|

Gearshift Module, Remove and Install (F17+

MTA)

Note: External

current reaching the gearshift module can cause damage. To

guarantee correct findings, a dismantled gearshift module should

not be reassembled.

Remove Remove

| 1. |

Put transmission into neutral

| • |

Depress footbrake and move selector lever to "N" position

|

|

| 2. |

Remove battery support

|

| 3. |

Remove hydraulic modulator

|

|

| 4. |

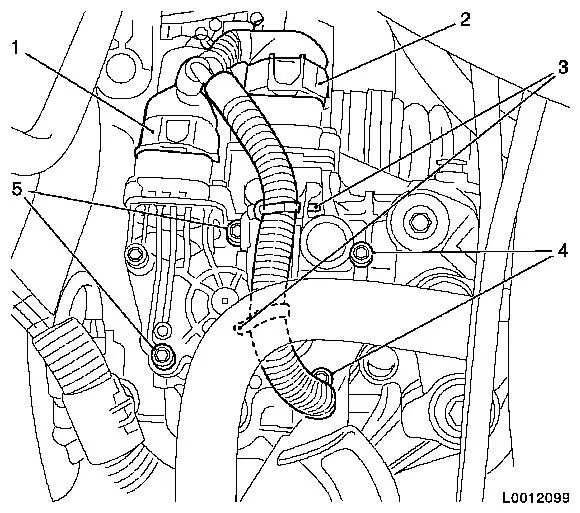

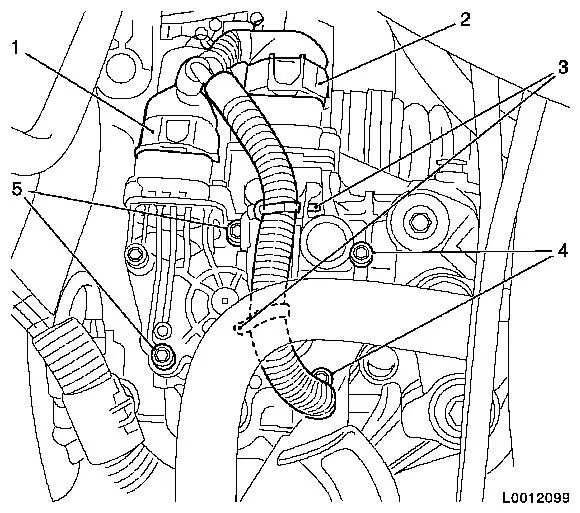

Disconnect 2x wiring harness plug (1) and (2) from gearshift

module

| • |

Detach 2x cable tie (3)

|

|

| 5. |

Remove gearshift module

| • |

Unscrew 4x bolt (4) and (5)

|

| • |

Lift gearshift module, tilt forwards and remove

|

|

|

|

Important: If removal in this way

is not possible, e.g. if there is a fault, the selector motor and

gearshift motor must be removed individually. A dismantled

gearshift module may not be used again and must be replaced.

|

| 6. |

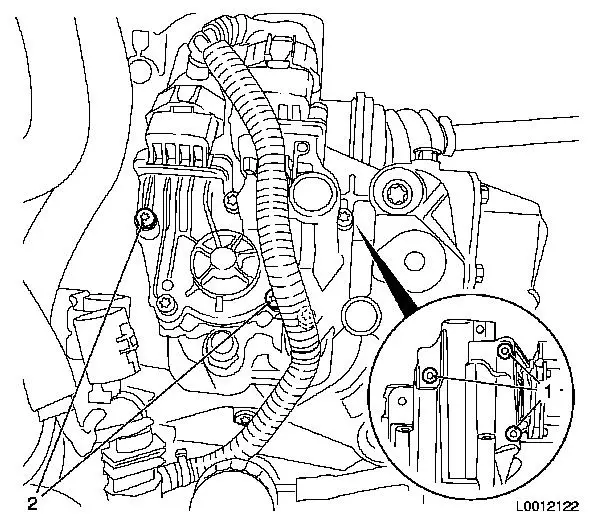

Remove selector motor and gearshift motor individually

Note: Only for

defective gearshift module.

| • |

Remove selector motor

| – |

Unscrew 3x bolt (1) and remove selector motor

|

|

| • |

Remove gearshift motor

| – |

Unscrew 2x bolt (2) and remove gearshift motor

|

|

|

|

|

| 7. |

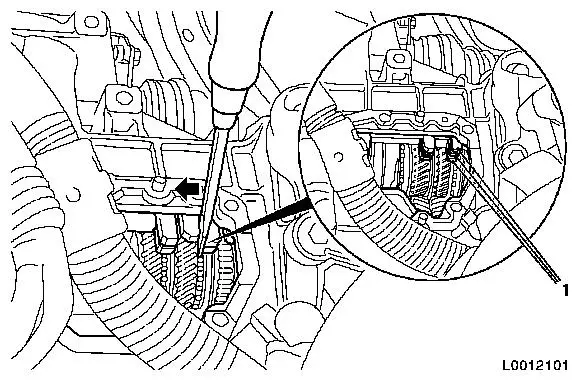

Put transmission into neutral

Note: Only necessary

for defective gearshift module.

| • |

Move shift forks to neutral position with a screwdriver

Note: All 3 shift forks

(1) must align and reverse gear may not be engaged.

|

|

|

| 8. |

Clean sealing surfaces

| • |

Clean sealing surface and threaded bores for gearshift

module

|

|

Install

Install

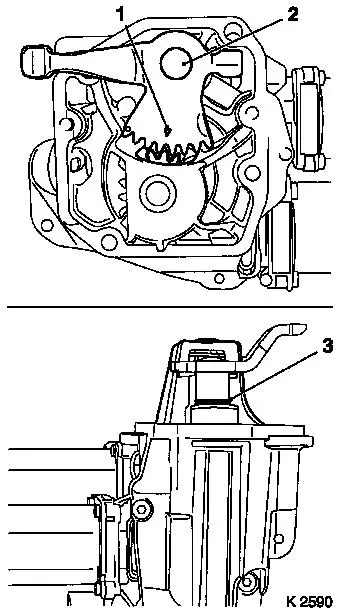

Important: The following work

step is only to be carried out up to gearshift module production

level G4D4 001 05 b. Production level is indicated by a sticker on

the gearshift module housing. From production level G4D4 001 05 c,

there is no impact marking on the toothed head of the gearshift

motor's pinion. For production levels with impact marking (e.g.

G4D4 001 03 e), the marks must align. Otherwise, fault memory

entries and system failure can be expected.

|

| 9. |

Move gearshift module to neutral position

| • |

Align the marking (1) on the gearshift lever shaft (2) with the

toothed head of the pinion, gearshift motor

|

| • |

Move gearshift lever shaft to the idling position

Note: Groove (3) is

visible and ends flush with the collared bush (removal or

as-delivered condition).

|

|

|

|

|

| 10. |

Install gearshift module

| • |

Insert gearshift module with new seal

|

| • |

Tighten 4x bolt (4) and (5) 11

Nm

Note: Use new

bolts.

|

| • |

Connect 2x wiring harness plug (1) and (2)

Note: Wiring harness

plug 1 - black (gearshift motor), wiring harness plug 2 - grey

(selector motor).

|

| • |

Attach 2x cable tie (3)

|

|

|

| 11. |

Install hydraulic modulator

|

| 12. |

Install battery support

|

| 13. |

Program volatile memories

|

| 14. |

Set transmission parameters

|

| 15. |

Comply with the start-up routines required

|

|