|

Crankshaft Bearing Play, Check (with

Plastigage)

Remove Remove

| 1. |

Detach cylinder block base plate with crankshaft bearing

shells

|

| 2. |

Measure bearing play with Plastigage (deformable plastic

thread)

Note: "Plastigage" is

available for various tolerance ranges

| • |

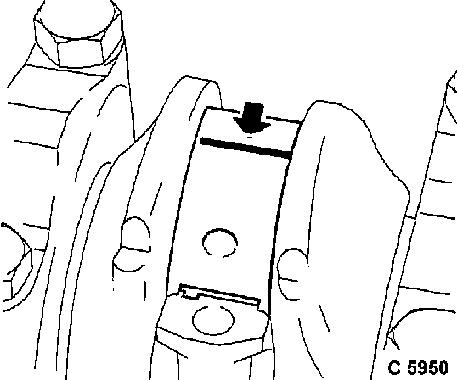

Cut thread to match the width of the con-rod bearing

|

| • |

Place thread axially between con-rod bearing journal and

con-rod bearing shell

|

|

| 3. |

Attach cylinder block base plate to cylinder block

Note: To prevent thread

from breaking when removing cylinder block base plate, remove

grease from con-rod journal and lightly oil crankshaft bearing

bearing shell. Do not rotate crankshaft.

| • |

Tighten 10x bolt M8 (inner) 25 Nm +

60°

Note: The old bolts can

be used for the measuring process

|

| • |

Tighten 12x bolt outer (M6) 10 Nm +

60°

Note: The old bolts can

be used for the measuring process

|

|

|

|

| 4. |

Detach cylinder block base plate

|

| 5. |

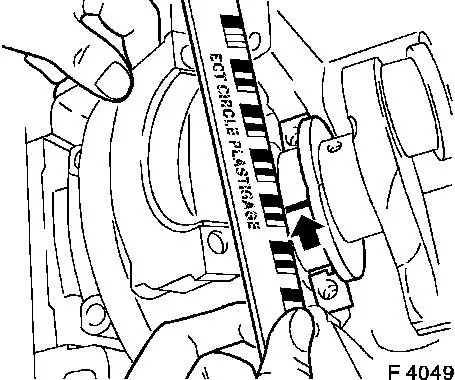

Measure crankshaft bearing play

| • |

Measure width of the flattened Plastigage thread with the

measuring scale (arrow)

Note: Do not mix up

millimetre and inch data on the measuring scale

| – |

Permissible crankshaft bearing play: 0.007 to 0.031 mm

|

|

|

|

|

| 6. |

Clean con-rod bearing, crankshaft bearing and crankshaft

|

Install

Install

| 7. |

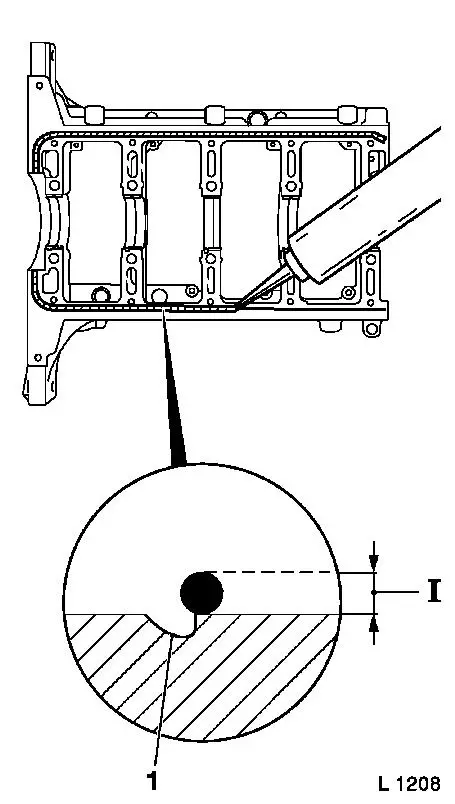

Apply silicone sealing compound

Note: The base plate

cylinder block must be fitted within 10 minutes of applying the

silicone sealing compound

Important: Do not lay bead of

silicone sealing compound in the groove or on the inner edge

|

| • |

Apply a bead of silicone sealing compound on the outside edge

of the groove (1) of the cylinder block base plate

| – |

approx 2 mm (dimension I) thick

|

|

|

|

|

| 8. |

Attach cylinder block base plate

| • |

Attach cylinder block base plate hand-tight to cylinder

block

|

| • |

Tighten 10x bolt M8 (inner) 25 Nm +

60°

|

| • |

Tighten 12x bolt outer (M6) 10 Nm +

60°

|

|

|