Oil Pump Housing Replacement (without Start/Stop System)

Special Tool

| • |

EN-662-C

Holding Wrench |

| • |

EN-46781

Fixing Tool Camshaft |

| • |

EN-46785

Fixing Tool Crankshaft |

| • |

EN-46775

Centering Tool Oil Pump Housing |

For equivalent regional tools, refer to

Special Tools .

Removal Procedure

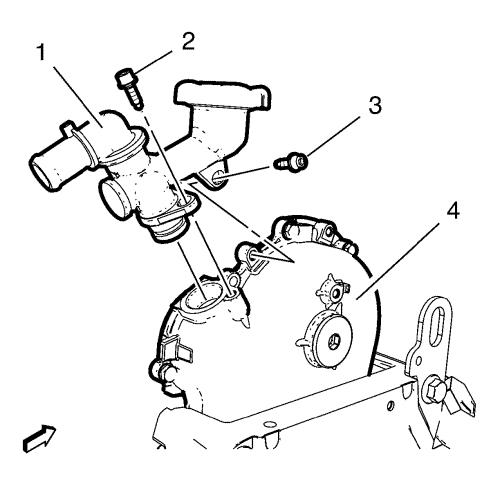

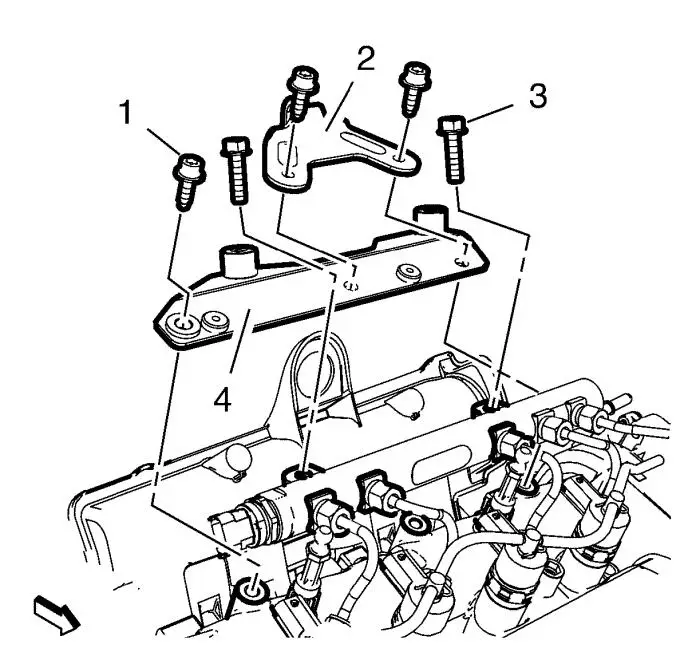

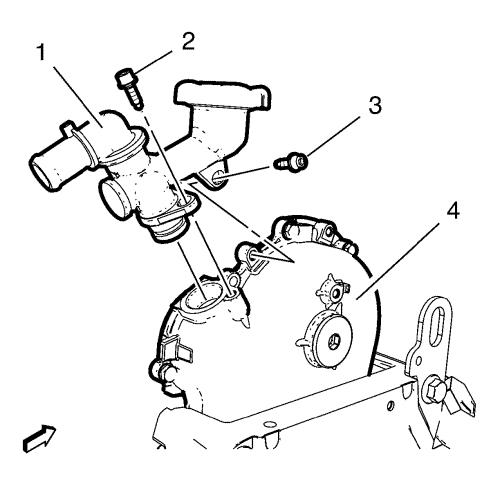

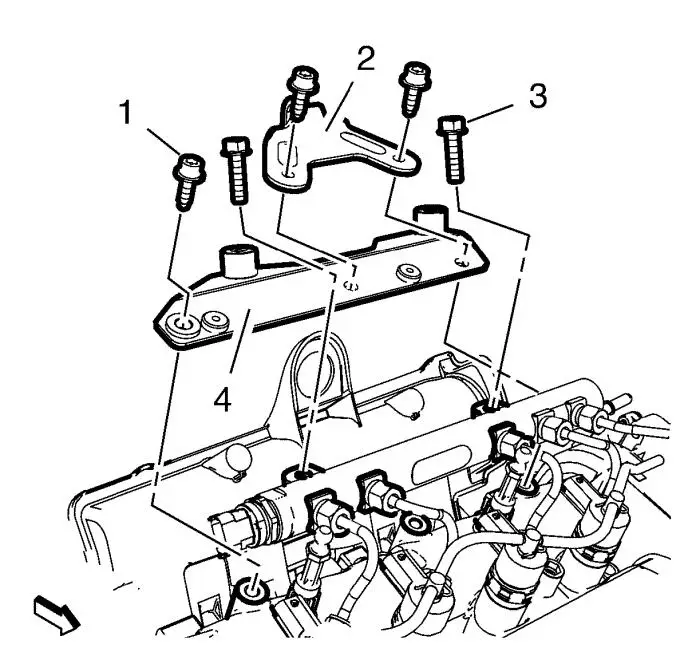

| 5. |

Remove the 2 oil filler tube

bolts (2, 3). |

| 6. |

Remove the oil filler tube (1)

from the oil pump housing (4). |

|

Note: The fuel rail

may not be subjected to the effects of any external forces after

the bracket has been removed.

|

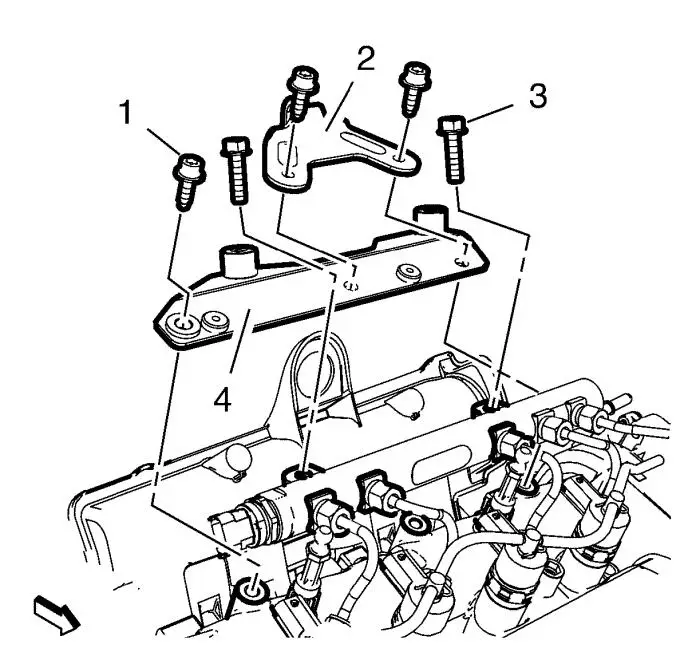

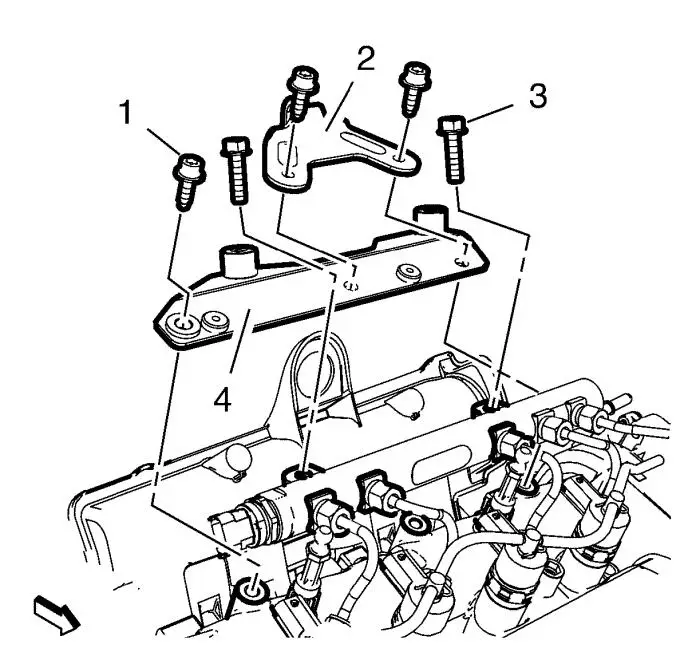

| 7. |

Remove the 2 fuel rail bolts

(1). |

| 8. |

Remove the 3 fuel rail bracket

bolts (3). |

| 9. |

Remove the fuel rail bracket

(4). |

| 10. |

Remove the engine lift bracket

(2). |

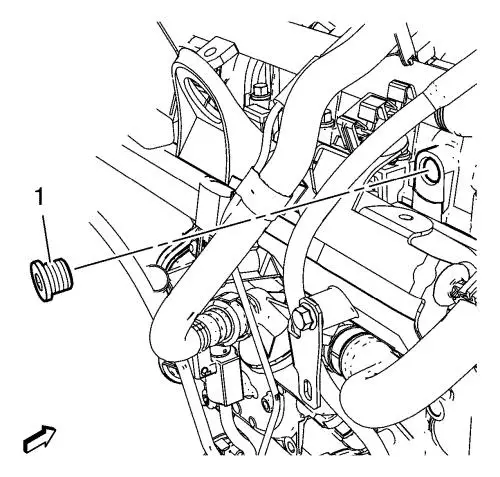

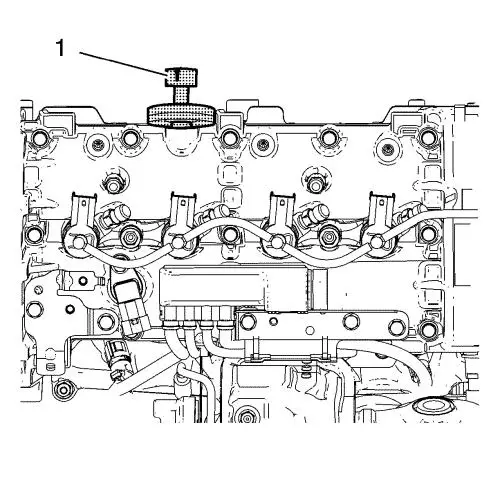

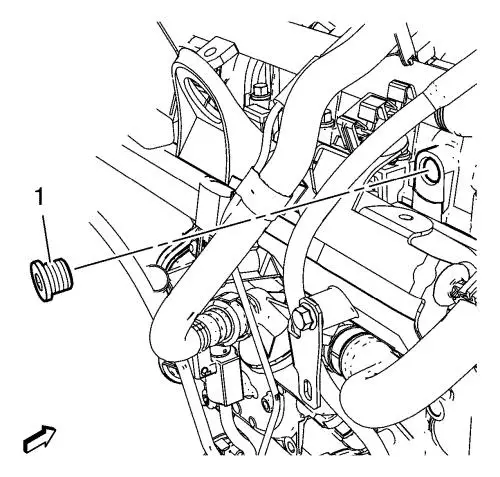

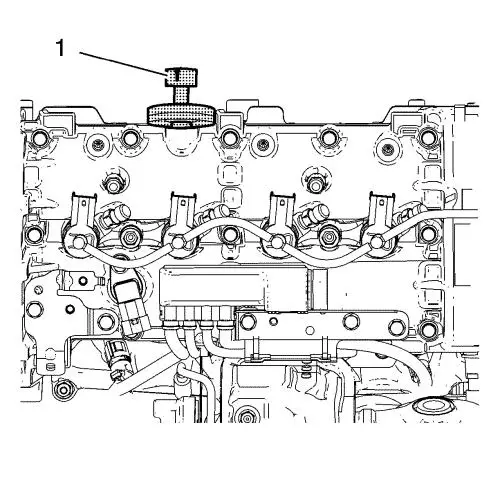

| 11. |

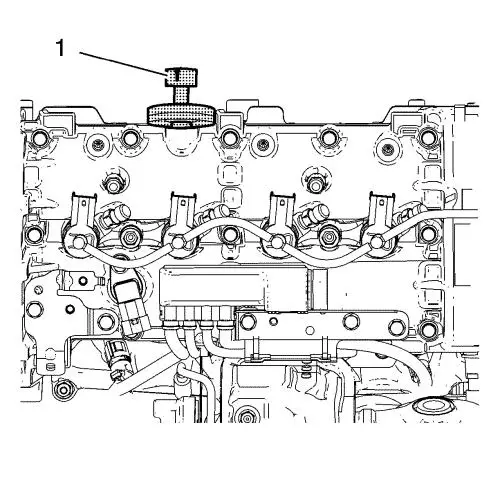

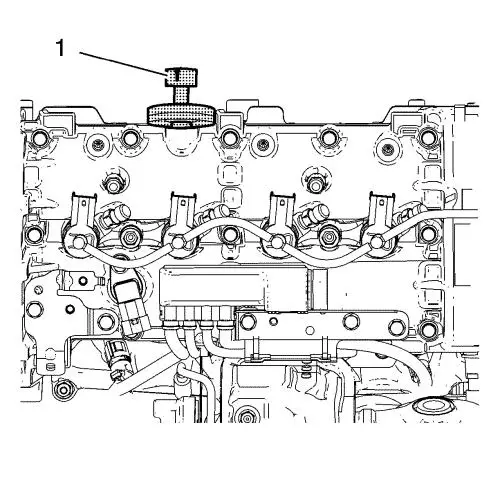

Remove the intake camshaft

housing core hole plug (1) from the camshaft housing. |

| 12. |

Clean the threads at the

camshaft housing and the camshaft housing core hole plug.

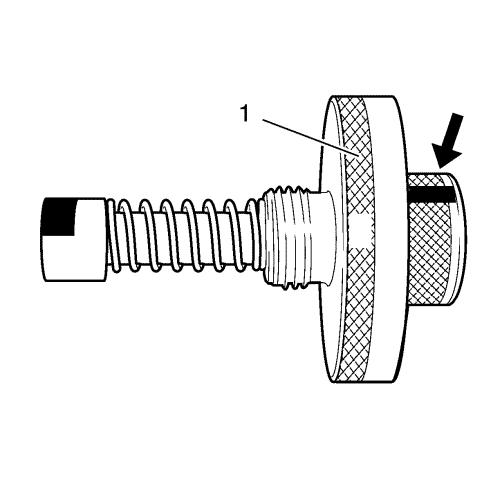

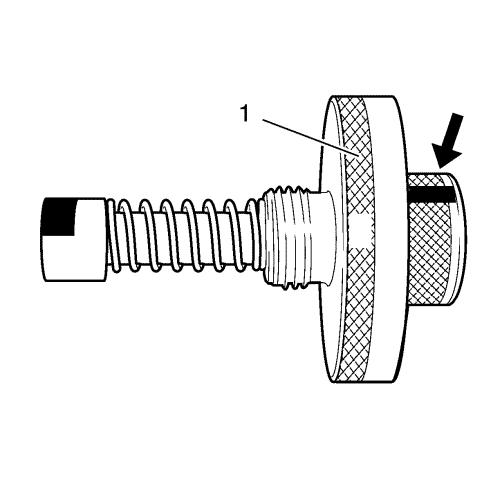

|

| 13. |

Mark (arrow) on the

EN-46781 fixing tool (1). |

|

Note: The

EN-46781 fixing tool (1) must be installed in

horizontal position.

|

| 14. |

Install the EN-46781

fixing tool (1) into the intake side. |

|

Note: If the

EN-46781 fixing tool (1) does not rotate any

longer, the tool is correctly engaged.

|

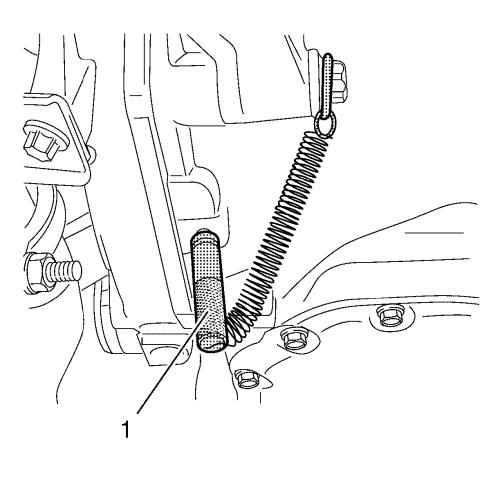

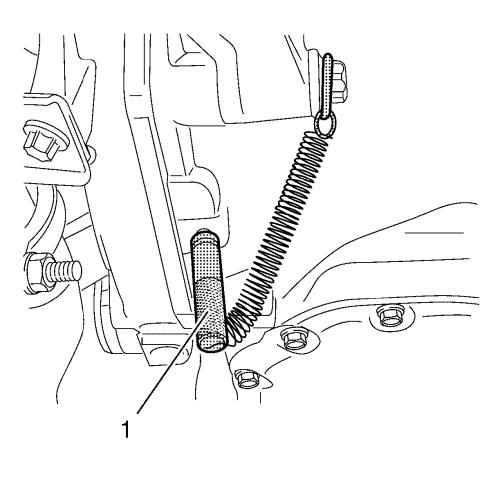

| 15. |

Turn the crankshaft at the

crankshaft sprocket bolt carefully, until the EN-46781

fixing tool (1) engages at the intake camshaft. |

|

Note: Turn the

crankshaft carefully until EN-46785 fixing tool (1)

engages in the flywheel.

|

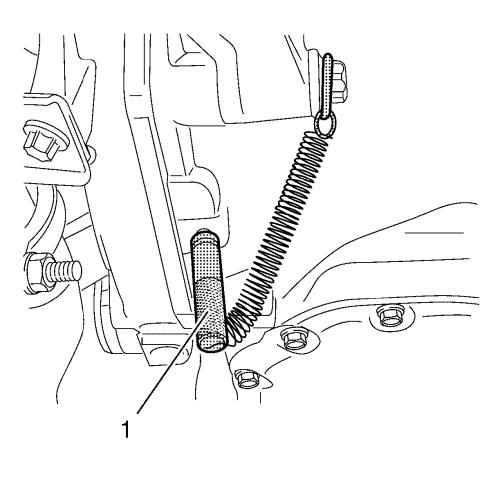

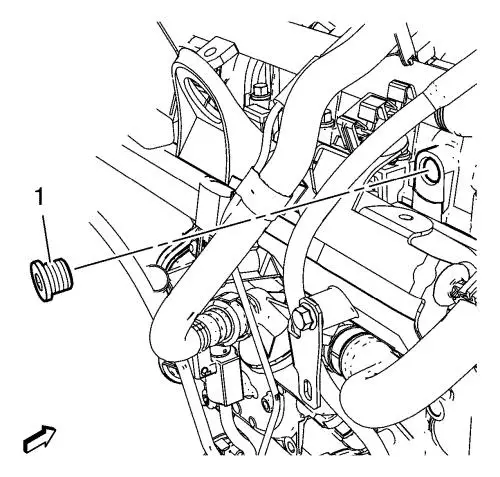

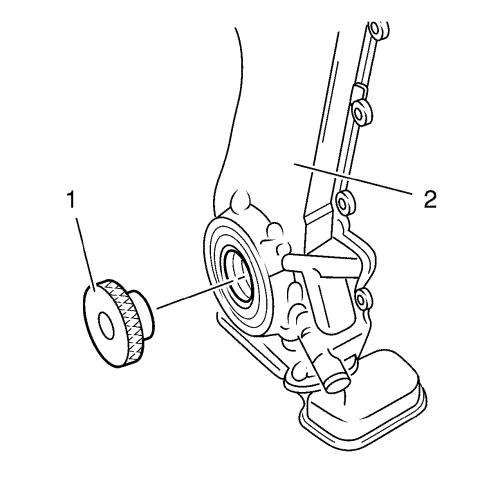

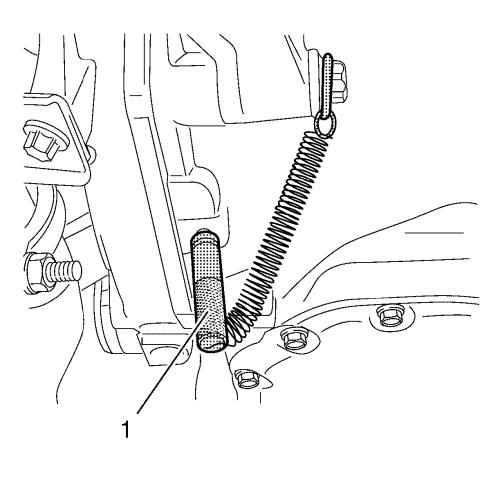

| 17. |

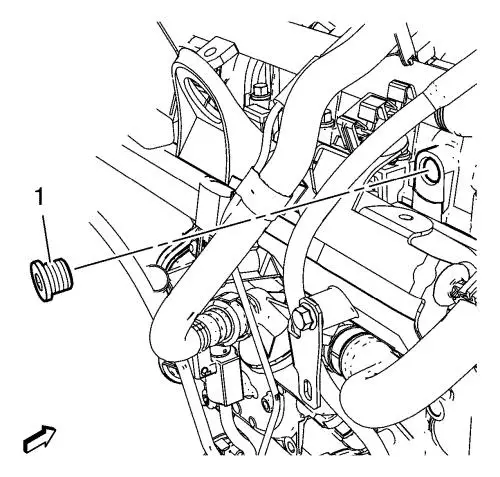

Install the EN-46785

fixing tool (1). |

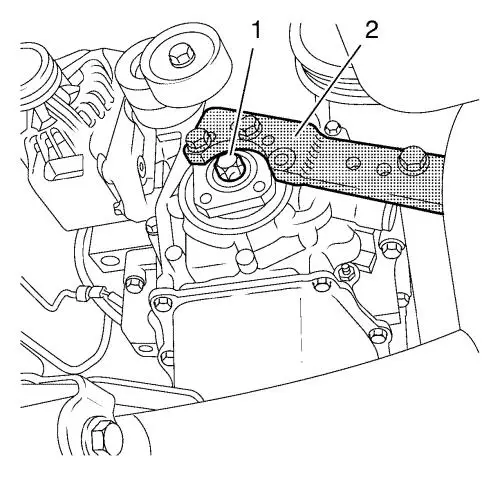

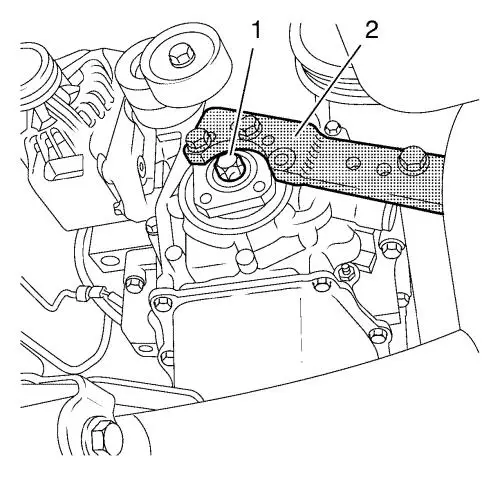

| 18. |

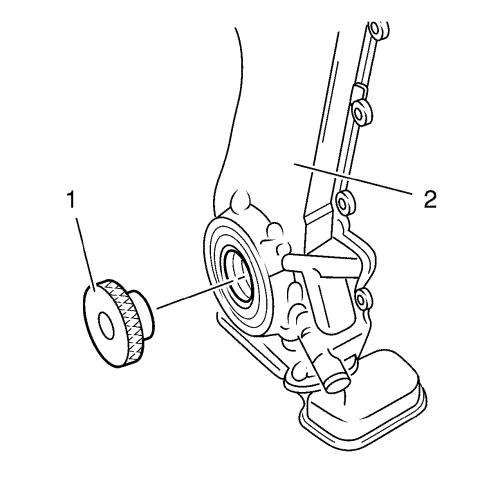

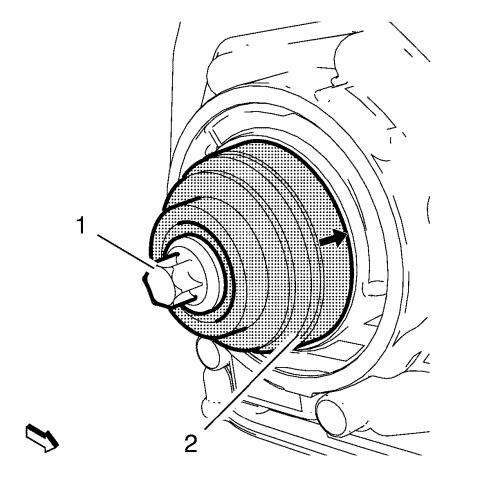

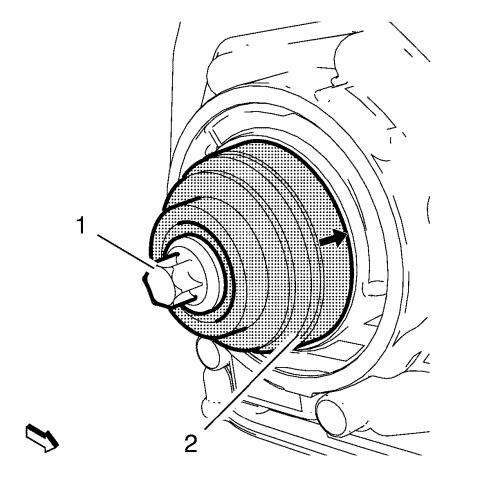

Install the EN-662-C

wrench (2). |

| 20. |

Loosen the crankshaft sprocket

bolt (1). |

|

Note: Mind the

left-hand thread.

|

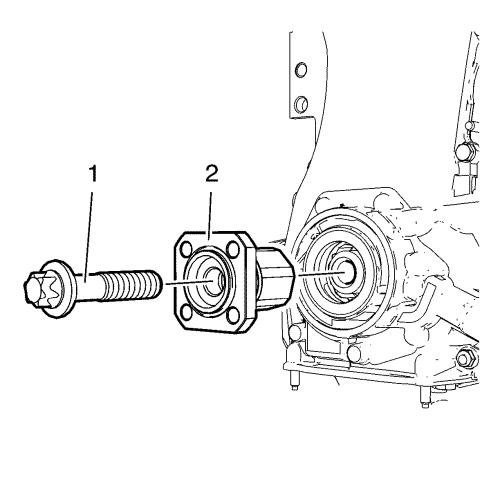

| 21. |

Remove and DISCARD the

crankshaft sprocket bolt. (1) |

| 22. |

Remove the flange (2).

|

| 23. |

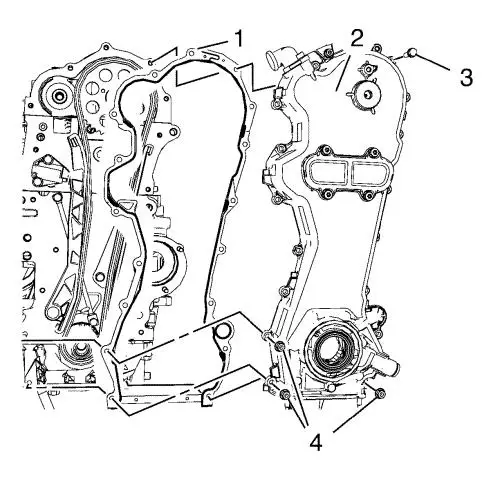

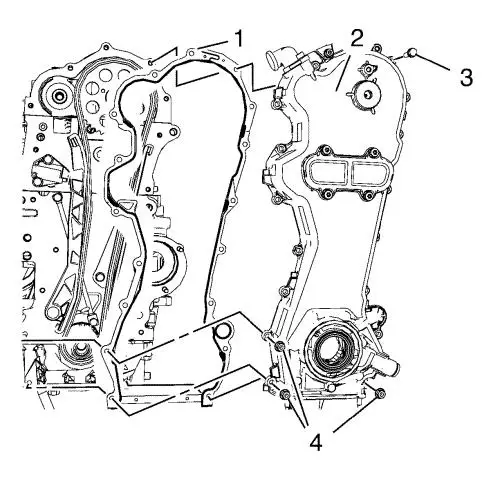

Remove the 14 oil pump housing

bolts (3). |

| 24. |

Remove the 3 oil pump housing

nuts (4). |

| 25. |

Remove the oil pump housing

(2). |

| 26. |

Remove the oil pump housing

gasket (1). |

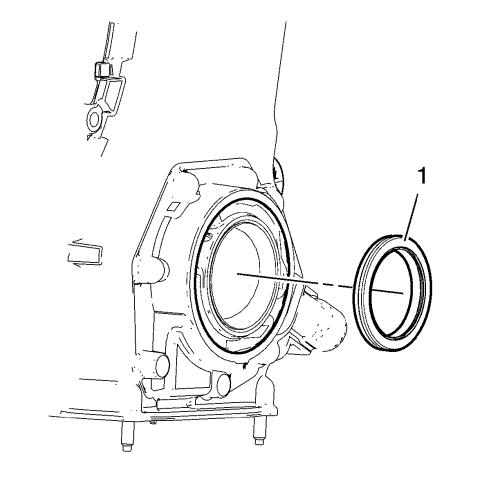

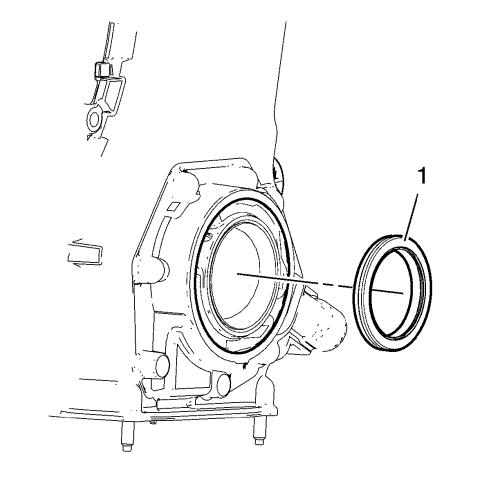

| 27. |

Remove the oil pump seal

(1). |

Installation Procedure

| 1. |

Ensure that EN-46781

fixing tool and EN-46785 fixing tool are

already installed. |

|

Note: The oil pump

housing must be fitted within 10 minutes of applying the silicone

sealing compound.

|

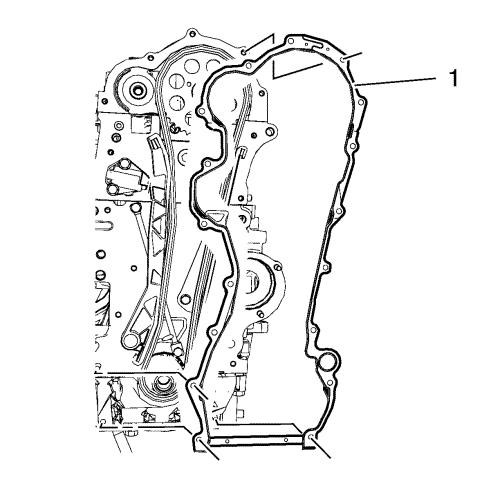

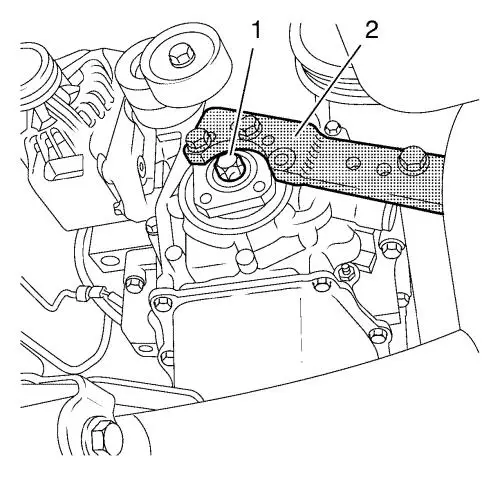

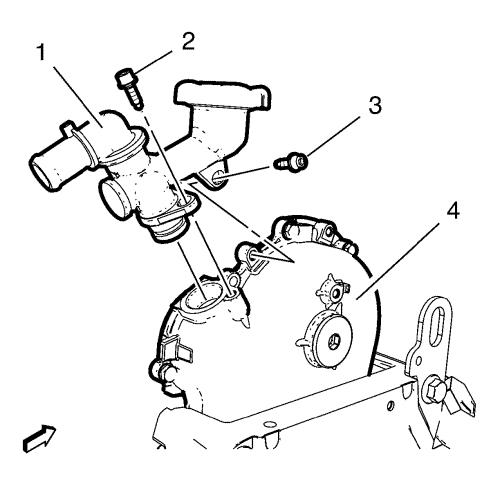

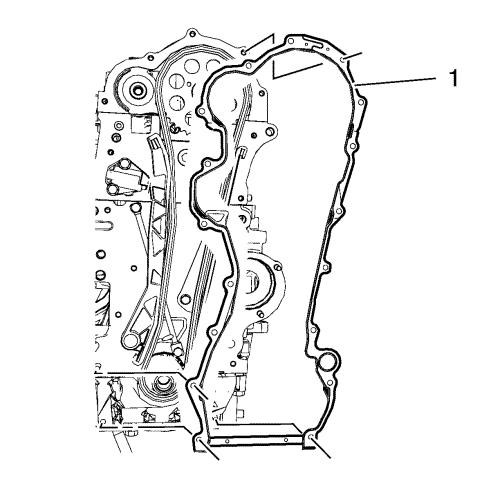

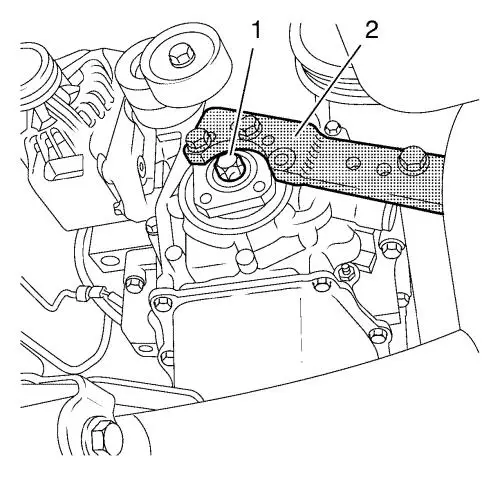

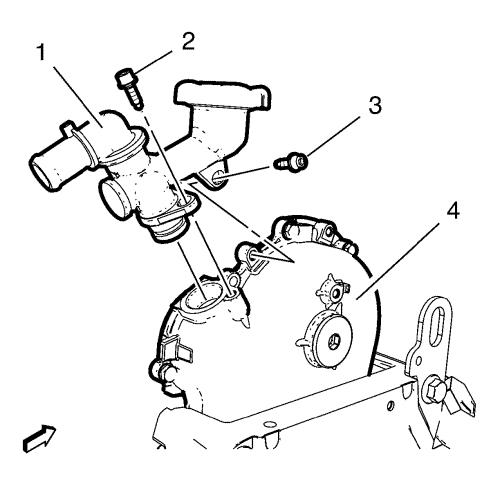

| 2. |

Apply silicone sealing

compound to the transitions between the cylinder head and camshaft

housing (1) and between the cylinder block and cylinder head

(2). |

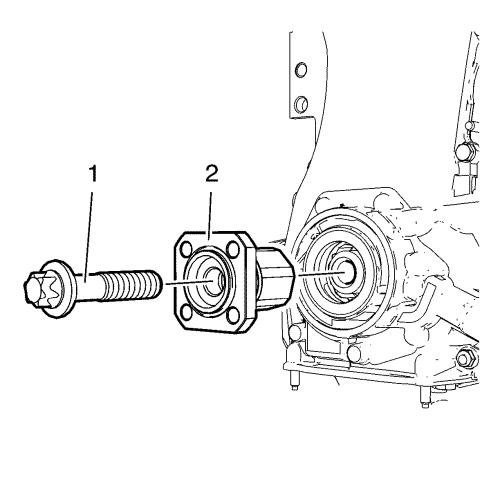

| 3. |

Install the oil pump housing

gasket (1). |

| 4. |

Install the oil pump housing

(2) with the EN-46775 fixing tool (1). |

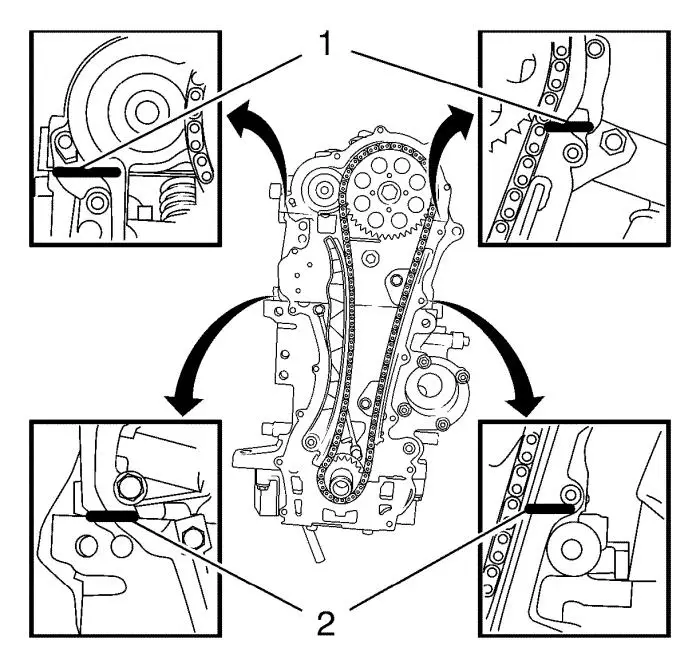

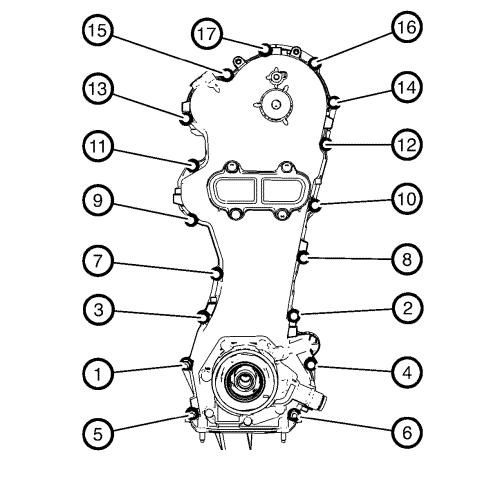

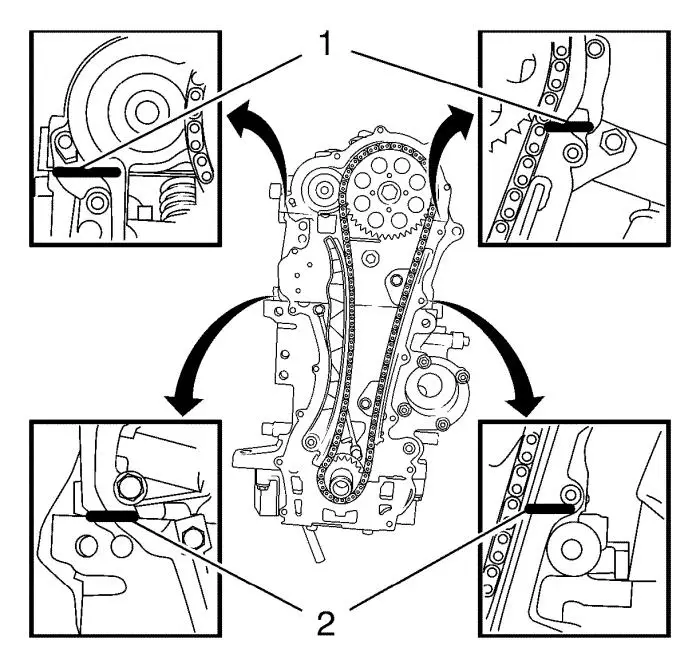

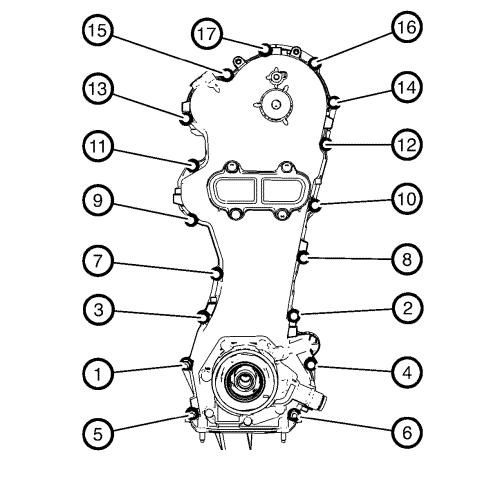

| 5. |

Tighten the 14 oil pump

housing bolts and the 3 oil pump housing nuts in sequence as

shown: |

| |

• |

In first step and in sequence

as shown, tighten to 4 N·m (35 lb in)

. |

| |

• |

In second step and in sequence

as shown, tighten to 9 N·m (80 lb in)

. |

| |

• |

Remove the EN-46775

fixing tool . |

|

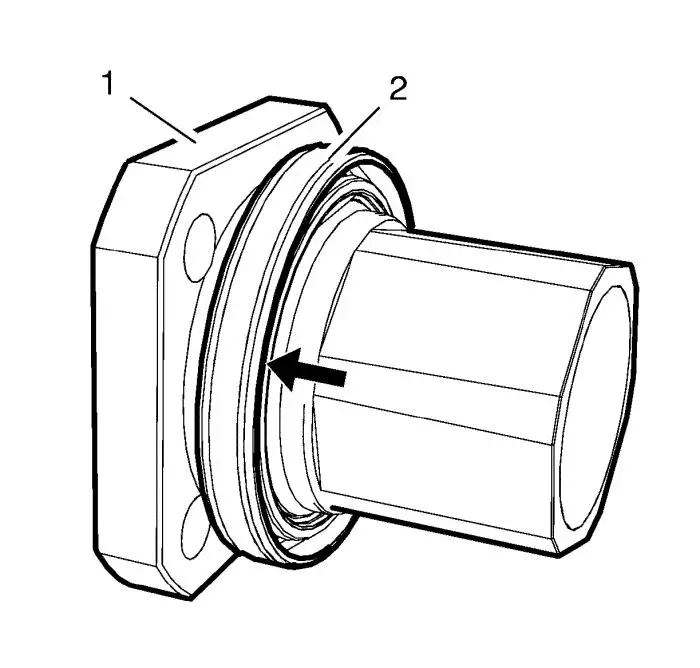

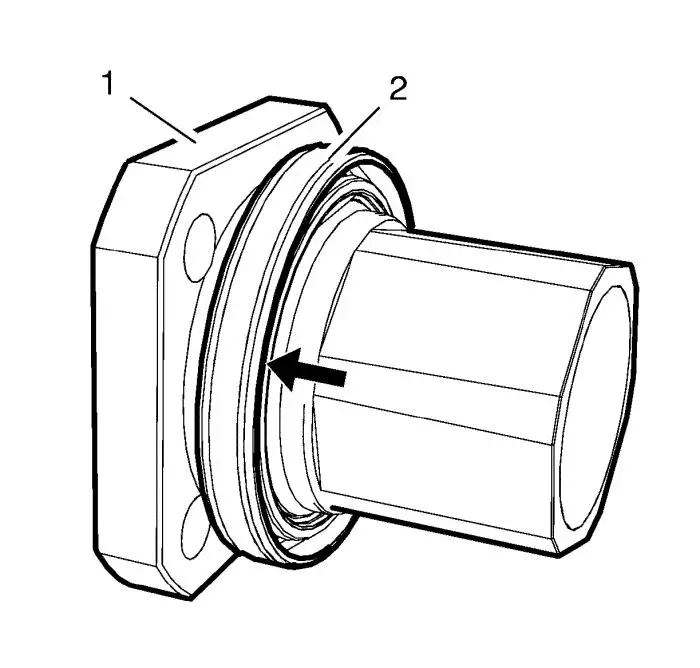

Note: Slide the oil

pump seal over the flange sealing the surface (arrow).

|

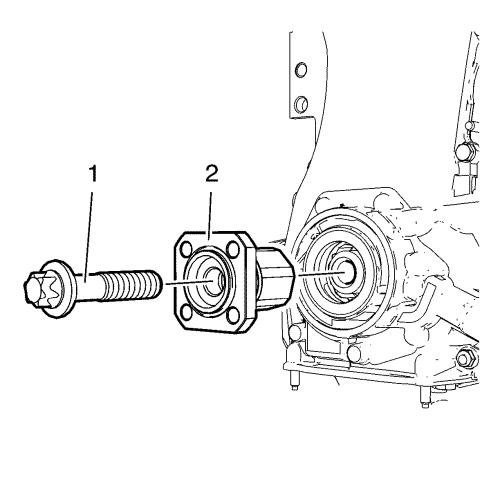

| 6. |

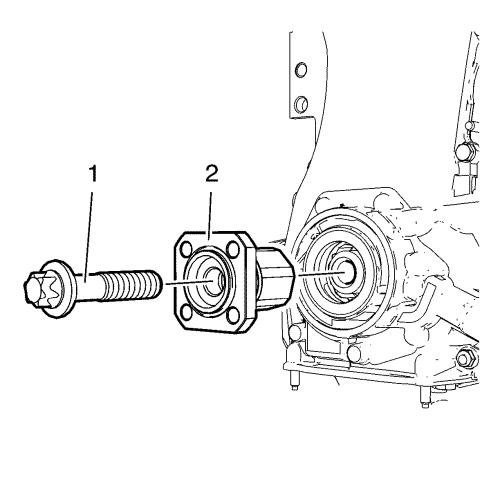

Install the oil pump seal (2)

to the flange (1). |

| 7. |

Position the flange (2) with

the oil pump seal (3) to the crankshaft. |

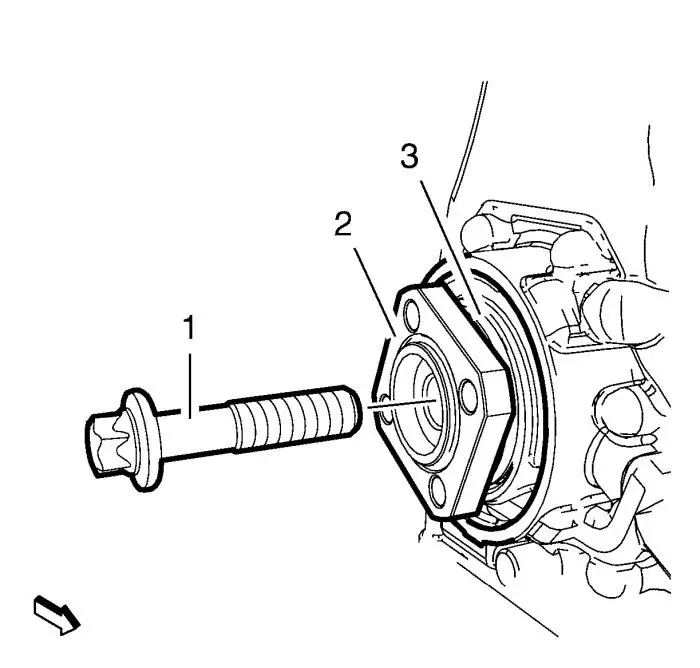

| 8. |

Tighten carefully the flange

bolt (1) to limit stop. |

| 9. |

Remove the flange bolt

(1). |

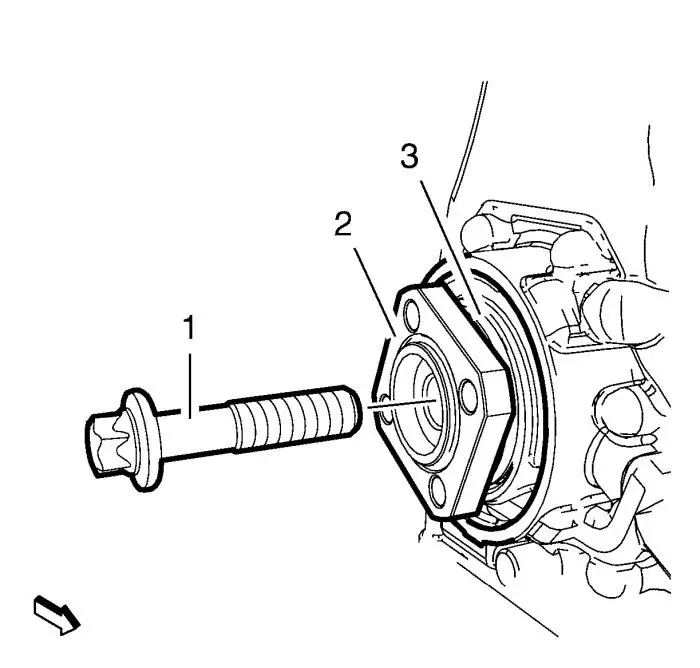

| 10. |

Remove the flange (2).

|

| 11. |

Position EN-46775

centering tool (2) with the plane surface at the oil pump

housing. |

| 12. |

Tighten carefully the flange

bolt (1) until the EN-46775 centring tool is flush

with oil pump housing (arrow). |

| 13. |

Remove the flange bolt and the

EN-46775 centring tool . |

| 14. |

Install the flange (2).

|

| 15. |

Loosely install the NEW

crankshaft sprocket bolt (1). |

| 16. |

Install the EN-662-C

wrench (2). |

|

Note: Mind the

left-hand thread.

|

| 18. |

Tighten the crankshaft

sprocket bolt (1) to 50 N·m (37 lb ft)

. |

| 19. |

Tighten the crankshaft

sprocket bolt to additional 90° . Use the

EN-470-B wrench . |

| 20. |

Remove the EN-46785

fixing tool (1). |

| 22. |

Remove the EN-46781

fixing tool (1) from the intake side. |

| 24. |

Install the intake camshaft

housing core hole plug (1) to the camshaft housing and tighten to

15 N·m (11 lb ft) . |

|

Note: The fuel rail

may not be subjected to the effects of any external forces after

the bracket has been removed.

|

| 25. |

Install the engine lift

bracket (2). |

| 26. |

Install the fuel rail bracket

(4). |

| 27. |

Install the 3 fuel rail

bracket bolts (3) and tighten to 25 N·m (18 lb

ft) . |

| 28. |

Install the 2 fuel rail bolts

(1) and tighten to 25 N·m (18 lb ft)

. |

| 29. |

Install the oil filler tube

(1) to the oil pump housing (4). |

| 30. |

Install the 2 oil filler tube

bolts (2, 3) and tighten to 9 N·m (80 lb

in) . |

|