|

Front Crankshaft Seal Ring, Replace

Remove Remove

| 2. |

Disconnect battery

| • |

Detach ground connection from ground terminal

|

|

| 4. |

Remove air cleaner housing

|

| 5. |

Raise vehicle by its full height

|

| 6. |

Remove lower engine cover and right engine splash guard

|

| 7. |

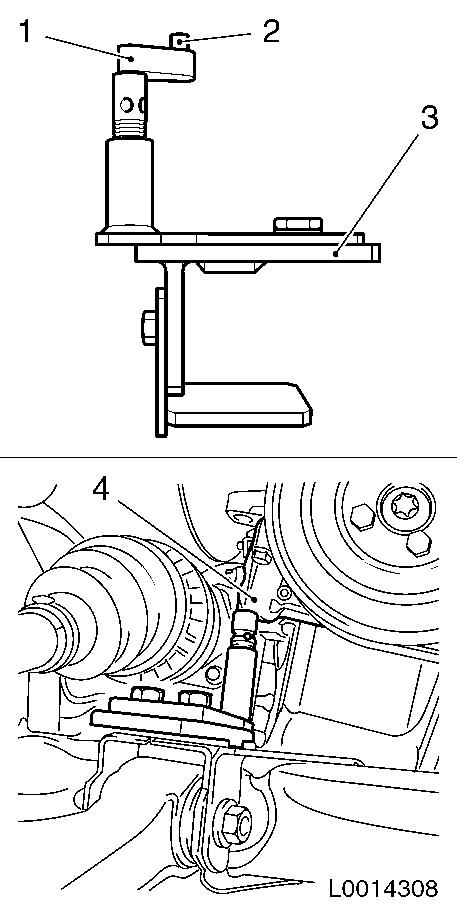

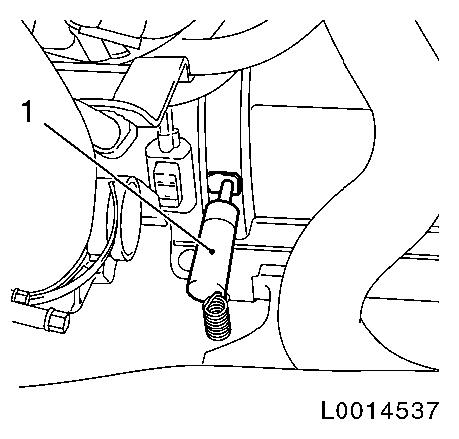

Insert KM-6173 (3)

| • |

Align support bearing (1)

|

| • |

Raise support bearing until journal (2) sits flush in mount

(4)

|

|

|

|

|

| 8. |

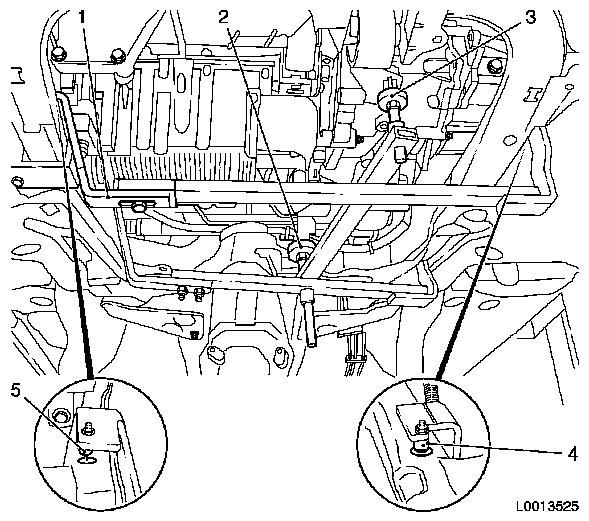

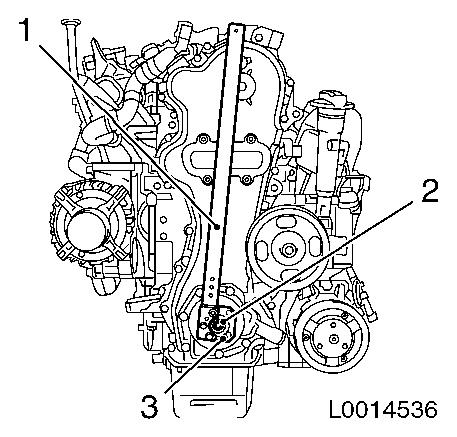

Fit KM-6001-A

Note: Attaching KM-6001-A guarantees perfect alignment of the

drive unit with the front axle body

| • |

Detach front right bracket (1)

|

| • |

Attach front right bracket

|

| • |

Insert journals (4) and (5) in guide holes in front axle

body

|

| • |

Fasten 3x screw connection on guide rail

|

| • |

Adjust support bearings (2) and (3)

Note: The guide

journals must be seated free from play in the support bearings

|

|

|

| 9. |

Lower vehicle by its full height

|

| 10. |

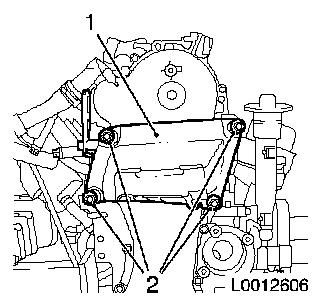

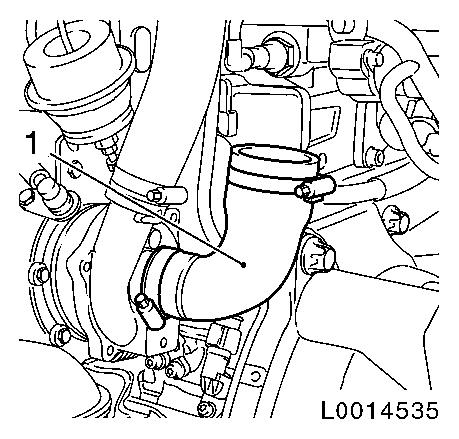

Remove engine damper block (1)

| • |

Unscrew 6x bolts (2) and (3)

|

| • |

Remove with engine damping block bracket

|

|

|

|

| 11. |

Remove engine damping block adapter (1)

|

|

|

| 13. |

Remove ribbed V-belt tensioner

|

| 14. |

Remove torsional vibration damper

|

| 15. |

Remove air intake pipe

|

| 16. |

Remove air intake hose

|

|

|

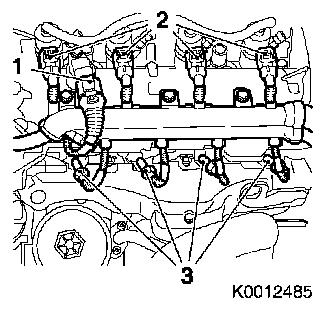

| 17. |

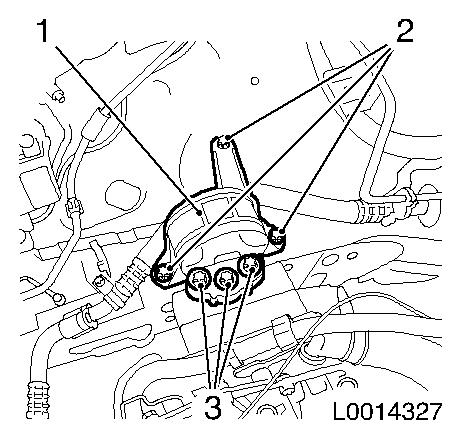

Detach engine management wiring harness

| • |

Disconnect 4x wiring harness plugs for injector (2)

|

| • |

Disconnect 4x wiring harness plugs, sheathed glow plug (3)

|

| • |

Disconnect wiring harness plug for camshaft sensor (1)

|

|

|

|

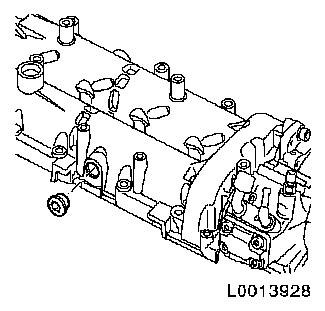

| 18. |

Remove closure bolt from camshaft housing exhaust side

|

|

|

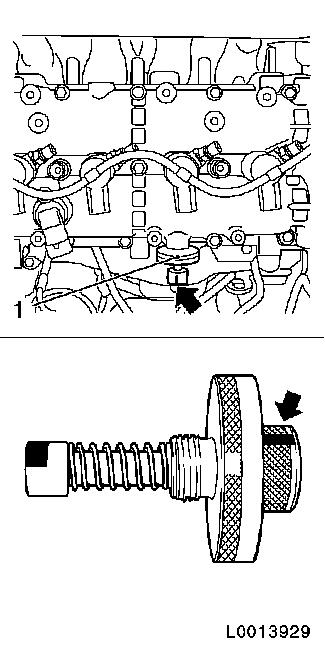

| 20. |

Disconnect exhaust camshaft

| • |

Screw in camshaft reference drift EN-46781 (1)

|

| • |

Ensure correct installation position

Note: Fixing for

reference drift must be installed in the horizontal position. To do

this, apply marking to reference drift as an aid (arrow)

|

|

|

|

| 21. |

Lock exhaust camshaft

| • |

Turn crankshaft in the direction of engine rotation by the bolt

on the torsional vibration damper flange until EN-46781 engages in the exhaust camshaft

|

|

| 22. |

Lock crankshaft, insert EN-46785 (1)

through bore in transmission housing

| • |

Turn crankshaft carefully at bolt for torsional vibration

damper flange until EN-46785 engages in

flywheel

|

|

|

|

| 23. |

Detach torsional vibration damper flange (3)

Note: Left-handed

thread

| • |

Unscrew bolt (2)

| – |

Counterhold with KM-662-C (1)

|

|

|

|

|

| 24. |

Raise vehicle by its full height

|

| 25. |

Remove front crankshaft seal ring from timing case

Note: Prise out with a

suitable tool

|

Install

Install

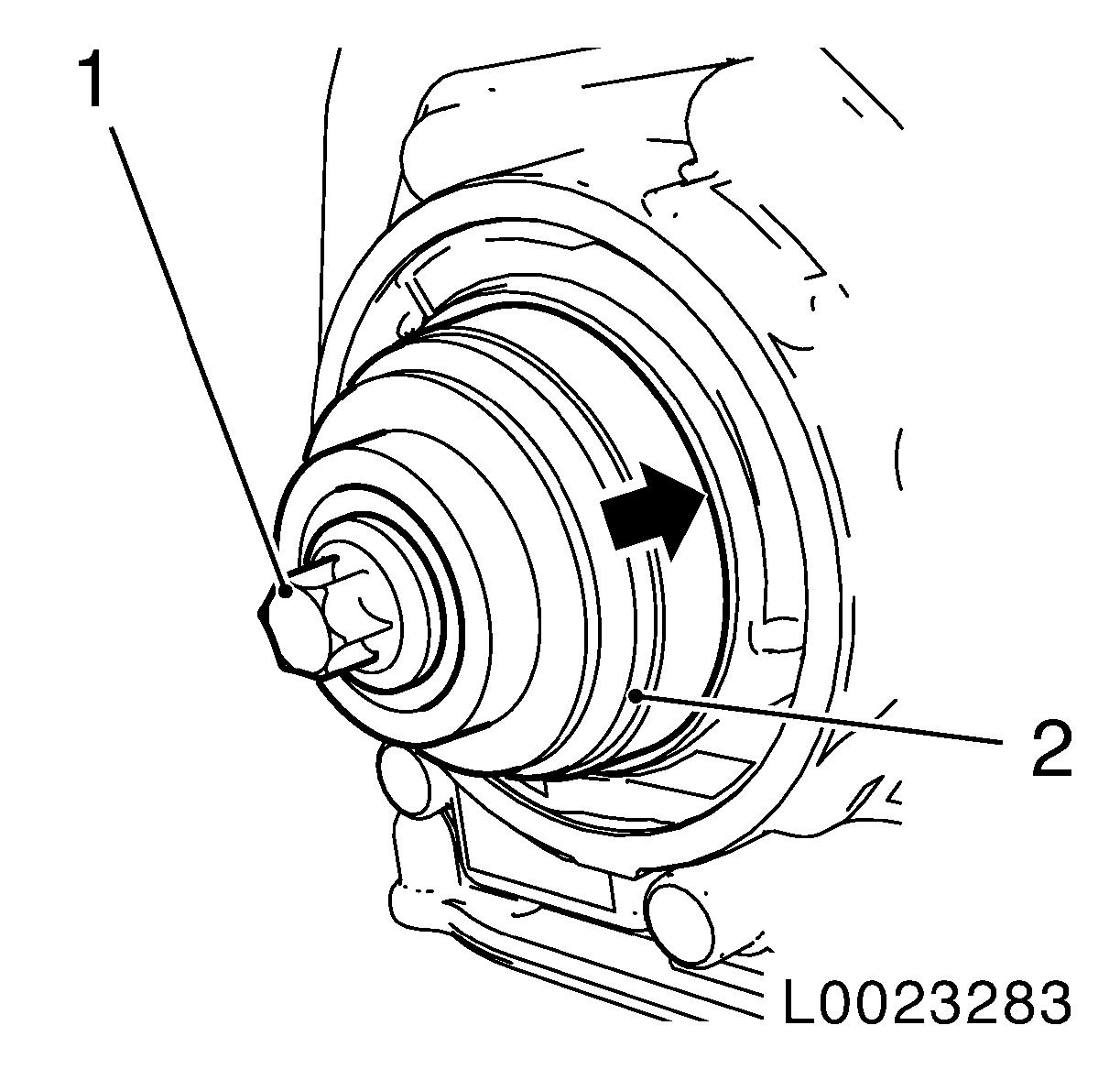

| 26. |

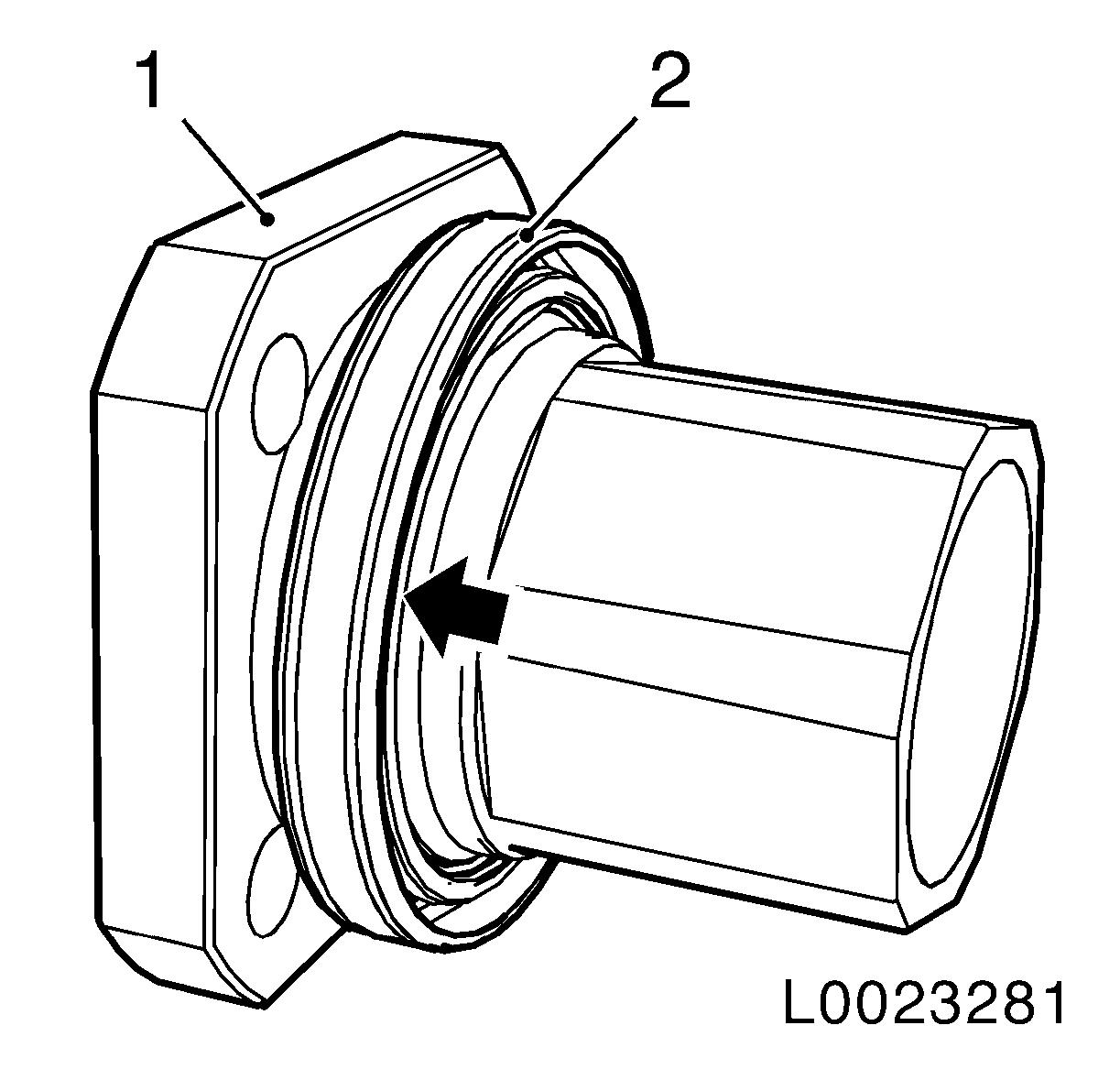

Push front crankshaft seal ring (2) onto sealing surface

torsional vibration damper flange (1) (arrow)

|

|

|

| 27. |

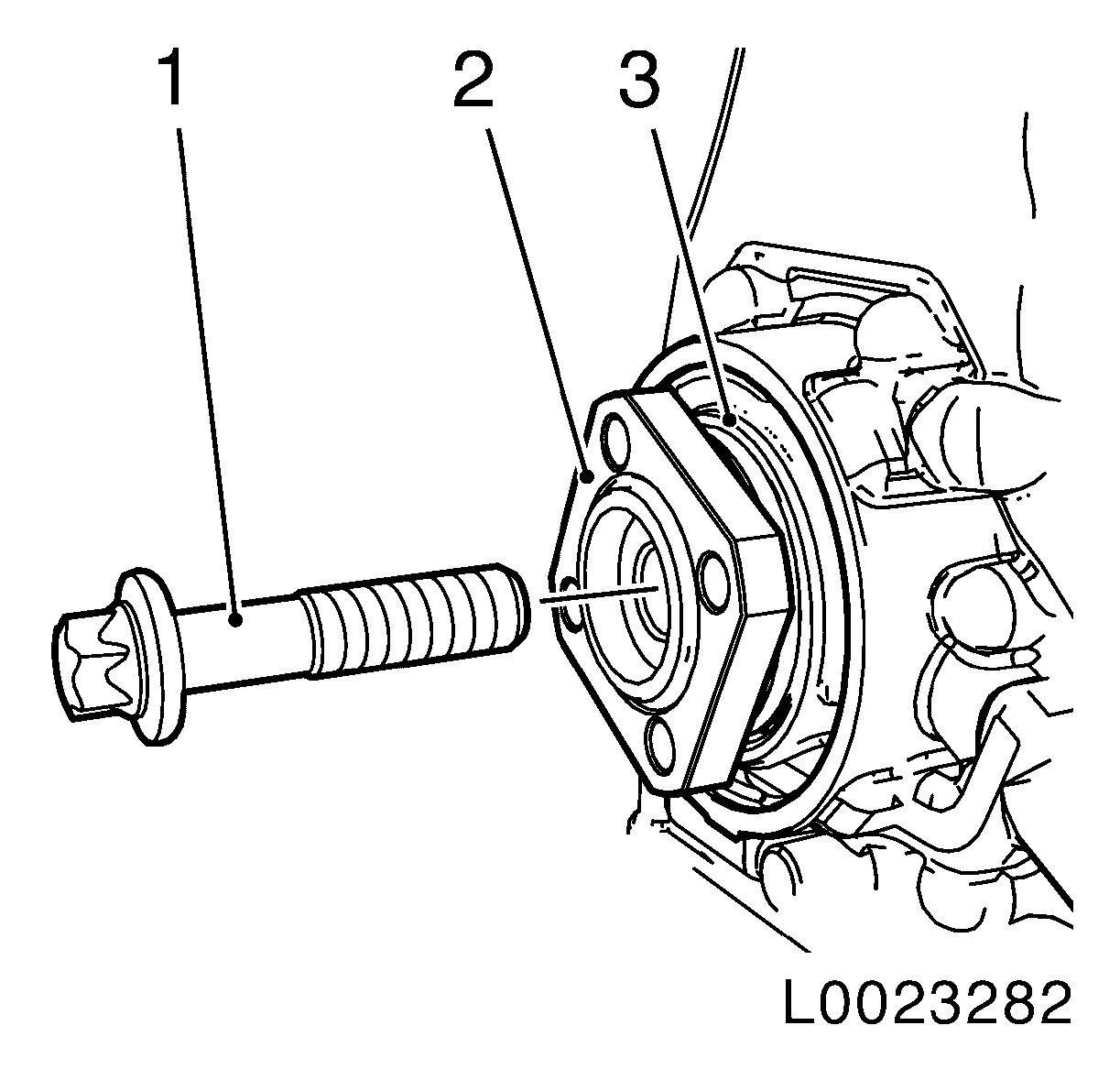

Install torsional vibration damper flange (2) with front

crankshaft seal ring (1).

| • |

Carefully tighten bolt to crankshaft stop

|

| • |

Remove torsional vibration damper flange

|

|

|

|

| 28. |

Press in seal ring with flat side of EN-46775 (2)

| • |

Carefully tighten bolt (1) until EN-46775 lies on timing case (arrow)

|

|

|

|

| 30. |

Lower vehicle by its full height

|

| 31. |

Attach torsional vibration damper flange

Note: Left-handed

thread

| • |

Tighten bolt 230 Nm

| – |

Counterhold with KM-662-C

|

|

|

| 32. |

Remove EN-46785 and EN-46781

|

| 33. |

Timing, Check

| • |

Turn crankshaft 700° in the

direction of engine rotation by the bolt on the torsional vibration

damper flange

|

| • |

Turn crankshaft in the direction of engine rotation until EN-46781 engages in the exhaust camshaft

|

| • |

Turn crankshaft until EN-46785

engages in the flywheel

|

| • |

If EN-46785 does not engage in the

flywheel, the procedure "Set Timings" must be repeated

|

|

| 34. |

Remove EN-46785 and EN-46781

|

| 35. |

Install closure bolt

| • |

Coat bolt with screw locking compound (red) and insert

Note: Complete assembly

work within 10 minutes.

|

| • |

Tighten closure bolt 15 Nm

|

|

| 36. |

Attach engine management wiring harness

| • |

Connect 4x injector wiring harness plug

|

| • |

Connect wiring harness plug, camshaft sensor

|

|

| 37. |

Install air intake hose

|

| 38. |

Install air intake pipe

|

| 39. |

Install torsional vibration damper

|

| 40. |

Install ribbed V-belt tensioner

|

| 41. |

Install ribbed V-belt

|

| 42. |

Install engine damping block adapter

|

| 43. |

Install engine damper block

| • |

Attach to engine damping block bracket

|

|

| 44. |

Raise vehicle by its full height

|

| 45. |

Remove engine mount KM-6173

|

| 46. |

Remove engine mount KM-6001-A

|

| 47. |

Install lower engine cover and right engine splash guard

| • |

Install 2x body-bound rivets

|

|

| 48. |

Lower vehicle by its full height

|

| 49. |

Install air cleaner housing with air intake hose

|

| 51. |

Program volatile memories

|

|