Crankshaft and Bearing Cleaning and Inspection

Special Tools

| • |

EN-470-B

Angular Torque Wrench |

For equivalent regional tools, refer to

Special Tools .

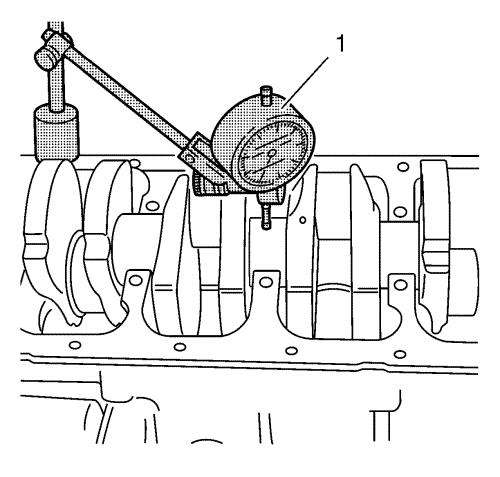

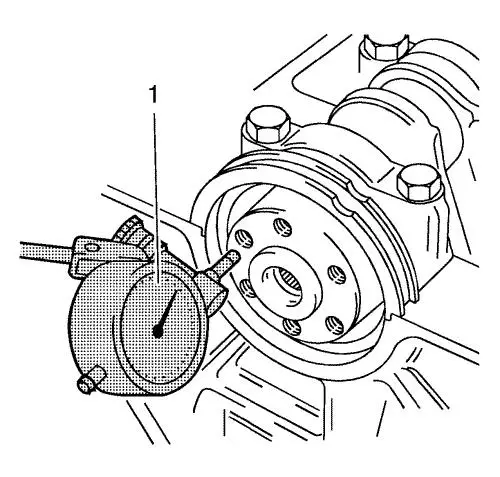

Crankshaft End Play, Check

|

Note: Crankshaft

attached with crankshaft bearing caps.

|

| 1. |

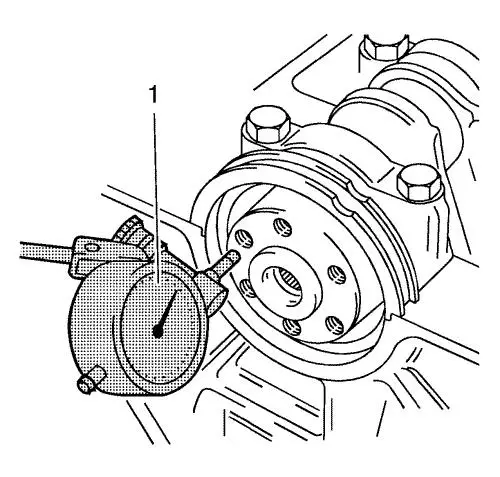

Install the GE-571-B

gauge (1). |

| |

• |

Install the holder on the

front of the engine block. |

| |

• |

Place the dial gauge plunger

against the crankshaft and adjust. |

| 2. |

Measure the longitudinal play

of the crankshaft. |

| |

• |

Move the crankshaft in the

longitudinal direction. |

| |

• |

Permissible crankshaft end

play 0.100-0.202 mm (0.0039-0.0080 in) .

|

| 3. |

Remove the GE-571-B

gauge . |

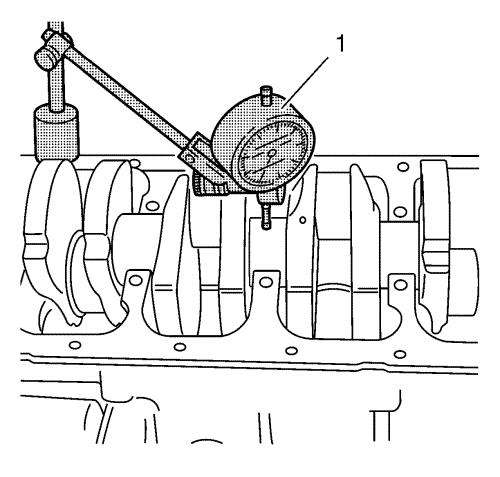

Crankshaft Out-of-Round, Check

|

Note: Crankshaft

removed.

|

| 1. |

Insert the crankshaft in the

engine block. |

| 2. |

Install the GE-571-B

gauge (1). |

| |

• |

Attach holder to the engine

block. |

| |

• |

Place the dial gauge plunger

against the crankshaft bearing journal and adjust. |

| 3. |

Check the rotational play of

the crankshaft. |

| |

• |

Turn the crankshaft

evenly. |

| |

• |

Maximum permissible rotational

play 0.03 mm (0.001 in) . |

| 4. |

Remove the GE-571-B

gauge . |

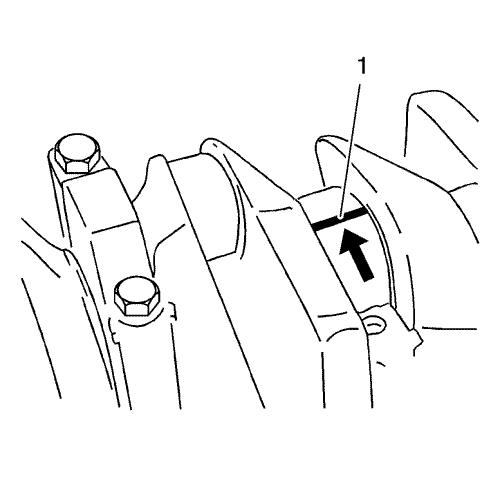

Check Crankshaft Bearing Clearance (With Plastigage)

|

Note:

| • |

Do not rotate the

crankshaft. |

|

| |

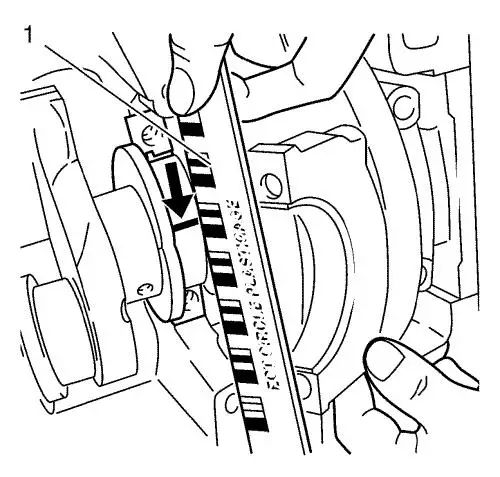

Lay out plastigage (flexible plastic thread) around the entire

width of the crankshaft bearing journal (1). |

|

Note: The bolts can

be reused for checking the crankshaft bearing play.

|

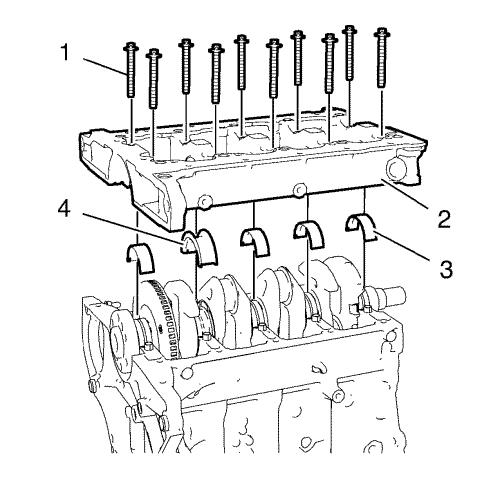

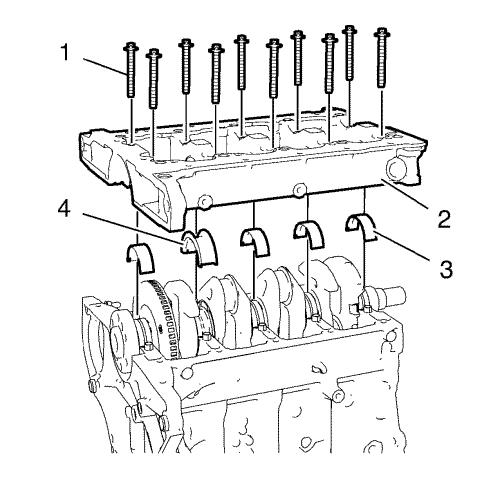

| 2. |

Install the 4 lower crankshaft

bearings (3) and the lower crankshaft thrust bearing (4).

|

| 3. |

Install the crankshaft bearing

cap tie plate (2). |

| 4. |

Install the 10 inner

crankshaft bearing cap tie plate bolts (1). |

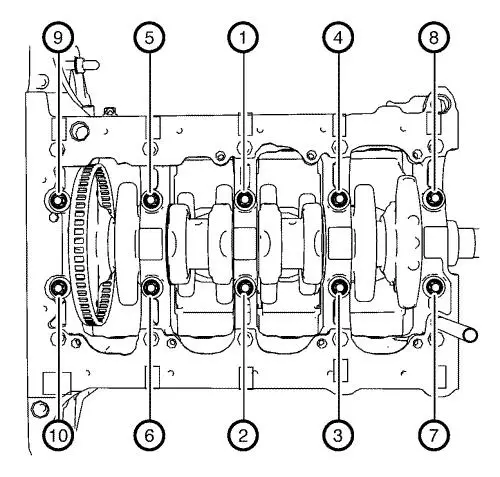

| 5. |

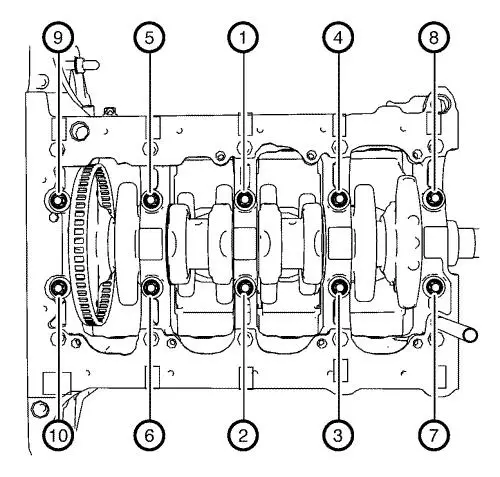

Tighten the 10 inner

crankshaft bearing cap tie plate bolts in a sequence as shown and

in the following order: |

| |

5.1 |

Tighten the inner crankshaft

bearing cap tie plate bolts to 25 N·m (18 lb

ft) . |

| |

5.2 |

Tighten the inner crankshaft

bearing cap tie plate bolts an additional 60°

. Use EN-470-B wrench . |

| |

5.3 |

Tighten the inner crankshaft

bearing cap tie plate bolts an additional 15°

. Use EN-470-B wrench . |

| 6. |

Remove the crankshaft bearing

cap tie plate bolts and the crankshaft bearing cap tie

plate. |

|

Note: When reading

the value, do not confuse millimeters and inches on the measuring

scale.

|

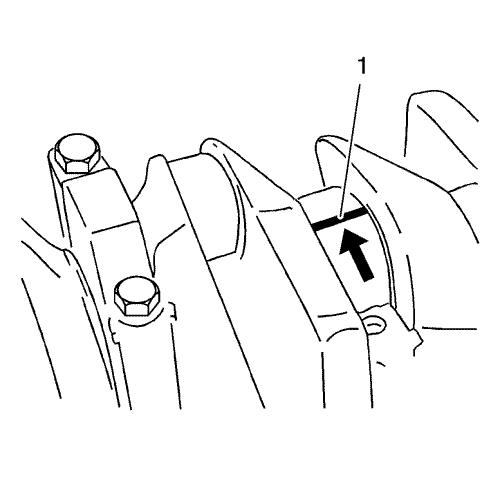

| 7. |

Measure the crankshaft bearing

play. |

| |

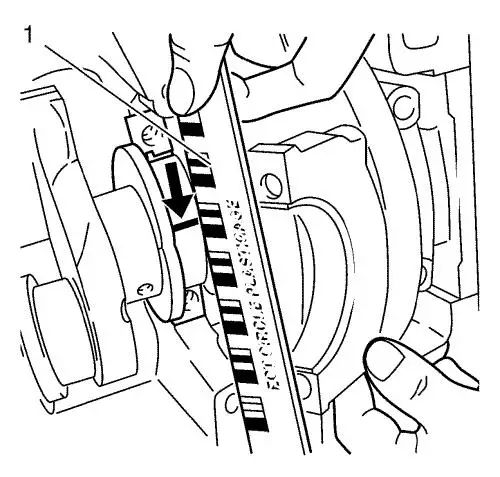

• |

Compare the width of the

flattened plastic thread (arrow) to the measuring scale (1).

|

| |

• |

The crankshaft bearing play

should be 0.007-0.031 mm (0.00028-0.00122 in)

. |

Check Crankshaft Bearing Clearance (With Micrometer Gauge

Internal Measuring Device)

|

Note: The bolts can

be reused for checking the crankshaft bearing play.

|

| 1. |

Install and tighten the

crankshaft bearing cap tie plate and the crankshaft bearings as

shown above. |

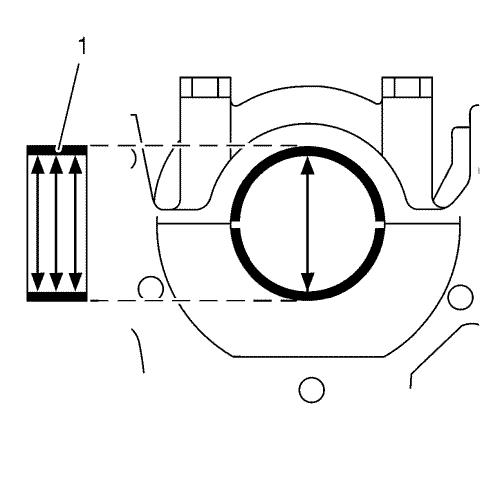

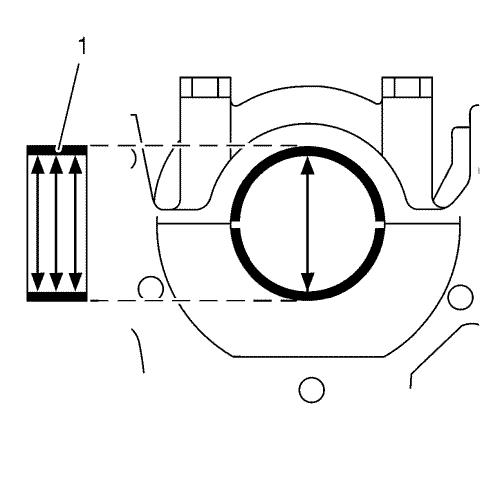

| 2. |

Measure the crankshaft bearing

diameter at 3 points. |

| |

Measure in areas as shown (1) with an internal measuring

device. |

| |

Calculate the average crankshaft bearing diameter. |

| |

Formula: 1. result + 2. result + 3. result / 3. |

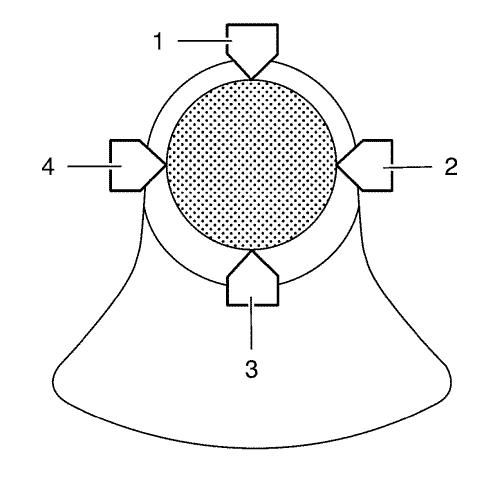

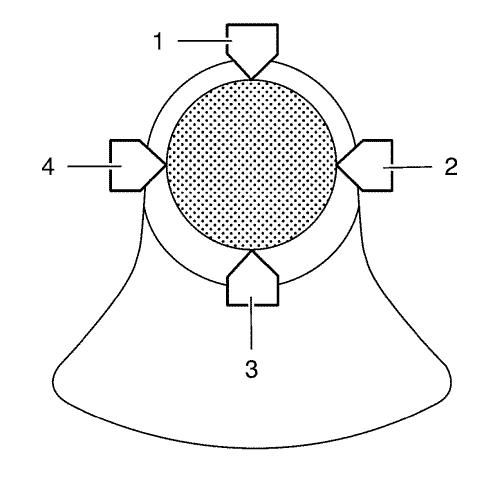

| 3. |

Measure the crankshaft bearing

journal diameter at 2 points between (1) and (3) and between (2)

and (4) with the micrometer gauge. |

| 4. |

Calculate the average

crankshaft bearing journal diameter. |

| |

Formula: 1. result + 2. result / 2. |

| 5. |

Determine the crankshaft

bearing play. |

| |

Calculation formula: average crankshaft bearing diameter minus

average crankshaft bearing journal diameter. |

| 6. |

The crankshaft bearing play

should be 0.007-0.031 mm (0.00028-0.00122 in)

. |

|