|

Recommend equipment for MIG brazing

Note: If applicable,

also note the recommendations for MIG inert gas brazing equipment

in the TIS Newsletter!

Important:

Opel/Vauxhall recommends the use of MIG brazing equipment specified

in the list below.

Important: In

order to maintain high quality, only use Opel/Vauxhall-approved MIG

brazing wiring CuSi3 as the parameter settings of the gas-shielded

MIG brazing equipment are affected if other brazing wire is

used.

Observe the following when MIG

brazing.

- Only the machines specified below from the relevant

manufacturer are recommended by Opel/Vauxhall for bodywork

repair.

- Only the machines specified below are pre-programmed with

special welding programs/parameter settings/parameter documentation

for Opel/Vauxhall vehicles.

- Only the machines specified below have specific welding

programs/parameter settings for each new Opel/Vauxhall vehicle

model.

- The following brazing wire and shielding gas are to be used for

gas-shielded MIG brazing:

- Brazing wire CuSi3, reel D200 with 5 kg, obtained via EPC, part

no. 93 180 983, cat. no. 19 72 004

- Argon shielding gas (quality 4.6 or higher)

Recommended MIG welders (version February

2008)

Note: All of the

recommended machines listed below are purchased directly from the

manufacturer. Please contact the manufacturer at the address

specified below to find a representative in your area.

Note: A reel adapter

for reel D200 and basket reel K300 can be obtained directly from

the manufacturer.

|

1.

|

CLOOS

|

| |

Carl Cloos Schweißtechnik GmbH

|

| |

Industriestraße

|

| |

D-35708 Haiger

|

| |

Germany

|

| |

www.cloos.de

|

| |

The following product(s) fulfil the requirements:

|

| |

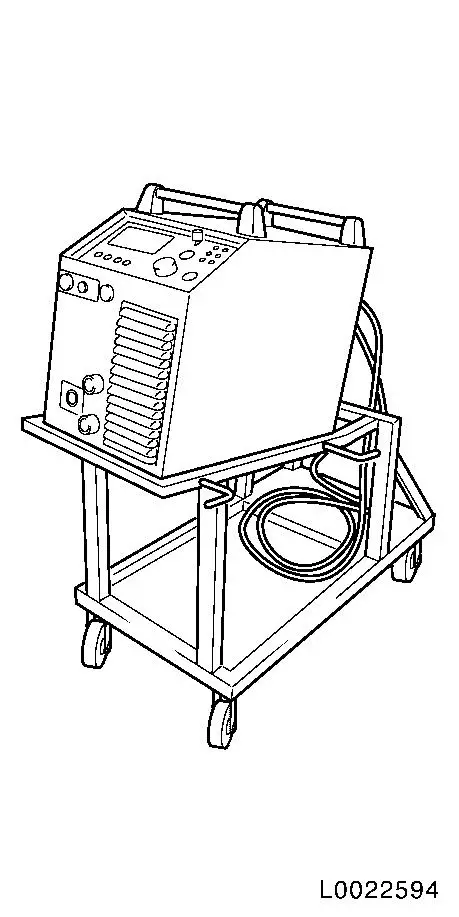

1.1.

|

GLC 353 MC3 with CK 98 A

|

| |

1.2.

|

GLC 303 MC4

|

| |

Reference number:

|

| |

1.1.

|

OP 510402

|

| |

1.2.

|

OP 88-08-03

|

|

|

|

Note: GLC 353 MC3 has

been replaced by GLC MC4.

|

|

|

2.

|

ELMATech (previously DALEX)

|

| |

ELMATech AG

|

| |

Plant 2

|

| |

Wisseraue 1

|

| |

D-51597 Morsbach

|

| |

Germany

|

| |

www.elmatech-ag.com

|

| |

The following product fulfils the requirements:

|

| |

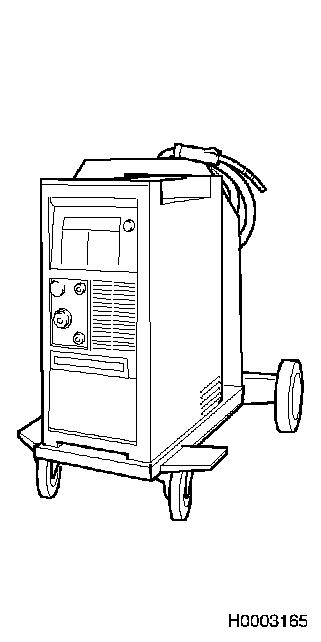

2.1.

|

MIDI – MIG 300/800

|

| |

Reference number:

|

| |

2.1.

|

SA.20268.1

|

|

|

|

2.2

|

Stanners Equipment Ltd.

|

| |

Stanners Equipment Ltd.

|

| |

Coopies Lane Industrial Estate

|

| |

Morpeth

|

| |

Northhumberland

|

| |

NE61 6JN

|

| |

United Kingdom

|

| |

www.stanners-equipment.co.uk

|

| |

The following product fulfils the requirement:

|

| |

2.2.

|

MIG 300/800 PG

|

|

|

|

3.

|

FRONIUS

|

| |

Fronius International GmbH

|

| |

Buxbaumstraße 2

|

| |

A-4600 Wels

|

| |

Austria

|

| |

www.fronius.com

|

| |

The following product fulfils the requirements:

|

| |

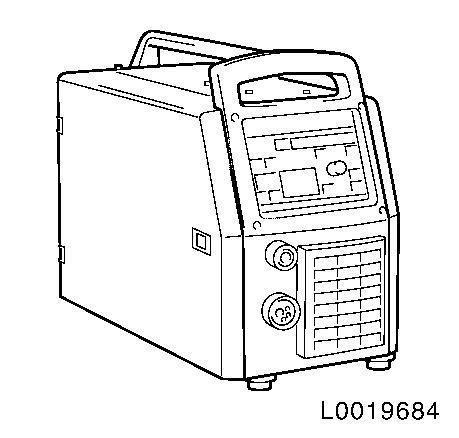

3.1.

|

TPS2700 4R/E

|

| |

Reference number:

|

| |

3.1.

|

EXP 1.2.009

|

|

|

|

4.

|

KEMPPI

|

| |

Kemppi GmbH

|

| |

Otto-Hahn-Straße 14

|

| |

D-35510 Butzbach

|

| |

Germany

|

| |

www.kemppi.com

|

| |

The following products fulfil the requirements:

|

| |

4.1.

|

Pro 3200 EVO with Promig 530 including MXE panel

|

| |

4.2.

|

Kempact TM Pulse 2800 Automotive

|

| |

Reference number:

|

| |

4.1.

|

PROMIG 3200 OPEL

|

| |

4.2.

|

KPACT2800AUTO

|

|

|

|

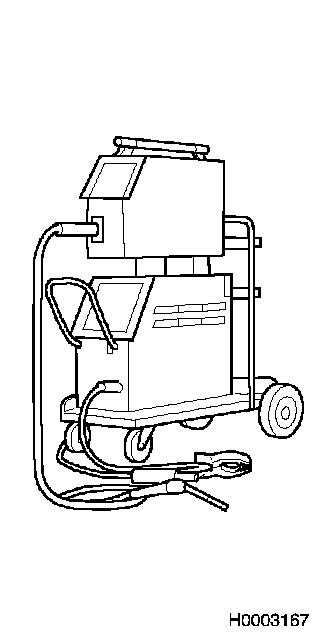

5.1

|

MIGATRONIC

|

| |

Migatronic Schweißmaschinen GmbH

|

| |

Sansusweg 12

|

| |

D-35435 Wettenberg

|

| |

Germany

|

| |

www.migatronic.com

|

| |

The following product fulfils the requirements:

|

| |

5.1.

|

Flex 330 XMI-L, No.: 79541063 Version GM

|

| |

|

Flex 3000 C-L, No.: 79541317 Version GM

|

| |

|

Flex 3000 C-L Duo, No.: 79541330 Version GM

|

|

|

|

5.2

|

Stanners Equipment Ltd.

|

| |

Stanners Equipment Ltd.

|

| |

Coopies Lane Industrial Estate

|

| |

Morpeth

|

| |

Northhumberland

|

| |

NE61 6JN

|

| |

United Kingdom

|

| |

www.stanners-equipment.co.uk

|

| |

The following product fulfils the requirement:

|

| |

5.2.

|

AS3000 Synergic MIG / MAG Welder

|

| |

Reference number:

|

| |

5.2.

|

AS3000

|

| |

|

No longer in production, for replacement see

2.2

|

|

6.

|

WIELÄNDER & SCHILL

|

| |

Wieländer & Schill

|

| |

Siederstraße 50

|

| |

D-78054 Villingen-Schwennigen

|

| |

Germany

|

| |

www.wielanderschill.com

|

| |

The following product fulfils the requirements:

|

| |

6.1.

|

InvertaPuls IP 10 Digital

|

| |

Reference number:

|

| |

6.1.

|

331010

|

|

|

|

7.

|

FAN

|

| |

FAN spot welding and bodywork technology

|

| |

Laahenerstr. 26

|

| |

A-4600 Wels

|

| |

Austria

|

| |

www.fan-austria.com

|

| |

The following product fulfils the requirements:

|

| |

7.1.

|

Proton AL Puls+ 2500

|

| |

Reference number:

|

| |

7.1.

|

FAN, No.0902

|

|

|

|