|

Compression, Check

Important: When

working on the fuel system it is essential to pay attention to

cleanliness as even the smallest dirt particles can lead to faults

in engine operation or in the fuel system. Open fuel connections

must be sealed with appropriate plugs from the Opel Parts Catalogue

(catalogue number: 45 06 154 / part number: 9201697). Sealing plugs

are only intended to be used once.

Remove Remove

| 2. |

Disconnect battery

| • |

Detach ground connection from ground terminal

|

|

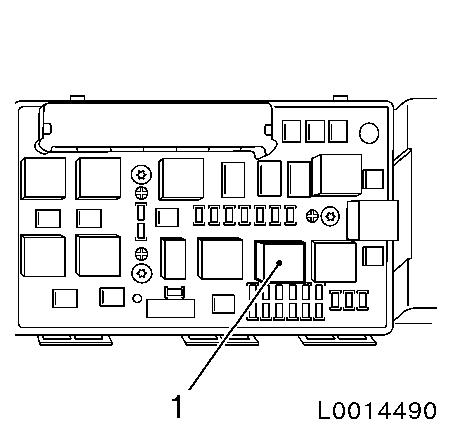

| 4. |

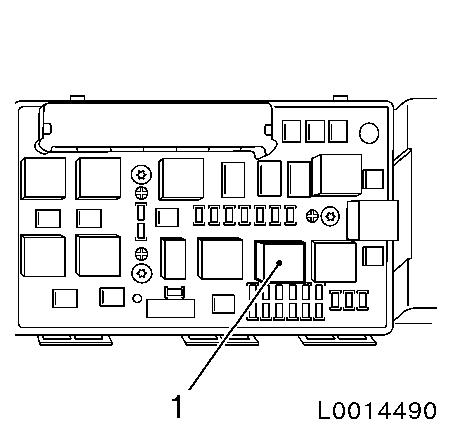

Remove fuel pump relay

| • |

Detach relay holder cover

|

| • |

Attach relay holder cover

|

|

|

|

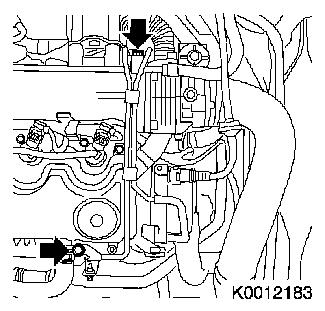

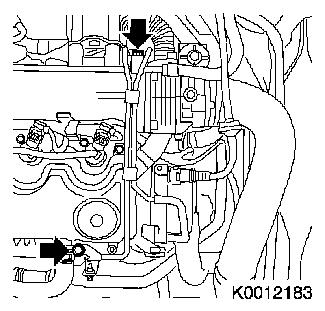

| 5. |

Detach vacuum line

| • |

Unscrew 2x bolts (arrows)

|

| • |

Detach 2x hose vacuum unit to vacuum line

|

|

|

|

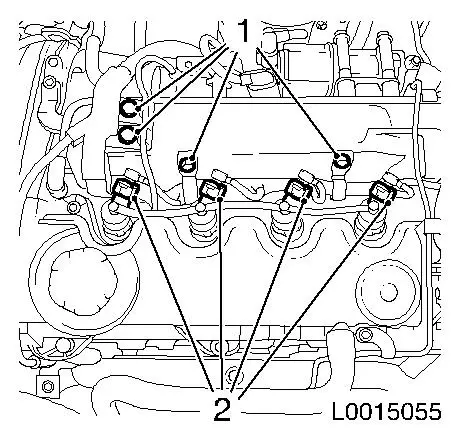

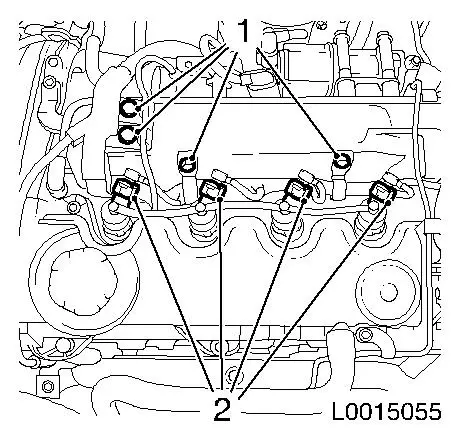

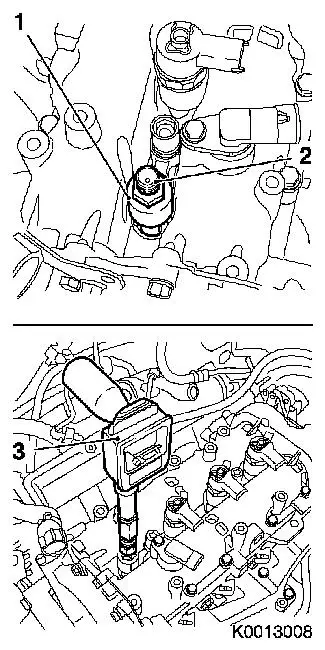

| 6. |

Detach wiring harness

| • |

Disconnect 4x wiring harness plugs for injector (2)

|

|

|

|

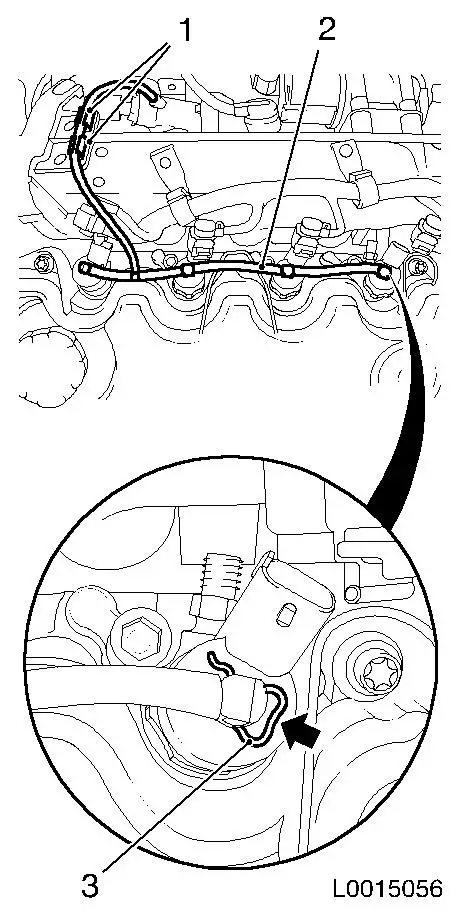

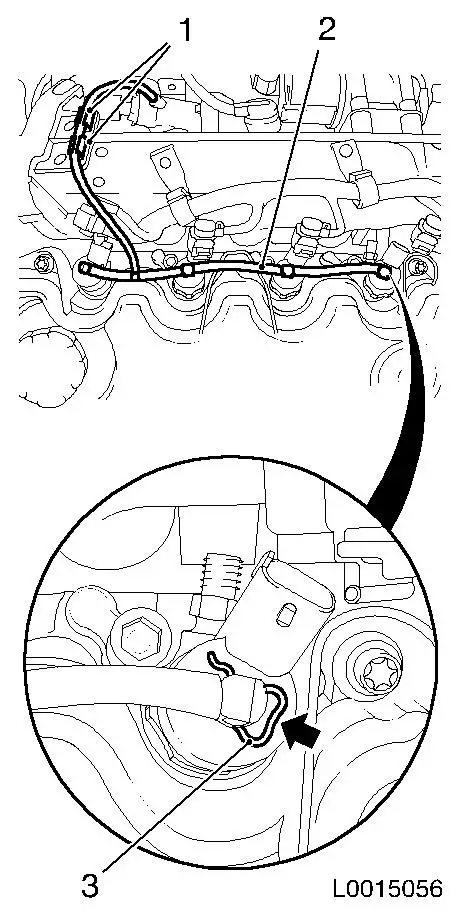

| 7. |

Detach 4x oil leak line (2) from injectors

Note: The oil leak line

must not be detached from the fuel return damping case. It if is

detached, it must be replaced.

| • |

Release 4x retaining clamp (3) from injector in direction of

arrow

| – |

Pull off oil leak line

Note: Close 4x

injectors with suitable

Sealing plug

1)

|

|

| • |

Unclip 2x oil leak line from bracket (1)

|

|

|

|

| 8. |

Detach 4x high pressure line - accumulator to injector

Important: When releasing the

retaining nut, counterhold with open-ended wrench against the

injector

|

| • |

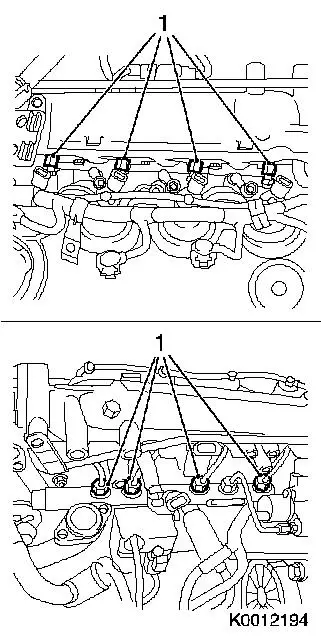

Unscrew 8x union nut (1)

Note: Close opened fuel

connections with appropriate plugs

1)

|

|

|

|

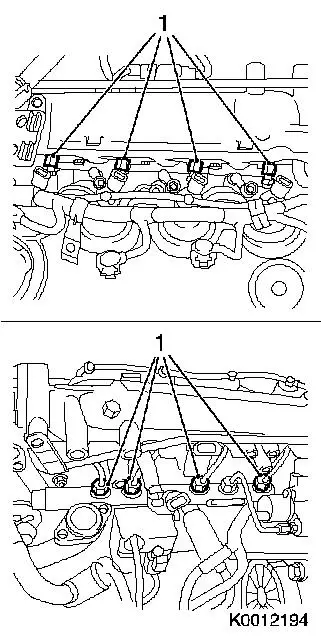

| 9. |

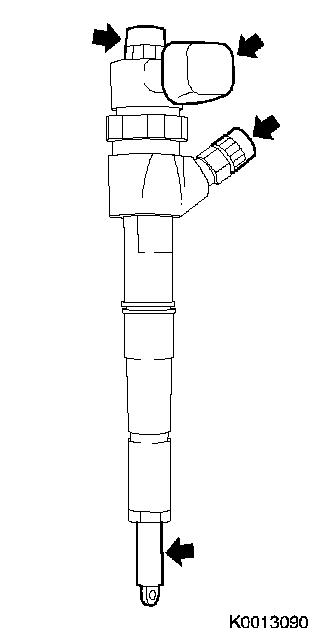

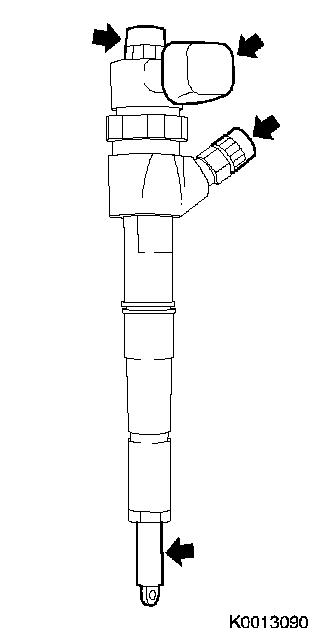

Remove 4x injector

Note: If the injectors

cannot be reached by hand, use EN-46786

together with KM-328-B . Fit plugs

1) to removed injectors (arrows).

|

|

|

| 10. |

Connect battery

| • |

Attach ground connection to ground terminal

|

|

| 11. |

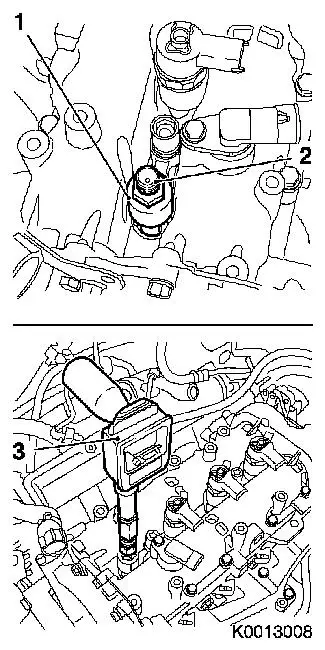

Attach compression plotter to cylinder 1

| • |

Attach EN-46791 (1) together with

EN-46783 (2)

|

| • |

Attach compression plotter (3) to EN-46791 , EN-46783

| – |

Measuring range 1000 to 4000 kPa 10 to 40 bar)

Note: Note

manufacturer's provisions.

|

|

|

|

|

Inspect

Inspect

| 12. |

Check compression of cylinder 1

Note: When compression

pressure is checked, 4 cm 3 of fuel will

leak out of the open accumulator fuel connections. Catch this fuel

with a cloth.

| • |

2nd mechanic is required.

|

| • |

Start engine for approx. 4 seconds

Note: Engine speed at

least 200 rpm.

|

| • |

Detach compression plotter

|

| • |

Remove EN-46791 , EN-46783

|

|

| 13. |

Repeat the test procedure on cylinders 2, 3 and 4

|

| 14. |

Compare compression values

| • |

Maximum pressure differential 150 kPa (1.5 bar)

|

|

Install

Install

| 15. |

Disconnect battery

| • |

Detach ground connection from ground terminal

|

|

| 16. |

Cleaning work

Note: Use EN-47632 (1) to clean the injector seats. Insert

EN-47632 with coarse fleece in the

injector shaft and clean the injector seat by turning. Finish by

cleaning with the fine fleece.

|

Important: High-pressure lines

must not be installed more than once. When fastening the retaining

nut counterhold against the injector with an open-ended wrench.

|

| 18. |

Install 4x new high pressure line

| • |

Tighten 4x retaining nut (M14) 23

Nm

|

| • |

Tighten 4x retaining nut (M12) 23

Nm

|

|

| 19. |

Attach wiring harness

| • |

Connect 4x injector wiring harness plug

|

|

| 20. |

Attach 4x oil leak line to injector

| • |

Clip 4x oil leak line into injector

|

| • |

Clip 2x oil leak line in bracket

|

|

| 21. |

Attach vacuum line

| • |

Attach 2x vacuum hose, vacuum unit to vacuum line

|

|

| 22. |

Install fuel pump relay

| • |

Detach relay holder cover

|

| • |

Attach relay holder cover

|

|

| 23. |

Connect battery

| • |

Attach ground connection to ground terminal

|

|

Important: Wear protective

goggles and protective gloves.

|

| 24. |

Fuel System, Check for Leaks

| • |

Start engine.

Note: Check fuel system

for escaping fuel.

|

|

| 26. |

Program volatile memories

|

1 ) protective caps are available in the opel parts

catalogue under catalogue number 45 06 154 / part number 9201697/

|