|

Multi-disc Brakes B3 and Freewheel F2, Remove and

Install (AF22)

Remove Remove

Important: Secure converter so it

does not fall out

|

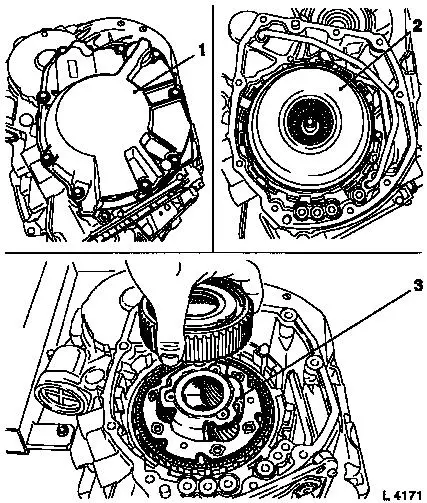

| 1. |

Remove transmission

|

| 2. |

Attach transmission to KM-694-A

(2)

| • |

Attach assembly to KM-113-2 (1)

|

|

| 3. |

Remove oil drain bolt (3)

| • |

Drain transmission fluid and collect for damage diagnosis

|

|

|

|

|

| 6. |

Remove drive shaft assembly (2) with multi-plate clutch C1 and

C2

|

| 7. |

Remove planetary gear set P1 (3)

|

|

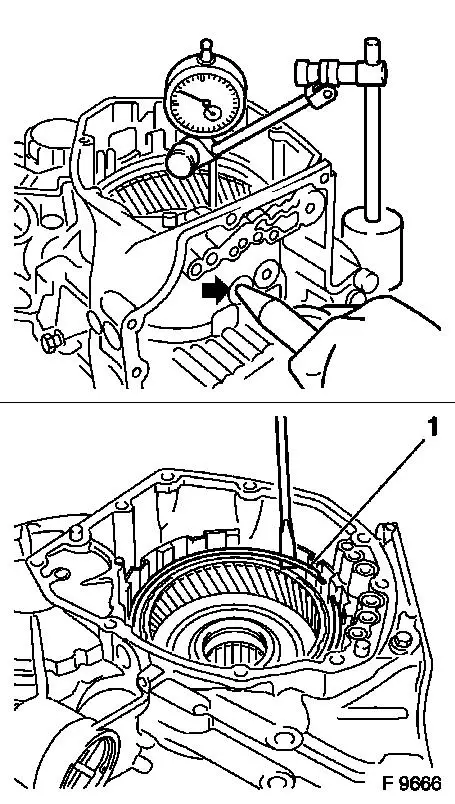

| 9. |

Measure piston stroke of multi-disc brakes B3 using dial gauge

MKM-571-B

Note: Replace liner

plates if necessary and correct piston stroke by installing a

suitable compensating flange from the "Service" Department.

| • |

Cut off the end of KM-994 and insert

KM-994 in hole

|

| • |

Blow in air at low pressure (4 bar) (arrow)

|

| • |

Place button on plate

Note: Measured value:

1.75 to 2.55 mm

|

|

| 10. |

Measure clearance between piston and set of discs using feeler

gauge

Note: Replace set of

discs if necessary.

| • |

Measured value: 0.6 to 1.9 mm

|

|

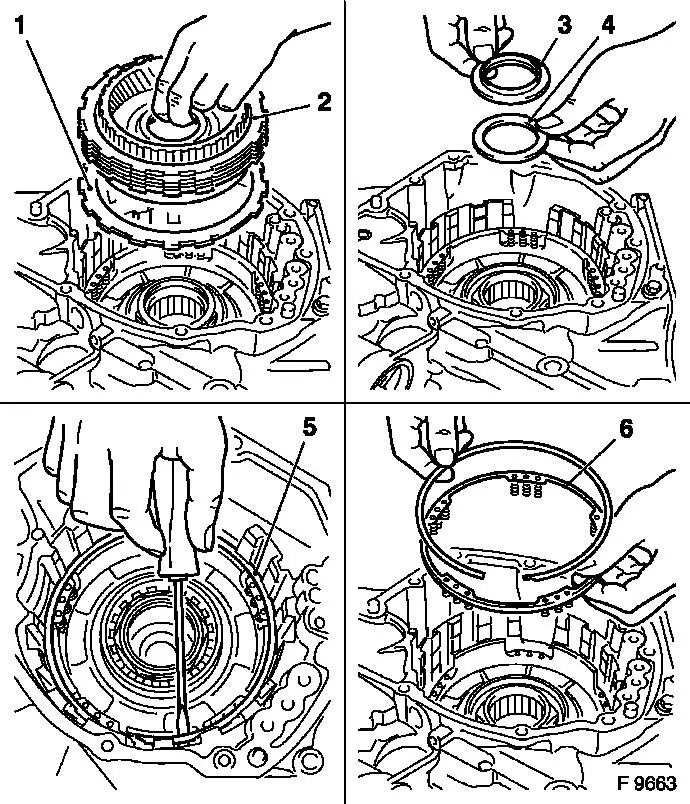

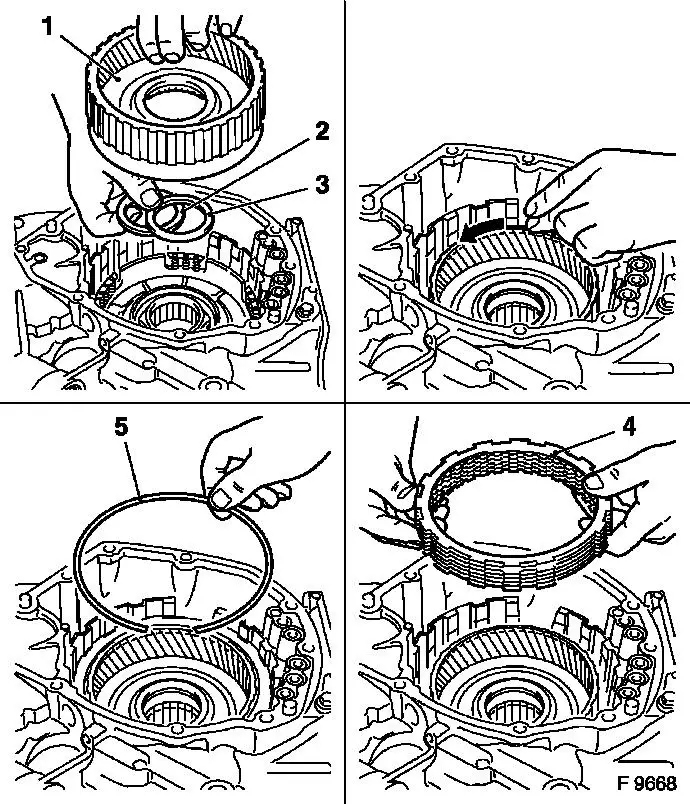

| 11. |

Prise off retainer (1) for front ring gear with screwdriver and

remove

|

|

|

|

| 12. |

Remove assembly (2) with steel plates, liner plates and flange

(1) for multi-disc brakes B3

|

| 13. |

Remove thrust bearing (4) with ball race (3)

|

| 14. |

Check steel and liner plates for damage and wear

Note: Place new liner

plates in transmission fluid for at least 2 hours before

fitting.

|

| 15. |

Remove return spring assembly

| • |

Prise off screwdriver (5) for return spring assembly (6) with

screwdriver

|

| • |

Remove return spring assembly

|

|

|

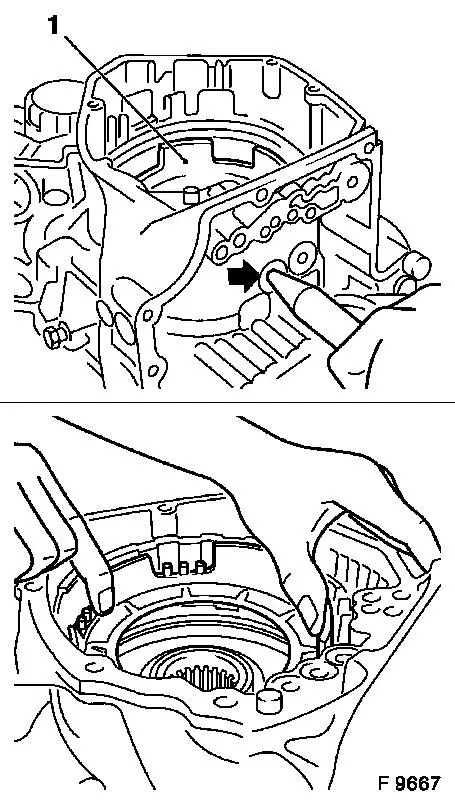

| 16. |

Remove piston (1) for multi-disc brakes B3

| • |

Cut off the end of KM-994 and insert

KM-994 in oil hole

|

| • |

Blow air at low pressure (4 bar) (arrow) into oil hole

|

| • |

Press out piston evenly without jamming

Note: Assist with

pliers if necessary

|

|

| 17. |

Replace seal rings on piston, inside and out

|

| 18. |

Clean components and check for damage

Note: Replace if

necessary.

|

| 19. |

Insert piston for multi-disc brakes B3 evenly in transmission

without jamming

Note: Spring mounting

faces upwards.

|

| 20. |

Insert return spring assembly in spring mounting of piston

B3.

|

|

|

Install

Install

|

| 21. |

Insert thrust bearing (2) with ball race (3) - for allocation

and direction of installation, see illustration "Thrust bearing

installation"

| • |

Install front ring gear assembly (1) with freewheel F2 in

transmission

Note: Front ring gear

must be rotatable in counterclockwise direction (arrow)

|

|

| 22. |

Install set of discs B3 (4) in transmission

| • |

Insert 6x liner plate and 5x steel plate, alternating

Note: Steel plate dogs

must be flush with the cut-outs in the transmission.

|

| • |

Insert new retainer (5)

Note: Ensure it is

seated perfectly.

|

|

|

|

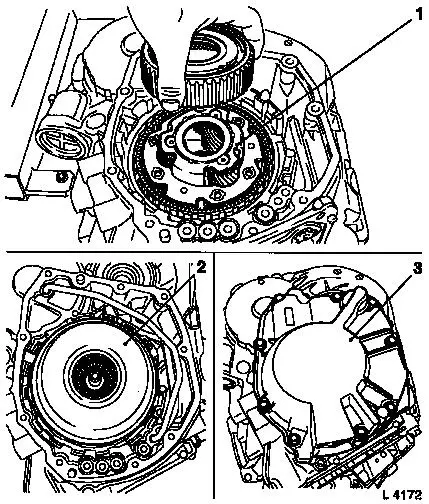

| 24. |

Install planetary gear set P1 (1)

|

| 25. |

Install drive shaft assembly (2) with multi-plate clutch C1 and

C2

|

| 26. |

Install rear cover (3)

|

|

Important: Secure converter so it

does not fall out

|

| 27. |

Install converter

|

| 28. |

Attach oil drain bolt (3) to transmission with seal ring

Note: Use new seal

ring.

| • |

Tighten oil drain bolt 40 Nm

|

|

| 29. |

Detach transmission assembly with KM-694-A from KM-113-2

(1)

| • |

Detach transmission from KM-694-A

(2)

|

|

| 30. |

Install transmission

| • |

Top up with transmission fluid

|

|

| 31. |

Check and correct transmission fluid level

|

|

|

|