Corsa C

|

Multijet system - Z 13 DT DOHC diesel engine The Z 13 DT engine has a multijet system, a further enhancement of the "Common Rail" principle whereby the injectors are electronically controlled and in each engine cycle perform not two as before, but several injection operations. The quantity of fuel burned in the cylinder is the same, but is divided up into several parts and thereby burned more uniformly and more efficiently. The advantage of the multijet multiple injection system is the interaction between control unit and injectors which can perform a sequence of injection operations over a very short period of time. This new injection process guarantees more accurate control of the pressure and temperature conditions in the combustion chamber and better utilisation of the air in the cylinders. The principle on which the development of the multijet process was based is simple: Current Common Rail engines already use a pilot injection process which increases the temperature and pressure in the cylinder, thus ensuring a more uniform combustion and thereby less combustion noise. By sub-dividing the main injection process into several smaller injection operations, it was possible to achieve positive results in terms of combustion noise control, reduction of exhaust emissions and increase in performance.

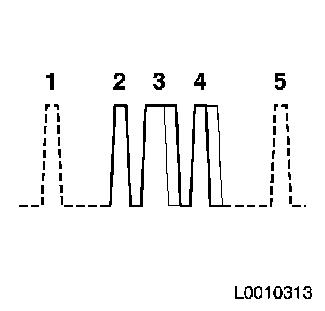

Injection sequence Pilot injection In the pilot injection process a small quantity of diesel fuel is injected into the cylinder which improves the efficiency of the combustion process and achieves the following effects:

Main injection The main injection process is sub-divided into up to three smaller injection processes. During operation, the "MM 6JF" engine management system continually adjusts the injection map, the number of injection processes and the quantity of diesel injected. By sub-dividing the main injection process, additional positive results can be achieved:

Secondary injection The secondary injection process is used to add in the fuel and follows the main injection process. It occurs in the exhaust stroke. In contrast to pilot and main injection, the fuel is not burned; instead, it is vaporised by the residual heat in the exhaust gas and in the exhaust stroke is led via the exhaust valves to the exhaust system. Some of the fuel is fed back in via the exhaust gas recirculation system for combustion, thus acting like a very early pilot injection process. |

||||||||||||||||||||||||||||||||||