Astra H

|

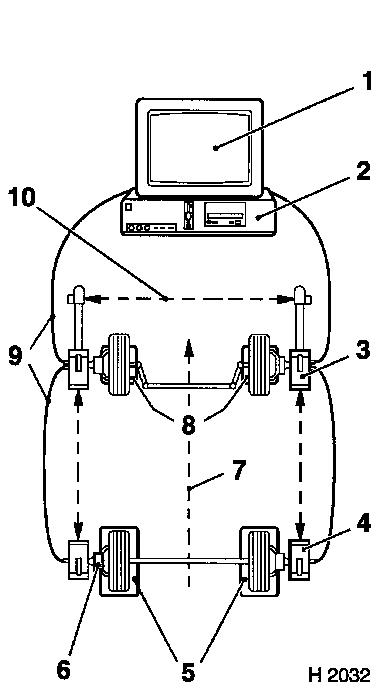

Electronic alignment devices / Suspension alignment computer The state of the art in modern workshops is electronic alignment by computer-supported chassis alignment systems. These are characterised by simple operation, fast measurement procedure, precise determination of measurement values and the possibility of direct nominal/actual comparison. They usually comprise an equipment trolley for the PC, screen and printer, and a holder for the measurement value emitter, wheel adapter and turntables. The nominal values and setting instructions specified by Opel/Vauxhall and stored in the PC, with associated pictures from current service literature, can be updated via diskette or CD Rom drive. An additional CD-ROM drive provides access to the TIS-CD (TIS = TECH Information-System) produced by Opel/Vauxhall which contains the most up-to-date information in the Service Literature. An additional free COM-2 interface may also be used to program the TECH 2 and TECH 31/32 diagnostic devices. A printer may be used to print out both the input and the output measurements with a direct nominal-actual comparison for the customer. The measurement result may be stored in the PC specifically for the customer. As the measurement procedure is stipulated by Opel/Vauxhall and only slight difference can occur in the screen display, computer-supported chassis alignment systems only differ by the method of measurement transmission between the individual emitters. The data is transmitted between the measurement value emitters on wear-free infrared beams, by radio or cable. The rim run-out compensation required by Opel/Vauxhall and for precise chassis alignment is taken into account electronically for the measurement. In addition, the geometric driving axis is automatically determined for the front axle measurement. The accuracy of the measuring sensors is between ± 1 or ± 4 angular minutes depending upon the type of measurement (for example camber or toe)

Advantages:

The individual steps for performance of a complete chassis alignment using computer-supported alignment systems are given in the operating instructions for the alignment computer. |

||||||||||||||||||||||