|

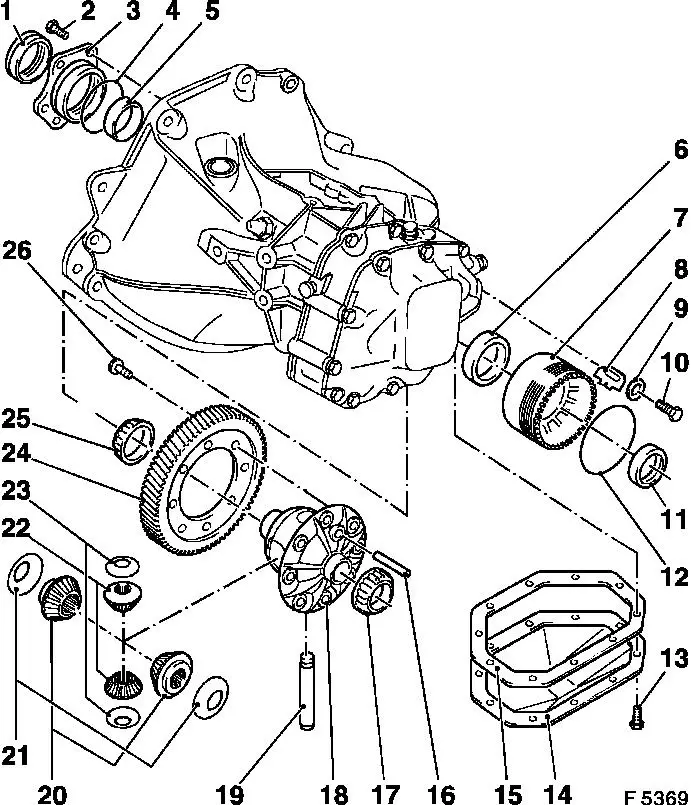

Differential, Dismantle and Assemble (F18)

|

1

|

Axle shaft seal ring

|

|

2

|

Fastening bolt

|

|

3

|

Bearing flange

|

|

4

|

O-ring

|

|

5

|

Outer race of tapered roller bearing

|

|

6

|

Outer race of tapered roller bearing

|

|

7

|

Bearing ring

|

|

8

|

Lock tab

|

|

9

|

Spring washer

|

|

10

|

Fastening bolt

|

|

11

|

Axle shaft seal ring

|

|

12

|

O-ring

|

|

13

|

Fastening bolt

|

|

|

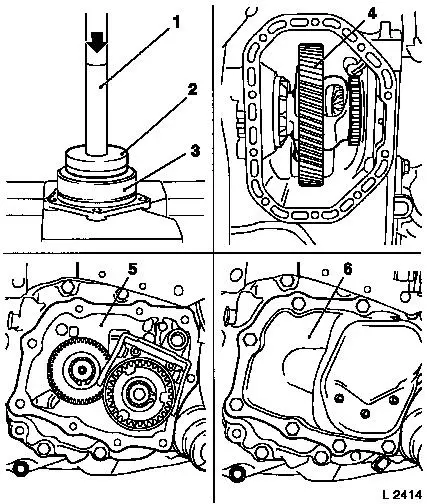

Illustration, Differential (F18)

|

14

|

Differential cover

|

|

15

|

Gasket

|

|

16

|

Retaining pin

|

|

17

|

Inner race of tapered roller bearing

|

|

18

|

Differential housing

|

|

19

|

Differential housing axle

|

|

20

|

Axle shaft bevel gears

|

|

21

|

Thrust washer

|

|

22

|

Differential bevel gears

|

|

23

|

Thrust washer

|

|

24

|

Ring gear

|

|

25

|

Inner race of tapered roller bearing

|

|

26

|

Fastening bolt

|

|

|

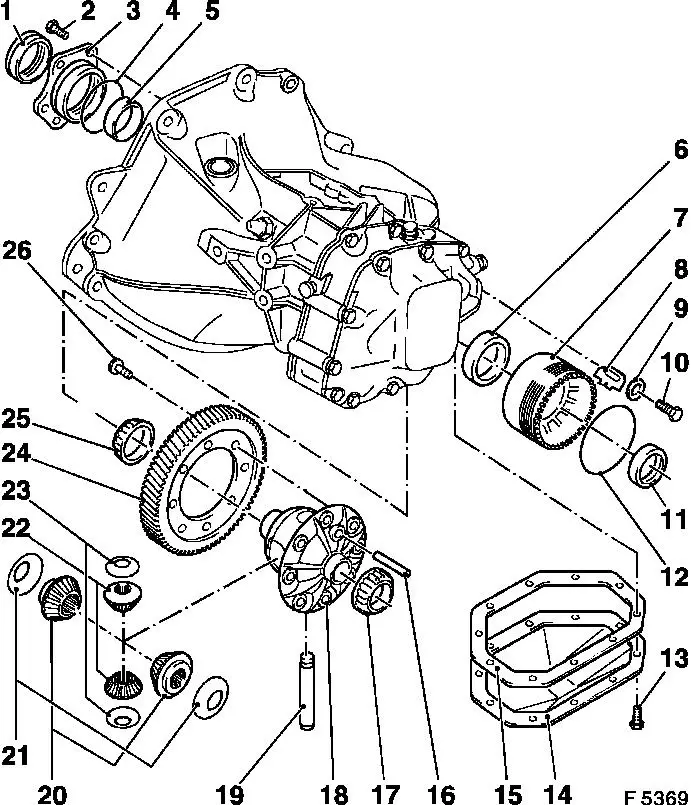

Note: Transmission

remains installed.

Remove Remove

|

Remove axle shafts (1) – see operation "Axle Shafts,

Remove and Install" in group "E".

Remove end shield cover (2) – see operation "Gasket for

End Shield Cover, Replace – F13/F17/F17+/F18".

Remove end shield (3) from transmission housing – see

operation "Gasket for End Shield, Replace (F13/F17/F17+/F18)".

Remove differential (4) – see operation "Differential,

Remove and Install (F18)".

|

|

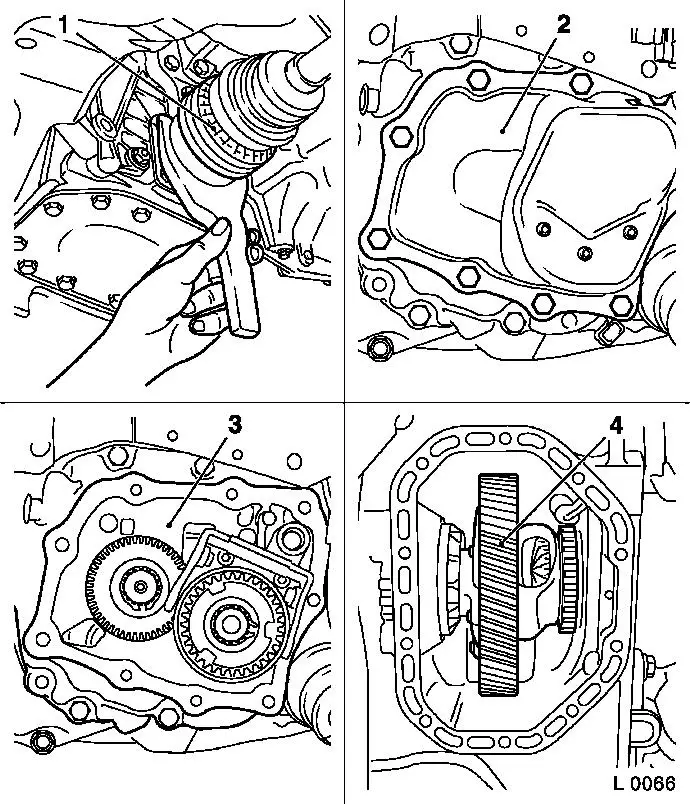

Disassemble

Disassemble

|

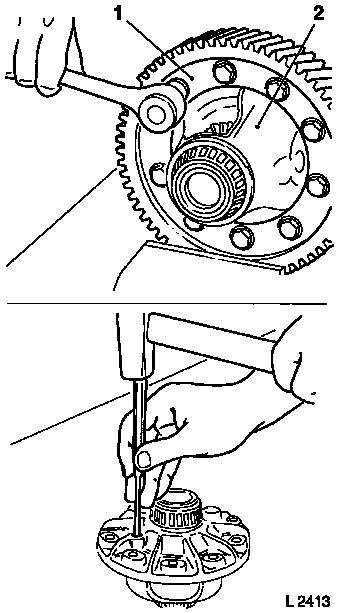

Remove seal rings from bearing ring (3) and transmission using

KM-454-2 (1) and KM-454-4 (2).

Only necessary for replacement: drive outer race for tapered

roller bearing out of bearing ring with KM-304 (4), KM-451 (5),

place KM-502-A underneath.

Drive outer race for tapered roller bearing out of bearing

flange with KM-304 (7), KM-451 (8), place KM-502-A underneath.

|

|

Remove Remove

|

Remove drive gear fastening bolt (1) from differential housing

(2).

Knock drive gear from differential housing with brass drift.

Caution

Always replace drive gears (driving drive gear with main shaft)

in pairs. Note identification groove running around tip of

tooth.

Note: Following

illustrations show further dismantling without replacement of

tapered roller bearing inner races.

Remove Remove

Drive out locking pin of bevel gear axle. Press bevel gear axle

out of differential housing.

|

|

Remove Remove

|

Screw out differential bevel pinion with friction washer. Remove

axle drive bevel gear with friction washer.

Disassemble

Disassemble

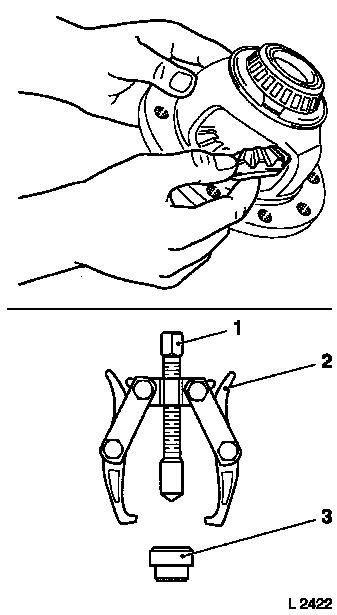

Only necessary for replacement: pull off both tapered roller

bearing inner races with KM-161-B (1), KM-161-3 (2) and KM-161-4

(3).

Note: When re-using

the tapered roller bearing, the respective outer and inner races

must not be swapped over. For overhaul operations, the speedometer

gear (driving) should be destroyed, if still present. On assembly

it is not re-installed.

Inspect

Inspect

Removed parts for wear, signs of scoring, damage, hairline

cracks; if necessary replace.

|

|

Note: Lubricate

rotating parts on their bearing, running, seating, and pressure

surfaces using transmission fluid.

Assemble

Assemble

Insert axle drive bevel gear with friction washer in

differential housing.

|

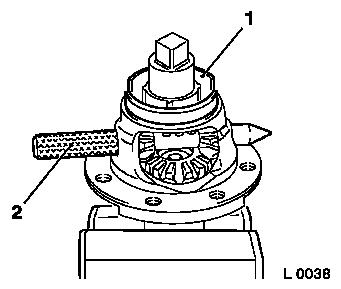

Screw in differential bevel pinions with friction washer into

differential housing (1) and centre with KM-160-4 (2).

Pull out KM-160-4 and insert bevel gear shaft into differential

housing. Drive in locking pin and secure through centre

punching.

|

|

Adjust Adjust

Pre-tension of axle shaft bevel gears.

Measure breakaway torque for installation free of play (no

backlash) – KM-995-A, MKM-536-A. Nominal value: 8 to 15 Nm /

6 to 11 lbf. ft. For excessively high breakaway torques use thinner

adjusting washer. For excessively low breakaway torques use thicker

adjusting washers.

Available washer thicknesses: 0.82 mm, 0.88 mm, 0.94 mm.

After adjustment is completed: Drive in locking pin and secure

by centre punching at bore edge.

Install

Install

Clamp differential housing in vice, KM-524-A.

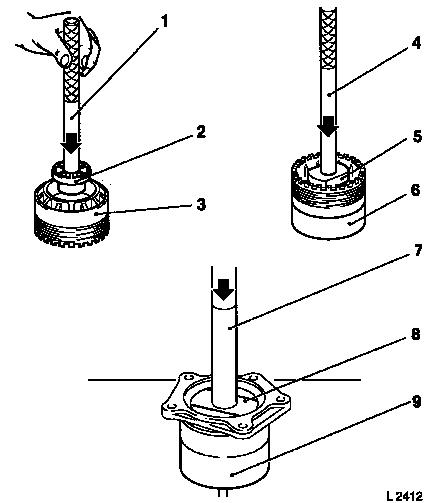

Assemble

Assemble

|

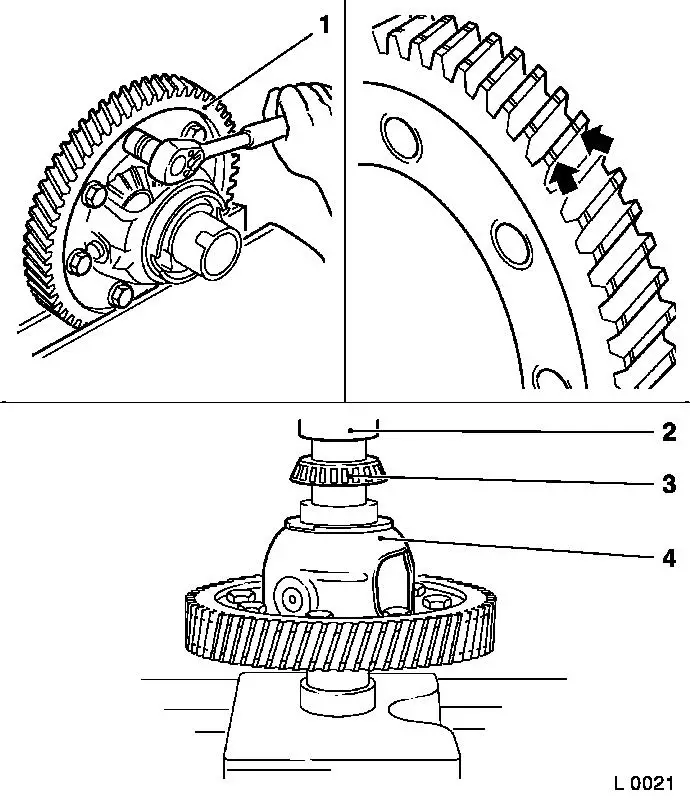

Attach drive gear (1) with new fastening bolts to differential

housing – tightening torque 70 Nm / 52 lbf. ft. +

45°.

Note: Replace drive

gears only in pairs (driving and driven). Note identification

groove (arrows) running around tip of tooth.

Assemble

Assemble

Press tapered roller bearing inner races (3) onto differential

housing (4) with KM-522 (2).

Install respective outer race for tapered roller bearing in

transmission or bearing ring – use KM-305 and KM-451. Stop

outer race for tapered roller bearing lightly in housing.

|

|

Install

Install

|

Press respective outer race for tapered roller bearing into

bearing flange (3) or bearing ring to the stop, KM-305 (1) and

KM-451 (2).

Drive new axle shaft seal ring into bearing flange and bearing

ring with KM-519 – see operation "Axle Shaft Seal Ring,

Replace (F13/F17/F17+/F18)".

Install differential (4) – see operation "Differential,

Remove and Install (F18)".

Install end shield (5) – see operation "Gasket for End

Shield, Replace – F13/F17/F17+/F18".

Install end shield cover (6) – see operation "Gasket for

End Shield Cover, Replace (F13/F17/F17+/F18)".

Install axle shafts – see operation "Axle Shafts, Remove

and Install" in group "E".

|

|

|