|

Repair engine using a short block

Remove Remove

| 1. |

Detach transmission from engine

| • |

For vehicles with manual transmission

|

| • |

For vehicles with automatic transmission

|

|

| 2. |

Vehicles with manual transmission: detach clutch

|

| 3. |

Vehicles with manual transmission: detach KM-6263

| • |

Turn rotating spindle back to initial position

|

|

| 4. |

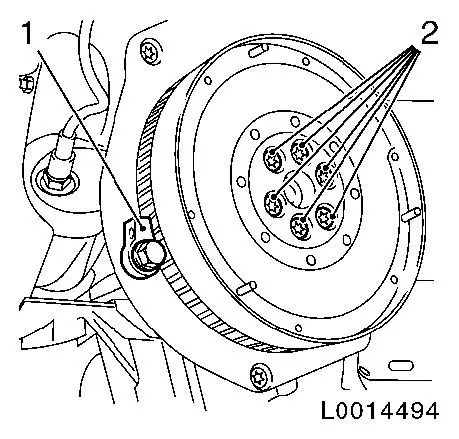

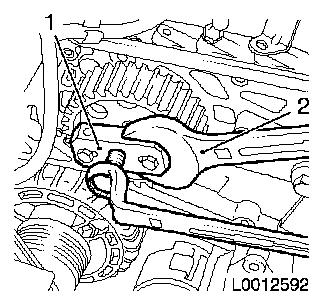

Vehicles with manual transmission: attach EN-46792 (1)

|

| 5. |

Vehicles with manual transmission: remove flywheel

|

|

|

| 6. |

Vehicles with automatic transmission: attach EN-46792 (2)

|

| 7. |

Vehicles with automatic transmission: remove drive disc

|

|

|

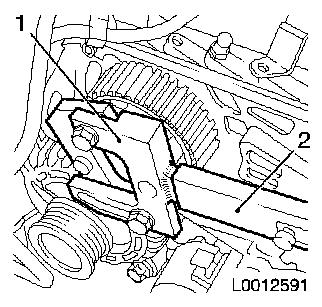

| 9. |

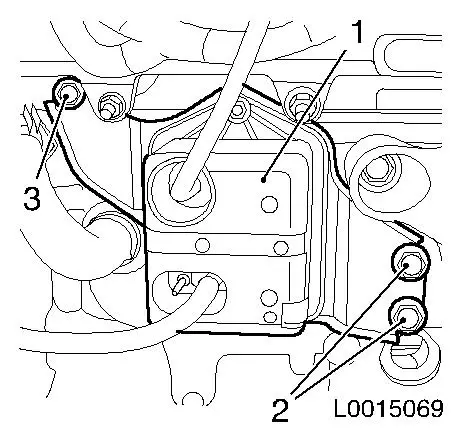

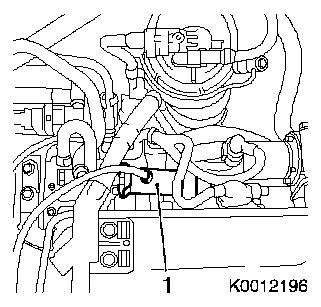

Detach vacuum reservoir (1) and retaining plate

Note: If present

|

|

|

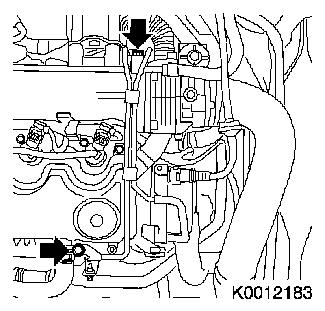

| 10. |

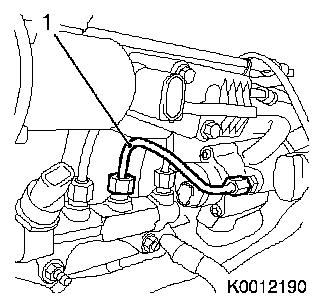

Detach EGR cooler (1)

| • |

Unscrew bolt, nut (arrows)

|

| • |

Detach EGR valve metal tube

|

|

|

|

| 11. |

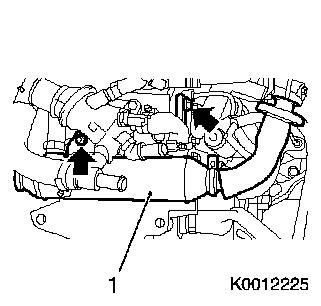

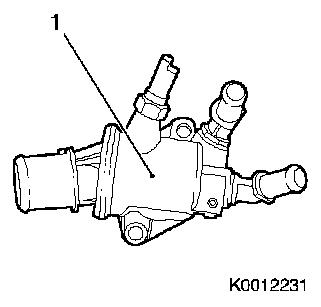

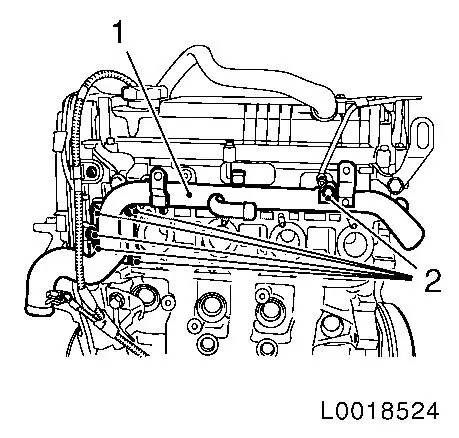

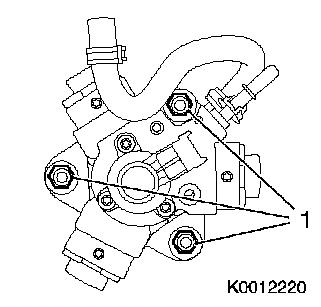

Remove thermostat housing (1)

| • |

Disconnect wiring harness connector.

|

|

|

|

| 12. |

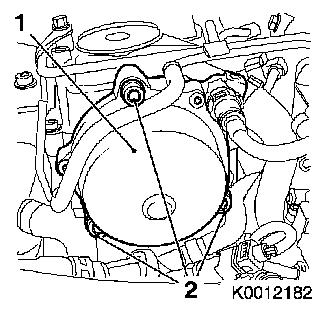

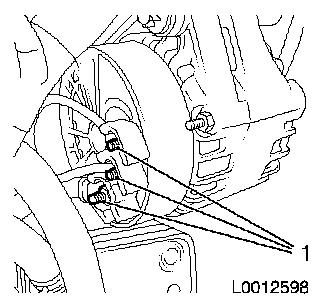

Remove vacuum pump (1)

|

|

|

| 13. |

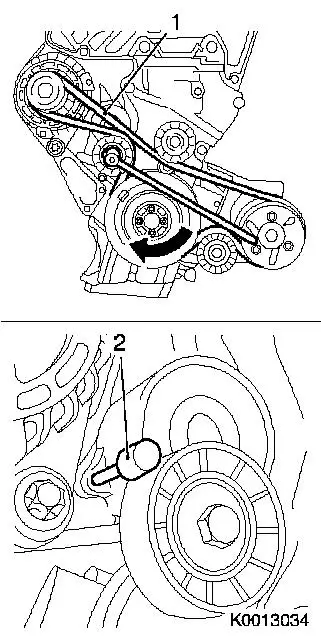

Remove ribbed V-belt (1)

| • |

Mark rotational direction of ribbed V-belt

|

| • |

Tension ribbed V-belt tensioner in direction of arrow

|

|

|

|

| 14. |

Remove compressor

| • |

Disconnect wiring harness plug (2)

|

|

|

|

| 15. |

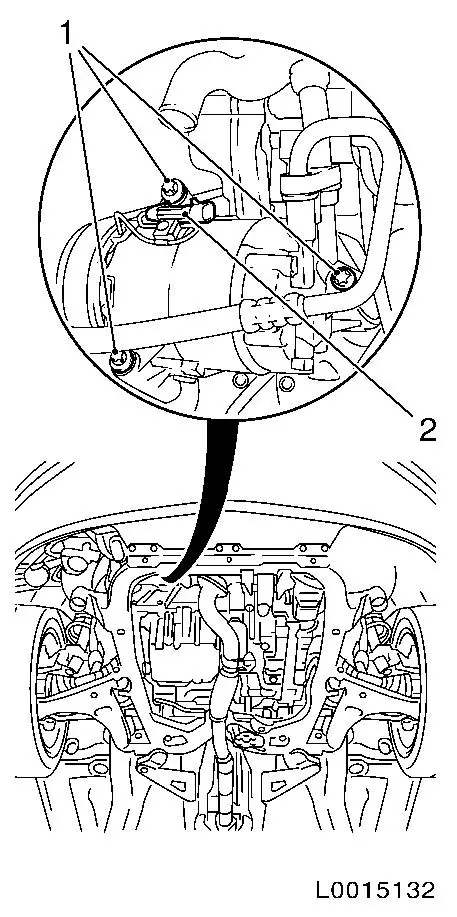

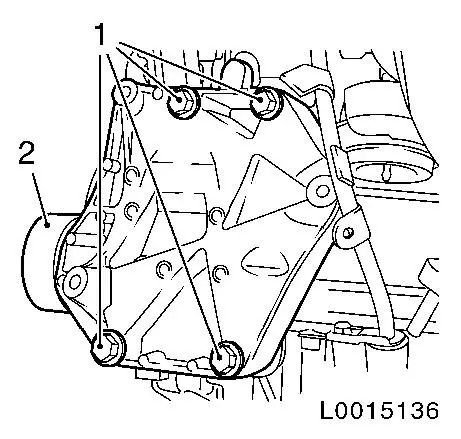

Detach compressor support from engine block

Note: Note guide

sleeves

| • |

Unscrew 4x bolts (1)

Note: Remove with

ribbed V-belt guide roller (2)

|

|

|

|

| 16. |

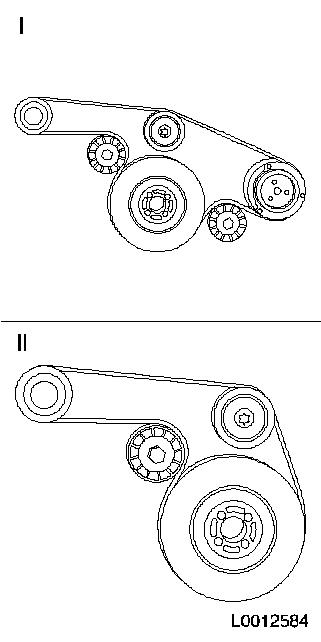

Detach 2x compressor wiring harness bracket

| • |

Unscrew 2x bolts

| – |

Set wiring harness aside

|

|

|

| 17. |

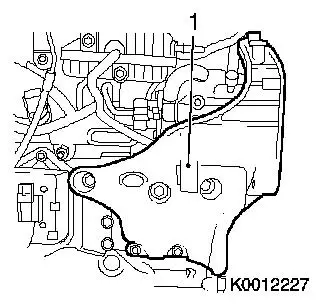

Remove coolant pipe assembly (1)

|

|

|

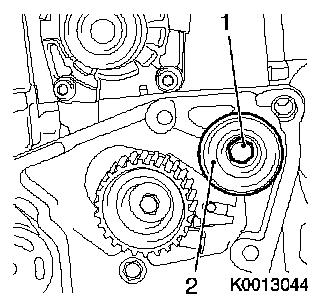

| 18. |

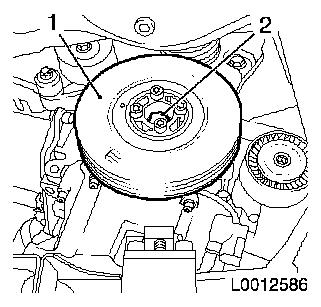

Remove torsional vibration damper (1)

| • |

Unscrew 4x bolts

Note: Counterhold

toothed belt drive gear at bolt (2)

|

|

|

|

| 19. |

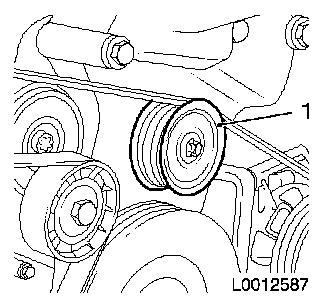

Remove upper ribbed V-belt guide roller (1)

|

|

|

| 20. |

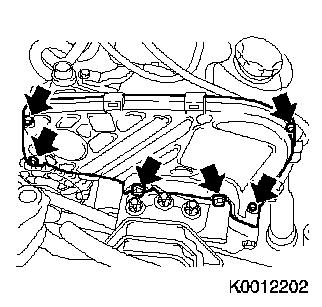

Remove toothed belt cover

| • |

Unscrew 6x bolt (arrows)

|

| • |

4x unclip camshaft sensor wiring harness

|

|

|

|

| 21. |

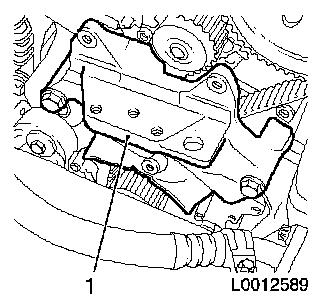

Remove engine damping block adapter (1)

| • |

Unscrew 5x bolts

Note: Note different

bolt lengths

|

|

|

|

| 22. |

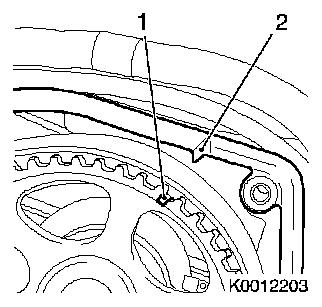

Set cylinder no. 1 to TDC of combustion stroke

| • |

The mark on the camshaft sprocket (1) must be aligned with the

mark on the camshaft housing cover (2)

|

|

|

|

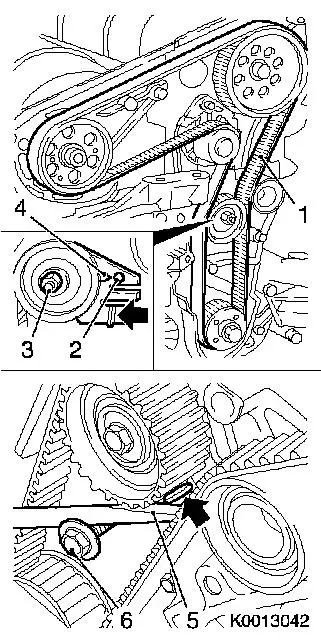

| 23. |

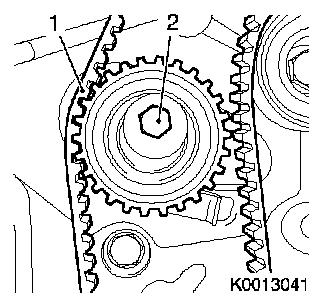

Remove toothed belt (1)

Note: Mark direction of

rotation

| • |

Slacken the toothed belt tension roller

|

|

|

|

| 24. |

Remove toothed belt tightening roller

|

| 25. |

Remove toothed belt guide roller (2)

|

|

|

| 26. |

Detach vacuum line

| • |

Unscrew 2x bolts (arrows)

|

|

|

|

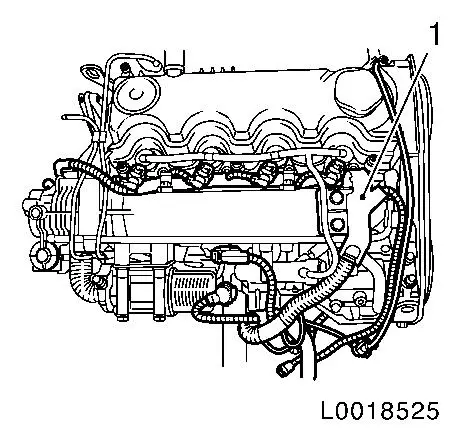

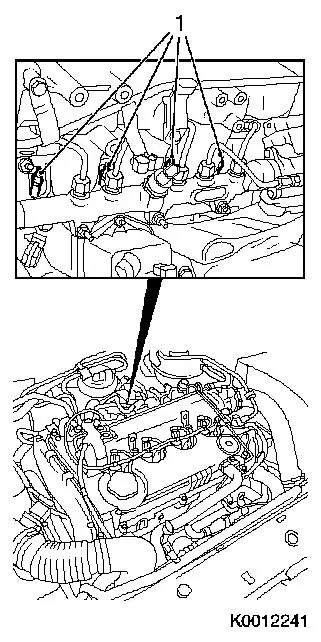

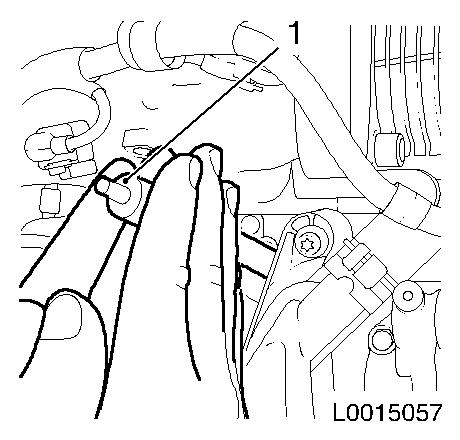

| 27. |

Detach witing harness (1) from engine

| • |

Detach wiring harness bracket from camshaft housing cover

|

| • |

Unclip 5x wiring harnesses

|

| • |

Disconnect 11x wiring harness plugs

| – |

Intake air temperature sensor

|

|

|

|

|

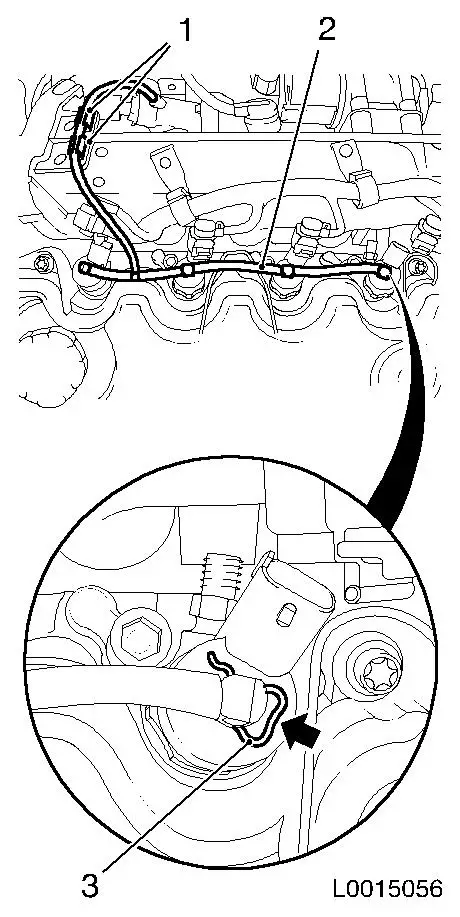

| 28. |

Detach 4x oil leak line (2) from injectors

Note: The oil leak line

must not be detached from the fuel return damping case. It if is

detached, it must be replaced.

| • |

Unclip 2x leak oil line (1)

|

| • |

Release 4x retaining clamp (3) from injector in direction of

arrow

Note: Seal 4x injectors

with suitable blanking plugs

|

|

|

|

| 29. |

Remove fuel return damping case (1) with oil leak line

Note: Open fuel

connections must be sealed with appropriate plugs

|

|

|

Important: After detaching the

high pressure lines, seal off injector and pressure chamber

openings with protective caps

1)

|

| 30. |

Detach accumulator high pressure line (1) to high pressure

pump

Important: When releasing the

retaining nut on the high pressure pump, counterhold with

open-ended wrench.

|

| • |

Unscrew 2x union nuts

Note: Fuel connections

that have been opened must be sealed with suitable plugs from the

kit (45 06 154).

|

|

|

|

| 31. |

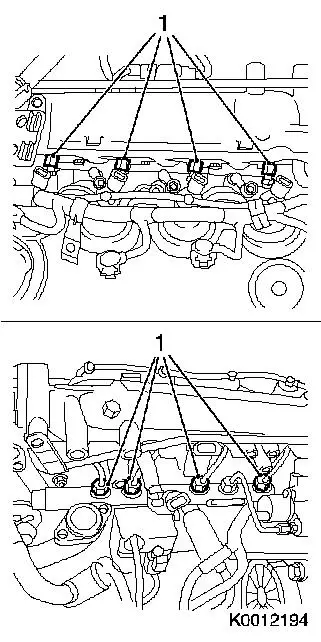

Detach 4x high pressure line - accumulator to injector

Important: When releasing the

retaining nut, counterhold with open-ended wrench against the

injector.

|

| • |

Unscrew 8x union nut (1)

Note: Open fuel

connections must be sealed with suitable blanking plugs

|

|

|

|

| 32. |

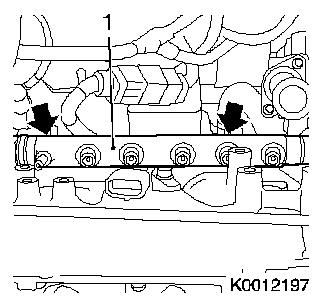

Remove accumulator (1)

| • |

Unscrew 2x nut (arrows)

|

|

|

|

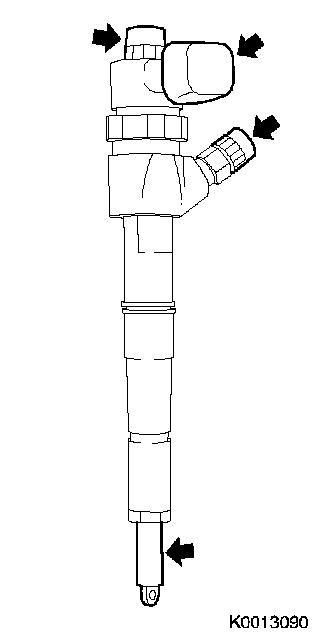

| 33. |

Remove 4x injector

Note: If the injectors

cannot be reached by hand, use EN-46786

together with KM-328-B . Fit plugs to

removed injectors (arrows).

|

|

|

| 34. |

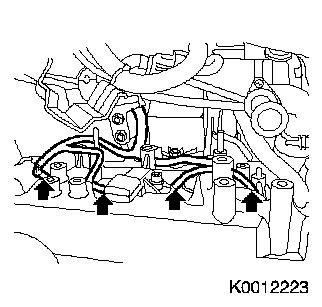

Detach wiring harness for sheathed glow plugs (arrows)

| • |

Disconnect 4x glow plug wiring harness plug

|

|

|

|

| 35. |

Remove 4x sheathed glow plug (1)

|

|

|

| 36. |

Release high-pressure pump gear

Note: Use a second

person

| • |

Counterhold with KM-6347 (1) in

combination with KM-956-1 (2)

|

|

|

|

| 37. |

Detach high-pressure pump gear

| • |

Pull off high-pressure pump drive gear

| – |

Counterhold with open-ended wrench (2)

|

|

|

|

|

| 38. |

Remove high pressure pump

|

|

|

| 39. |

Detach 3x alternator wiring harnesses

|

|

|

| 41. |

Detach high-pressure pump bracket (1)

| • |

Detach coolant pipe bracket from high-pressure pump bracket

|

| • |

Unscrew 6x bolts

Note: Note different

bolt lengths

|

|

|

|

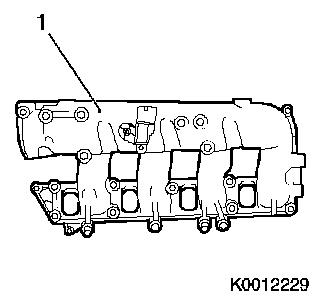

| 42. |

Remove intake manifold (1)

|

|

|

| 43. |

Detach alternator bracket

| • |

Unscrew 2x bolts

Note: Note different

bolt lengths

|

|

| 44. |

Detach cylinder head cover vent hose

|

| 45. |

Detach crankshaft housing vent hose

|

| 46. |

Detach charge air pipe bracket

|

| 47. |

Fit engine transport shackle

|

| 48. |

Hitch engine up to workshop crane.

|

| 49. |

Detach engine from KM-412

|

| 50. |

Detach KM-412-36-1 and KM-412-36-2 from engine block

|

| 51. |

Unhitch engine from workshop crane.

|

| 52. |

Detach engine transport shackle

|

Install

Install

| 53. |

Attach engine transportation shackle to engine short block

|

| 54. |

Hitch engine short block up to workshop crane

|

| 55. |

Attach KM-412-36-1 an KM-412-36-2 to engine block

|

| 56. |

Attach engine short block to KM-412

|

| 57. |

Unhitch engine short block from workshop crane.

|

Important: According to the

engine preparers' regulations all particles of dust and liquids

must be cleaned off every attaching part that is to be

reassembled.

|

| 58. |

Cleaning work on attaching parts

|

| 59. |

Detach engine transport shackle

|

| 60. |

Attach charge air pipe bracket

|

| 61. |

Attach crankshaft housing vent hose

|

| 62. |

Attach cylinder head cover vent hose

|

| 63. |

Attach alternator bracket

| • |

Tighten 2x bolts

Note: Note different

bolt lengths

|

|

| 64. |

Install intake manifold

| • |

Tighten 9x new nut 25 Nm

|

|

| 65. |

Attach high-pressure pump bracket

| • |

Tighten 6x bolt 25 Nm

Note: Note different

bolt lengths

|

| • |

Attach coolant pipe bracket to high-pressure pump bracket

|

|

| 66. |

Attach alternator

| • |

Tighten lower bolt 70 Nm

|

|

| 67. |

Attach alternator wiring harness

| • |

Tighten 2x nut (M6) 5 Nm

|

|

| 68. |

Install high pressure pump

|

| 69. |

Fit high pressure pump wheel

|

| 70. |

Fasten high-pressure pump gear

| • |

Counterhold with KM-6347 in

conjunction with KM-956-1

|

|

| 71. |

Tighten 4x sheathed glow plugs to 8

Nm

|

| 72. |

Attach wiring harness of sheathed glow plugs

| • |

Connect 4x wiring harness plug, sheathed glow plug

|

|

| 73. |

Cleaning work

| • |

Use EN-47632 (1) to clean the

injector seats. Insert EN-47632 with

coarse fleece in the injector shaft and clean the injector seat by

turning. Finish by cleaning with the fine fleece.

|

|

|

|

| 76. |

Install 4x new high-pressure line, accumulator to injector

| • |

Tighten 4x union nut (M14) 23 Nm

|

Important: Pressure lines must

not be installed more than once. When fastening the retaining nut

counterhold against the injector with an open-ended wrench.

|

| • |

Tighten 4x union nut (M12) 23 Nm

|

|

| 77. |

Attach new high pressure line - accumulator to high pressure

pump

| • |

Tighten union nut (M14) 23 Nm

|

Important: Pressure lines must

not be installed more than once. When fastening the union nut to

the high-pressure pump, counterhold against it with an open-ended

wrench.

|

| • |

Tighten union nut (M12) 23 Nm

|

|

| 78. |

Install fuel return damping case with oil leak line

| • |

Tighten 2x bolts

| – |

Attach wiring harness bracket to fuel return damping case

|

|

|

| 79. |

Attach 4x oil leak line to injectors

| • |

Clip 4x oil leak line to injector

|

|

| 80. |

Attach wiring harness to engine

| • |

Clip in 5x wiring harnesses

|

| • |

Connect 11x wiring harness plug

| – |

Intake air temperature sensor

|

|

| • |

Clip in 2x leak oil line

|

| • |

Attach wiring harness bracket to camshaft housing cover

|

|

| 83. |

Install toothed belt guide roller

| • |

Tighten bolt 50 Nm

Note: Use screw locking

compound (red)

|

|

| 85. |

Fit toothed belt tightening roll

Note: Insert tension

roller in guide

| • |

Use screw locking compound (red)

|

|

| 86. |

Install toothed belt

Note: Observe direction

of rotation

Important: Tightened end (1) must

be taut

|

| • |

Position toothed belt

|

|

| 87. |

Tension the toothed belt

| • |

Tension the toothed belt

Note: Push adjusting

lever in direction of arrow with a screwdriver (5) until pointer

(4) of toothed belt tension roller aligns with mark (2)

|

| • |

Tighten bolt, toothed belt tension roller (3) 25 Nm

|

|

|

|

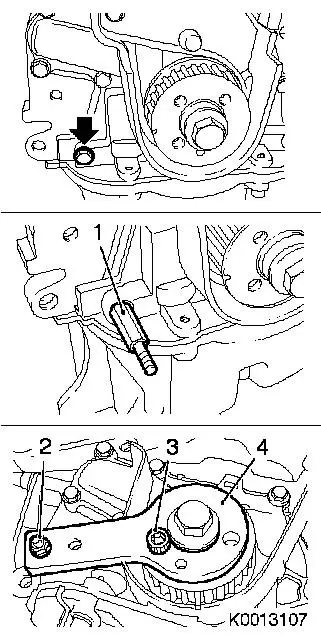

| 88. |

Check crankshaft setting with EN-46788

| • |

Unscrew oil pump bolt (arrow)

|

| • |

Tighten stud bolt (1) EN-46788

|

| • |

Attach positioning disk (4) EN-46788

|

| • |

Detach positioning disk EN-46788

|

|

|

|

| 89. |

Timing, Check

| • |

Turn crankshaft 720° in the

direction of rotation of the engine

|

| • |

Check camshaft position

| – |

The mark on the camshaft sprocket must align with the mark on

the cylinder head cover.

|

|

|

| 90. |

Check crankshaft setting with EN-46788

Note: If EN-46788 cannot be fitted, repeat the toothed belt

positioning procedure

| • |

Attach positioning disk EN-46788

|

| • |

Remove positioning disk and stud bolt EN-46788

|

| • |

Tighten oil pump bolt 9 Nm

|

|

| 91. |

Install engine damping block adapter

Note: Note different

bolt lengths

| • |

Tighten 3x bolt (M10) 50 Nm

|

| • |

Tighten 2x bolt (M8) 25 Nm

|

|

| 92. |

Install toothed belt cover

| • |

Tighten 4x bolt (M6) 9 Nm

|

| • |

Tighten 2x bolt (M8) 25 Nm

|

| • |

4x clip in camshaft sensor wiring harness

|

|

| 93. |

Install upper ribbed V-belt guide roller

|

| 94. |

Install torsional vibration damper

Note: Observe correct

fitting position

| • |

Tighten 4x bolt 25 Nm

Note: Counterhold

toothed belt drive gear at bolt

|

|

| 95. |

Install coolant pipe assembly

|

| 96. |

Attach 2x compressor wiring harness bracket

|

| 97. |

Attach compressor support to engine block

Note: Note guide

sleeves

|

| 98. |

Attach compressor to support

| • |

Fix wiring harness plug

|

|

| 99. |

Insert ribbed V-belt

Note: Note direction of

travel

| • |

Position ribbed V-belt

| – |

I Route of ribbed V-belt with air conditioning

|

| – |

II Route of ribbed V-belt without air conditioning

|

|

|

|

|

| 100. |

Clean sealing surface

|

| 102. |

Clean sealing surface

|

| 103. |

Install thermostat housing

| • |

Fix wiring harness plug

|

|

| 104. |

Insstall EGR cooler

| • |

Attach EGR valve metal tube

|

|

| 105. |

Attach vacuum reservoir and retaining plate

|

| 108. |

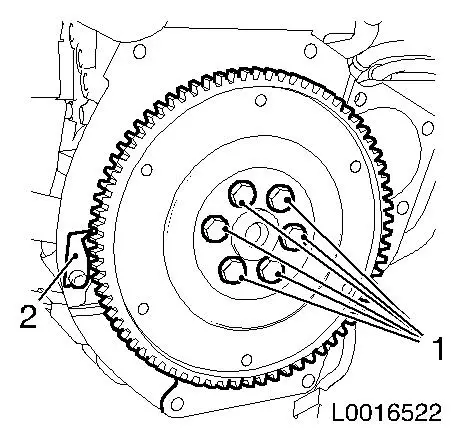

Vehicles with automatic transmission: install drive disc

| • |

Tighten 6x new bolt 160 Nm

|

|

| 109. |

Vehicles with manual transmission: install flywheel

| • |

Tighten 6x new bolt 160 Nm

|

|

| 110. |

Vehicles with manual transmission: attach KM-6263

Important: Fasten KM-6263 but only to engine block, not to oil pan

|

| • |

Tighten 4x bolts

|

| • |

Insert clutch pin KM-6263-30 with

KM-6263-22

|

|

| 111. |

Vehicles with manual transmission: install clutch

|

| 112. |

Detach transmission from engine

| • |

Remove automatic transmission from engine

|

| • |

Remove manual transmission from engine

|

|

1 ) Protective caps are available from the Opel

parts catalogue under catalogue number 45 06 154 / part number:

9201697

|