

Attach synchroniser rings and synchromesh body assembly (6) onto

2nd gear (10) – outer synchroniser ring (9), intermediate

ring (8) and inner synchroniser ring (7).

Press 1st/2nd gear synchromesh body assembly (12) with 2nd gear

(11) onto main shaft so that lugs of outer synchroniser ring align

with grooves in synchromesh body.

|

|

Assemble

Assemble

|

Insert retaining ring (1) for 1st/2nd gear synchromesh body with

KM-396.

Place 1st gear (2) with synchroniser ring (inner synchroniser

ring, intermediate ring and outer synchroniser ring) on 1st/2nd

gear assembly – ensure that lugs in outer synchroniser ring

align with grooves in synchromesh body.

Attach new retaining ring, output shaft and pressure washer onto

1st gear. Press ball bearing with KM-258 (3) onto main shaft.

Press sleeve (5) onto main shaft with KM-258 (4).

|

|

Inspect

Inspect

All gears must easily be turned.

Install main shaft – see operation "End Shield with Main

and Drive Shaft, Dismantle and Assemble (F18)".

Install

Install

|

Insert end shield (1) into transmission – see operation

"Gasket for End Shield, Replace – F13/F17/F17+/F18".

Install gasket for end shield cover (2) – see operation

"Gasket for End Shield Cover, Replace –

F13/F17/F17+/F18".

Install reversing lamps switch (4) with new seal ring –

tightening torque 20 Nm / 15 lbf. ft.

Install gearshift cover (3) – see operation "Gearshift

Cover, Remove and Install and/or Seal (F13/F17/F17+/F18)".

|

|

Inspect

Inspect

Check transmission fluid level – see operation

"Transmission Fluid Level, Check and Correct

(F13/F17/F17+/F18)".

|