Oil Pan Replacement

Special Tools

EN-37228 Separation Tool

For equivalent regional tools, refer to

Special Tools .

Removal Procedure

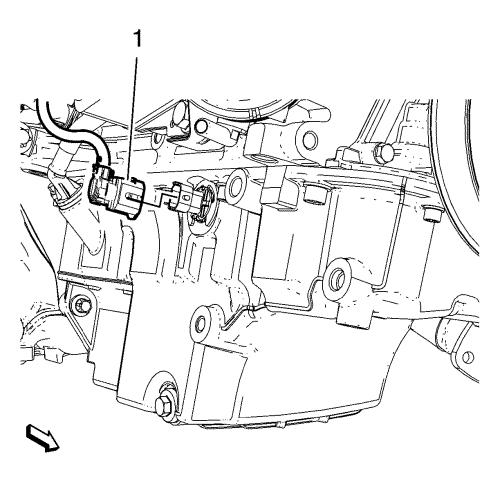

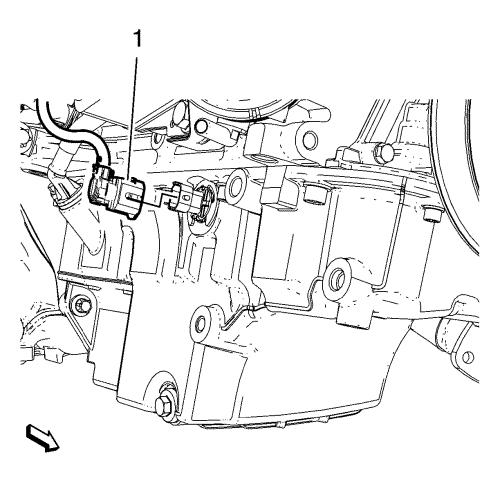

| 8. |

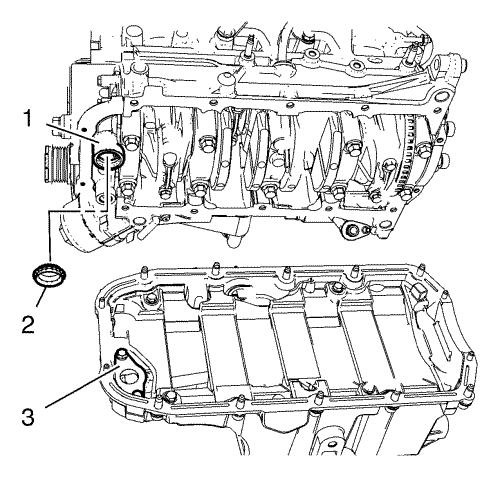

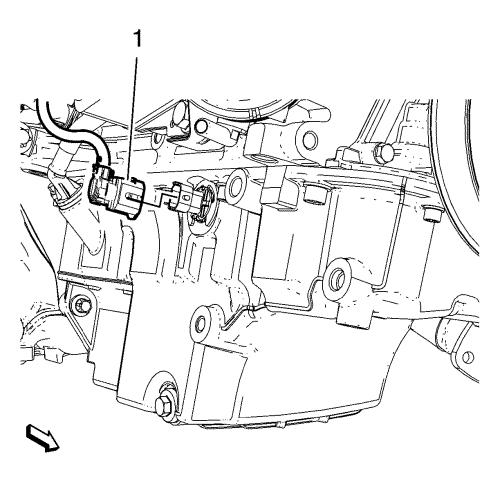

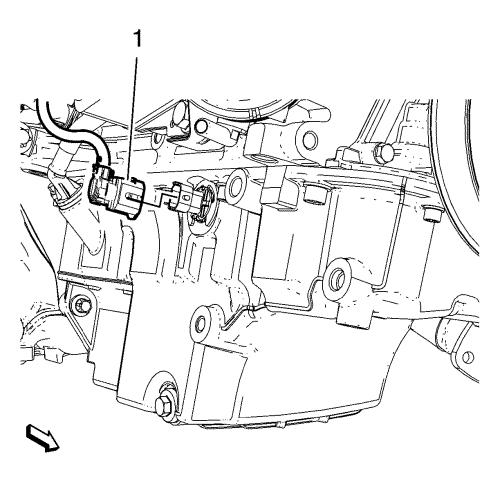

Disconnect the engine oil

level sensor wiring harness plug (1). |

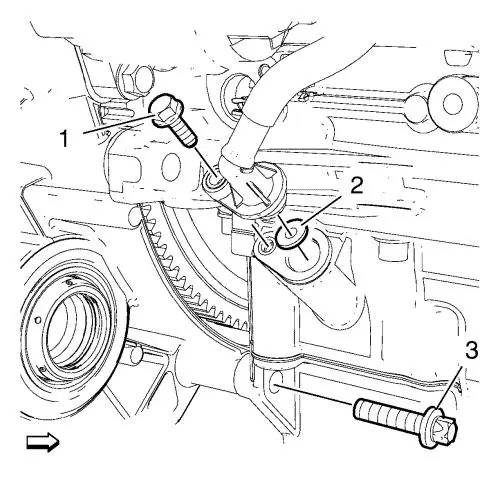

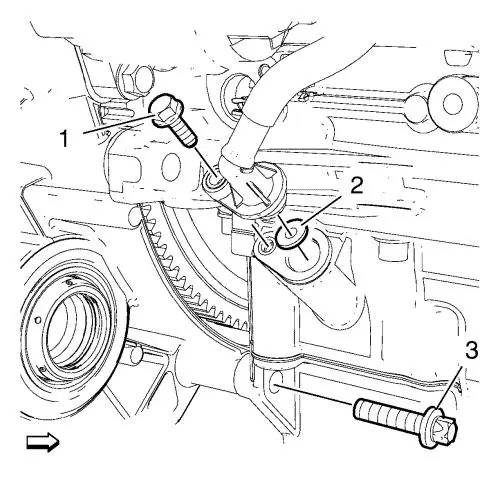

| 9. |

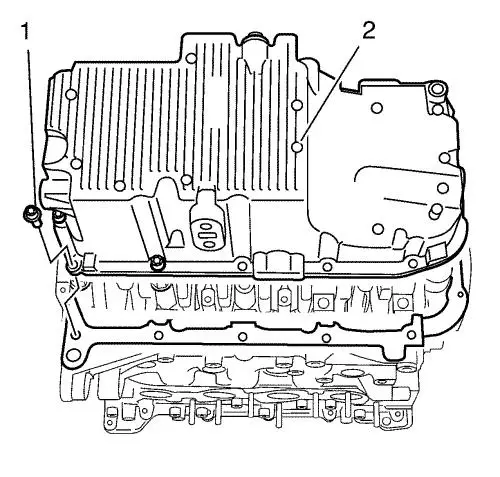

Remove the positive crankcase

ventilation tube bolt (1) and hang the tube aside. |

| 10. |

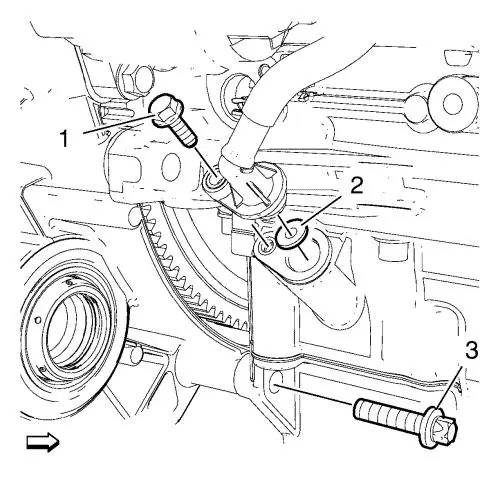

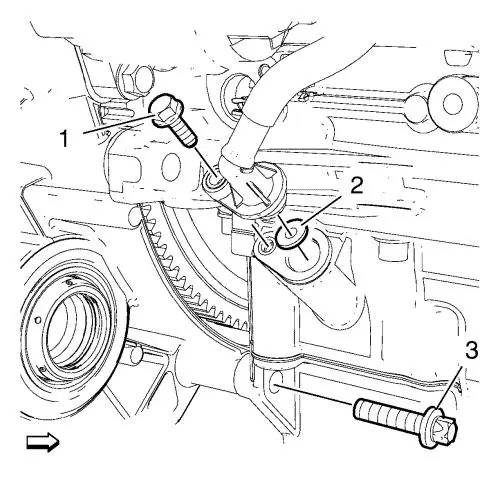

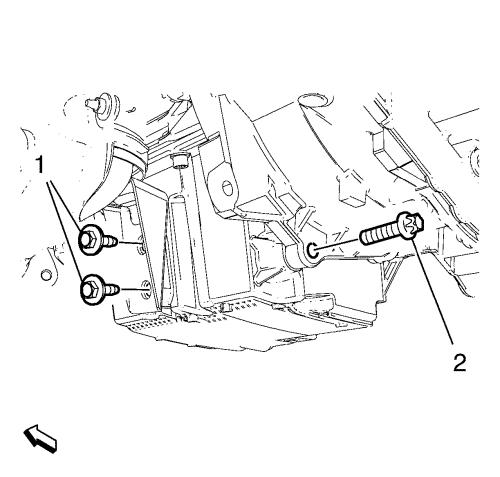

Remove the transmission bolt

(3). |

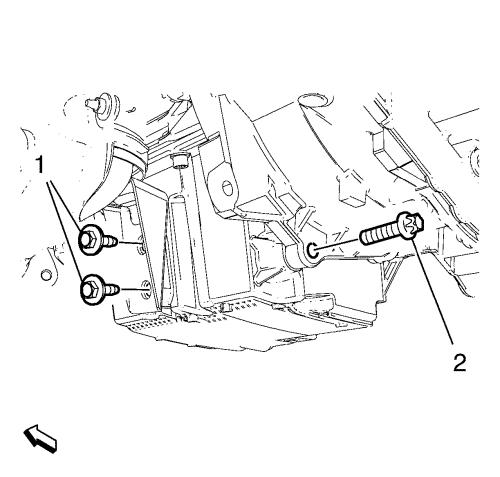

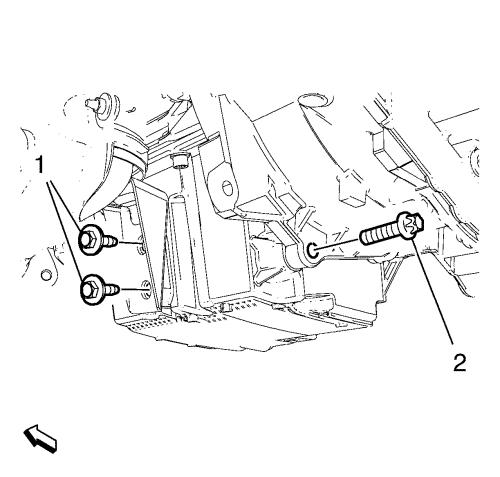

| 11. |

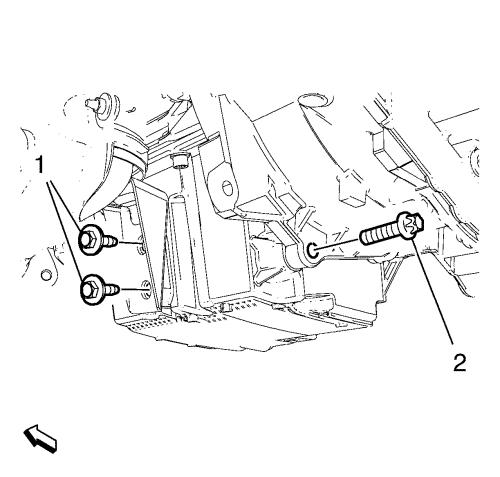

Remove the 2 catalytic

converter brace bracket bolts (1). |

| 12. |

Remove the transmission bolt

(2). |

|

Note: Mark the

positions of the oil pan bolts, because of different length.

|

|

Note: Use a suitable

tool.

|

|

Note: Be carefully DO

NOT damage the oil pan or the oil pan sealing surface.

|

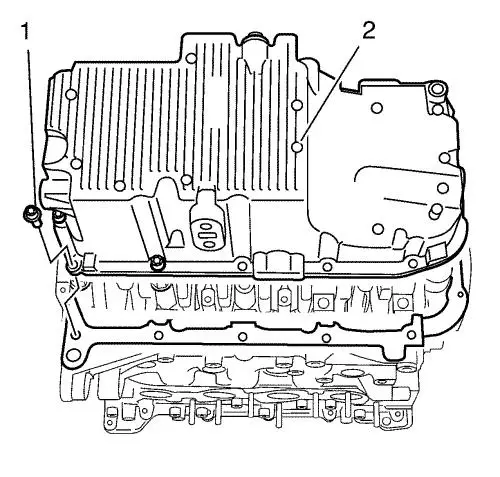

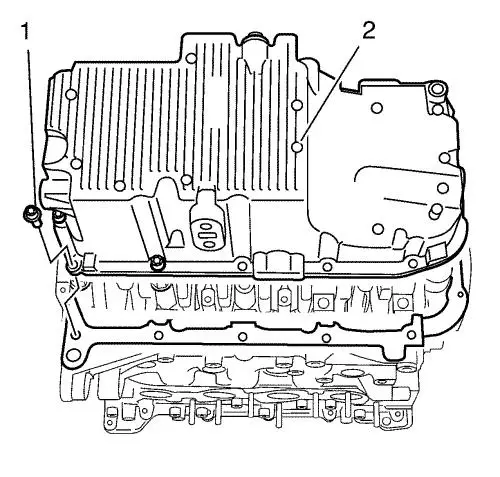

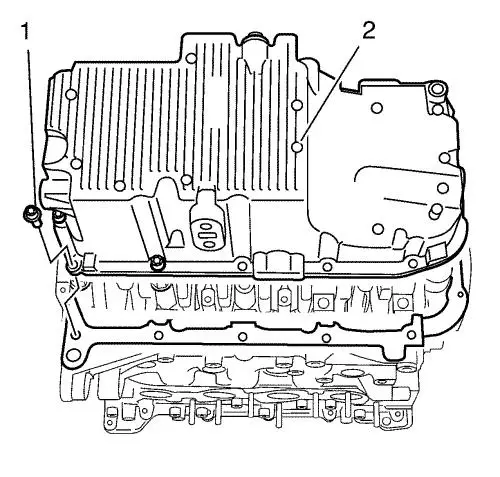

| 13. |

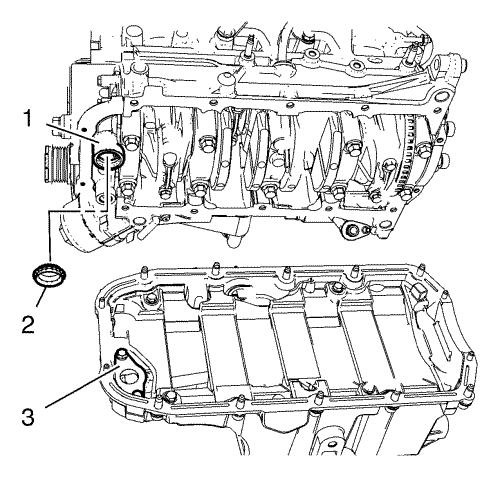

Remove the 12 bolts

(1). |

| 14. |

Turn the engine to get access

to the remaining 2 oil pan bolts through the opening in the

flywheel. |

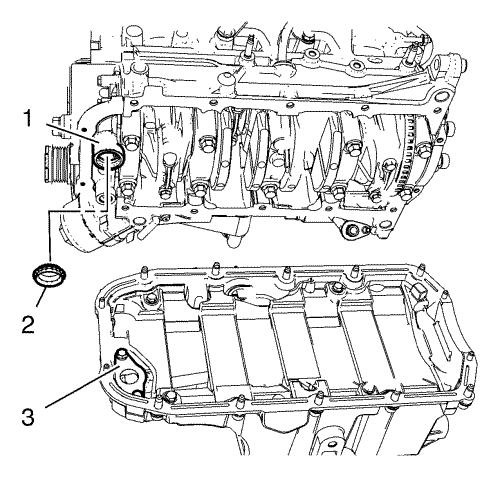

| 15. |

Remove the oil sump (2) by

using the EN-37228 separating tool . |

| 16. |

Remove the oil pump sealing

(2) from the oil pump (1). |

Installation Procedure

| 2. |

Install a NEW oil pump sealing

(2) to the oil pump (1). |

|

Note: Ensure that the

oil pan sealing surfaces are clear of oil, grease and oil gasket

material.

|

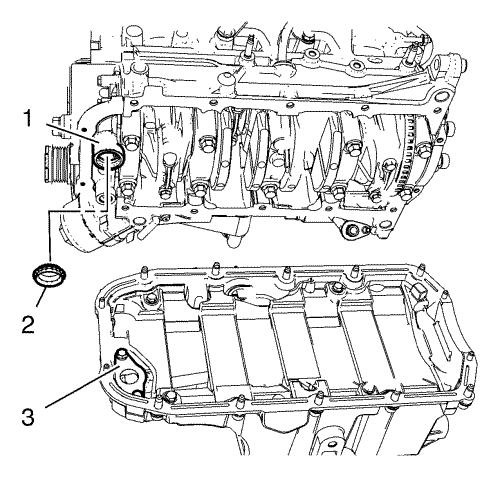

| 3. |

Clean the sealing surface from

oil pump suction pipe (3). |

| 4. |

Clean the oil pan sealing

surface. |

|

Note: DO NOT coat

sealant on the oil sump bolt holes, it could damage the oil sump

bolt threads or the engine block.

|

|

Note: Refer to

electronic parts catalogue to find a suitable sealing compound.

|

| 5. |

Coat the oil pan sealing

surface with suitable sealing compound. The thickness of the

sealing bead should be 2 mm (0.0787 in) .

|

|

Note: The

installation procedure should be done in 10 minutes.

|

| 6. |

Install the oil pan

(2). |

| 7. |

Install the 10 M8 bolts and

tighten to 25 N·m (18 lb ft) . |

| 8. |

Install the 4 M6 bolts and

tighten to 9 N·m (80 lb in) . |

| 9. |

Install the 2 catalytic

converter brace bracket bolts (1) and tighten to 20

N·m (15 lb ft) . |

| 10. |

Install the transmission bolt

(2) and tighten to 40 N·m (30 lb ft)

. |

| 11. |

Install a NEW seal ring (2) to

the positive crankcase ventilation tube. |

| 12. |

Install the positive crankcase

ventilation tube bolt (1) and tighten to 9 N·m (80

lb in) . |

| 13. |

Install the transmission bolt

(3) and tighten to 40 N·m (30 lb ft)

. |

| 14. |

Connect the engine oil level

sensor wiring harness plug (1). |

|