|

J456600 Oil Pump, Remove and Install (Y 17 DTL,

without AC, LHD)

Note: KM-6394 must be used from model year 04 instead of

KM-6169-1 .

|

1. Open bonnet

|

|

Caution!

On vehicles from model year 04 with ESP - the steering angle

sensor loses its basic adjustment each time the battery is

disconnected. It must be recalibrated.

2. Disconnect battery

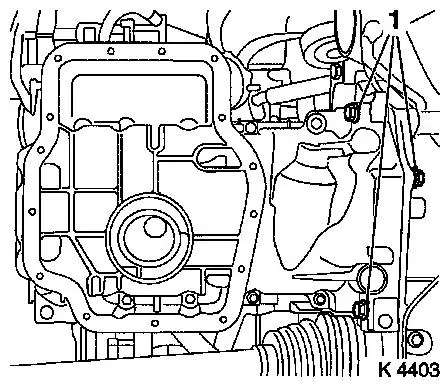

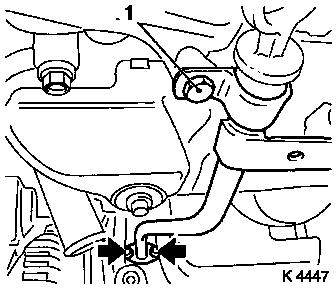

3. Remove oil filter element

- Place collecting basin underneath.

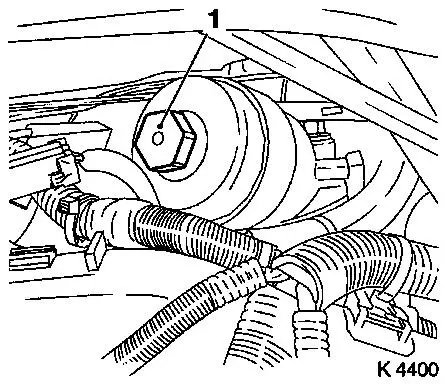

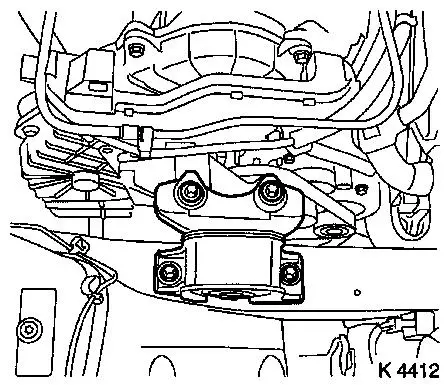

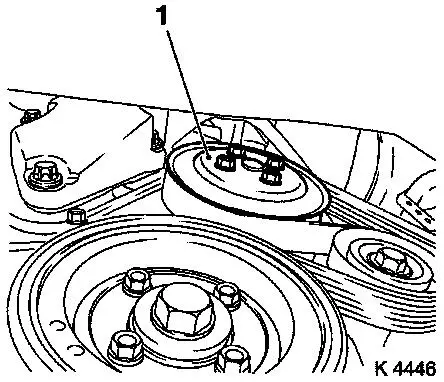

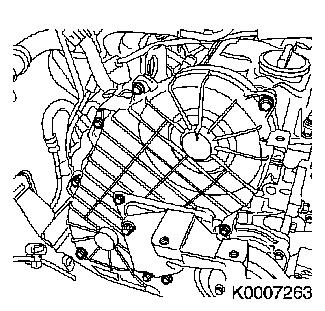

- Unscrew oil filter housing cover (1)

|

4. Remove oil dipstick guide tube

|

|

5. Loosen front right wheel

6. Raise vehicle

7. Remove front right wheel

8. Raise vehicle

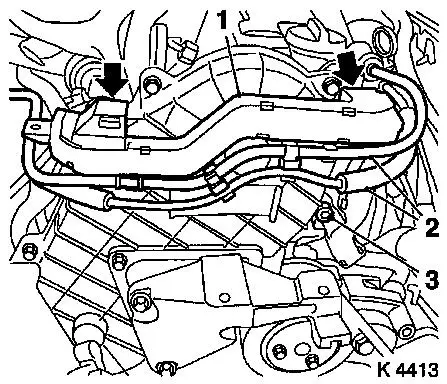

|

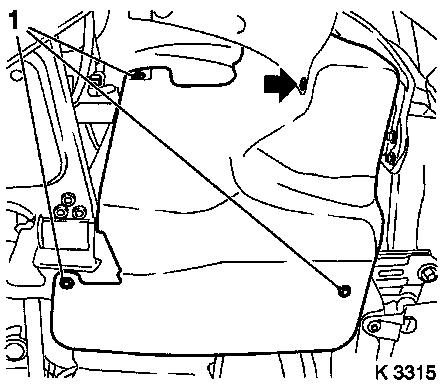

9. Remove ribbed V-belt cover

- Remove 3 bolts (1)

- Remove clip (arrow).

|

|

10. Drain engine oil

- Place collecting basin underneath.

- Remove drain bolt

11. Install drain bolt

- Replace seal ring

- Tighten bolt (78.4 Nm / 57.9 lbf. ft.)

|

12. Detach exhaust system

Note: When removing

the centre muffler, a catalytic converter, an exhaust manifold, or

an exhaust manifold with catalytic converter, secure that portion

of the exhaust system remaining on the vehicle against uncontrolled

suspension.

For this purpose, the exhaust system portion including the flexpipe

may be fastened to the vehicle underbody using suitable means, e.g.

wire.

Caution!

Angular dislocations of the flexpipe as

small as 5 to 10 degrees offset from the intended installation

position can already cause damage and subsequent complete failure

of the flexpipe.

- Detach rear muffler

- Release clamp

- Remove from rubber dampers

- Detach front exhaust pipe

|

|

13. Remove exhaust system

- Remove exhaust system

- Remove from 2 damping rings

- Note! 2. mechanic

14. Remove oil dipstick guide tube

|

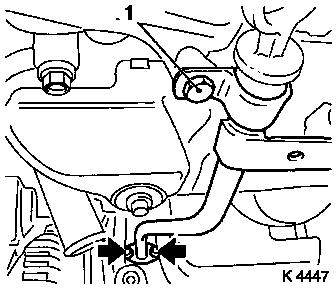

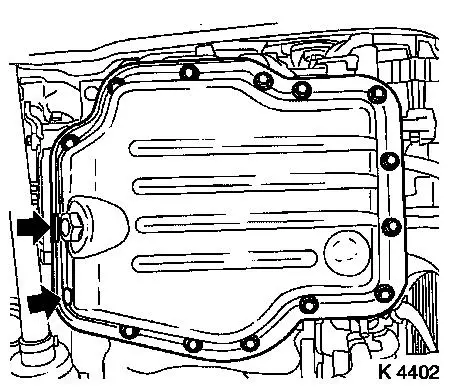

15. Detach lower part of oil pan

- Remove 15 bolts

- Detach with KM-J-37228

|

|

|

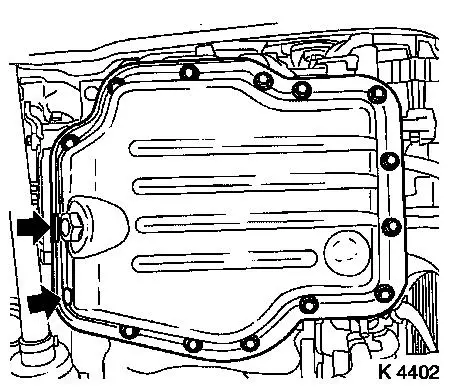

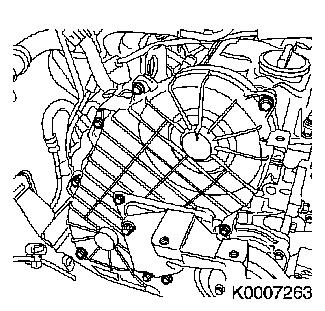

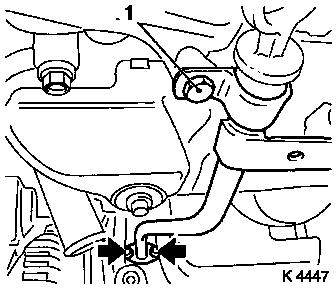

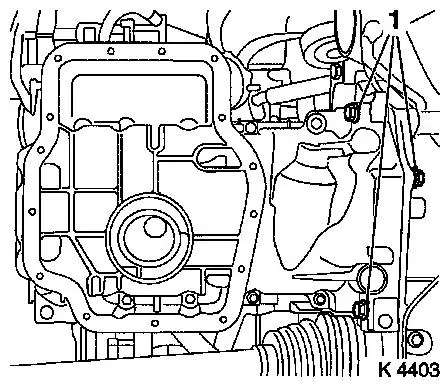

16. Detach upper part of oil pan

- Remove 14 bolts

- Note! Note dissimilar bolt lengths

- Remove 3 bolts (1)

- Remove 2 nuts

- Note! Use wide spatulas

|

|

17. Remove oil dipstick guide tube

|

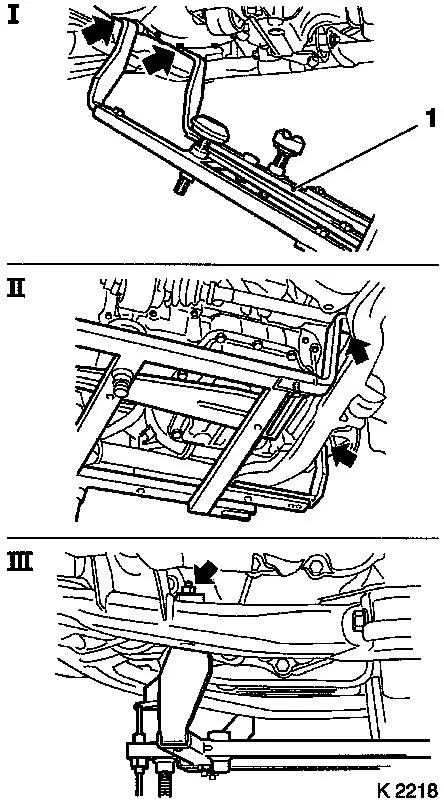

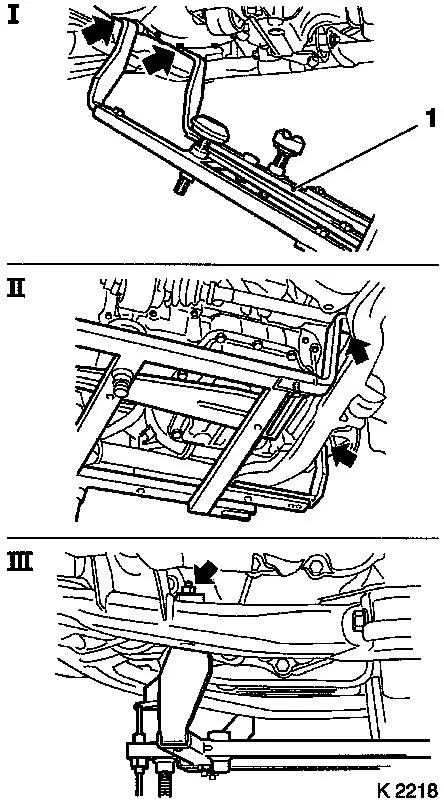

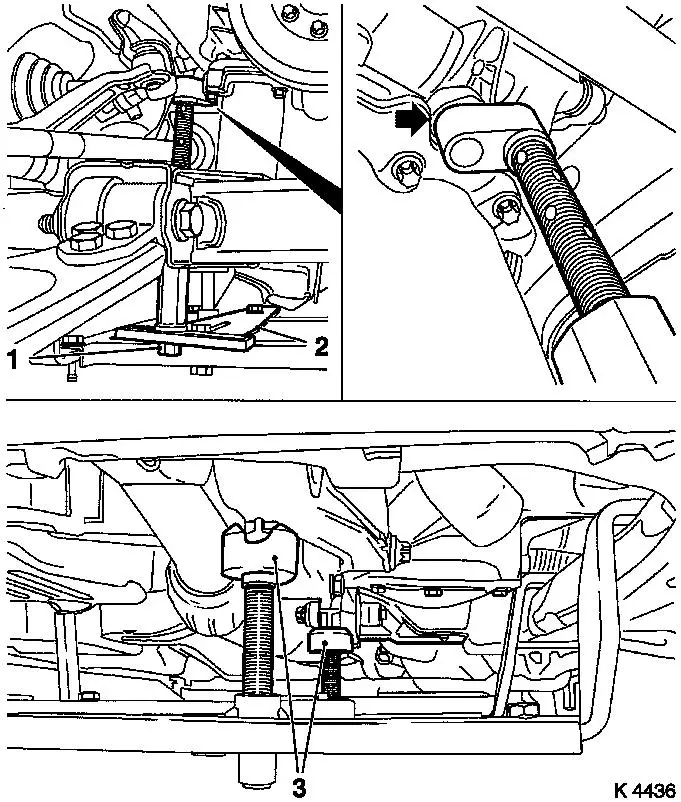

18. Attach KM-6169 (1)

- Place left of KM-6169 onto front axle body (arrows, illus.

I)

- Note! Guide pin must be seated in bore in front axle body

- Attach both right holders on the front axle body (arrows,

Illus. II).

- Note! Guide pin must be seated in bore in front axle body

(arrow, Illus. III)

- Tighten bolts

|

|

|

19. Install support

- To KM-6169

- Adjust bracket (2) for support

- Screw on nut (1)

|

|

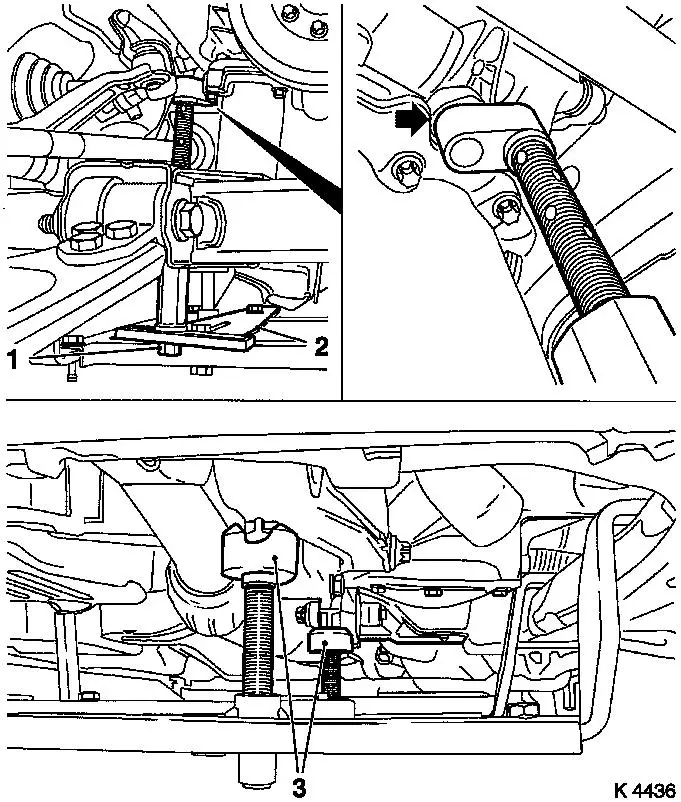

20. Adjust supports

- Transmission side

- Note! Turn spindles until the mounts (3) are positioned at the

guide journals free of play

- Engine timing side

- Insert journal of the support in the bore of the cylinder block

without play (arrow)

- Tighten nuts (1)

21. Lower vehicle

|

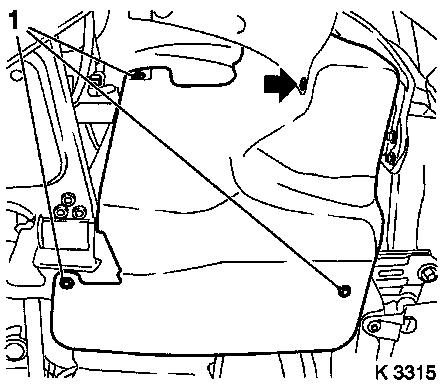

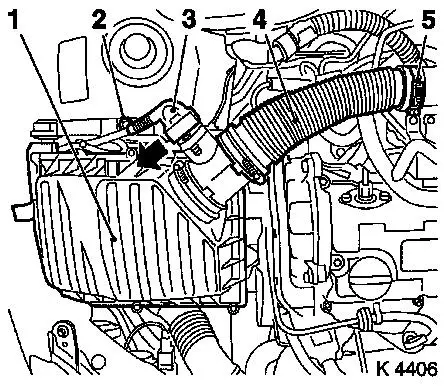

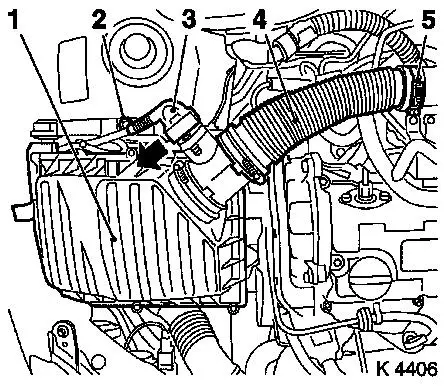

22. Remove air cleaner housing (1)

- Remove wiring harness plug for hot film mass air flow meter

(3)

- Release in direction of arrow

- Remove air intake hose (4)

- Remove bolt (2)

|

|

|

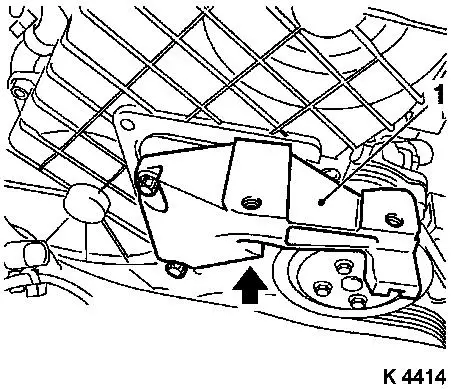

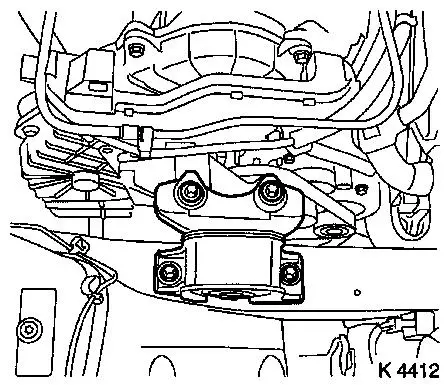

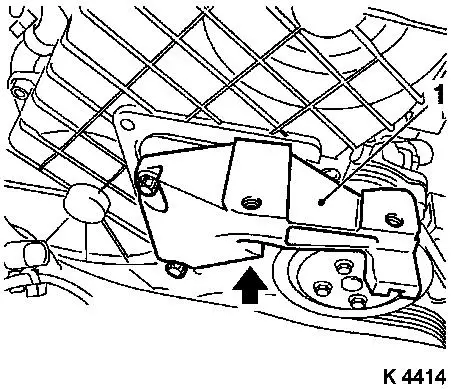

23. Remove right engine damping

block

|

|

24. Detach alternator wiring

harness

- Disconnect wiring harness plug

- Unscrew nut

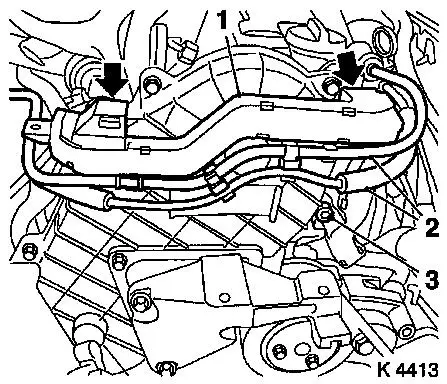

|

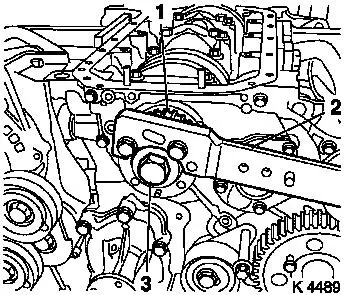

25. Remove wiring trough (1)

- Unclip vacuum lines (2)

- Unclip wiring trough

- Remove bolt (3)

|

|

|

26. Loosen upper part of toothed belt

cover

- Remove 8 bolts

- Note! Note dissimilar bolt lengths

|

|

|

27. Detach right engine bracket (1)

- Remove 3 bolts

- Remove right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

|

28. Raise vehicle

|

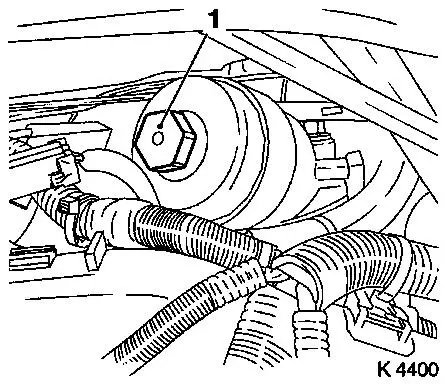

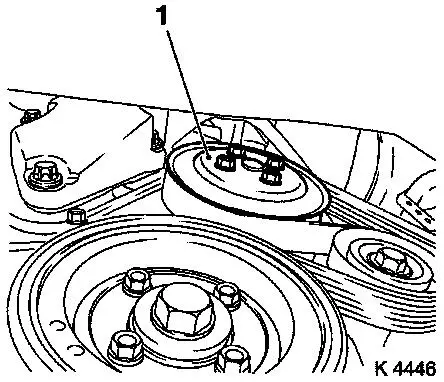

29. Loosen coolant pump ribbed V-belt

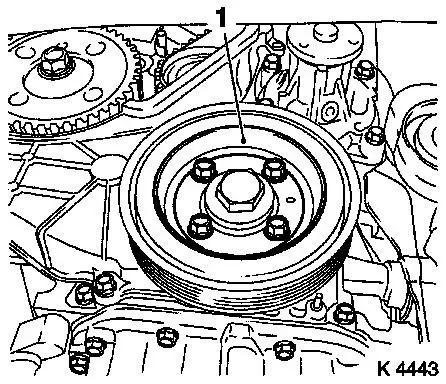

pulley (1)

|

|

|

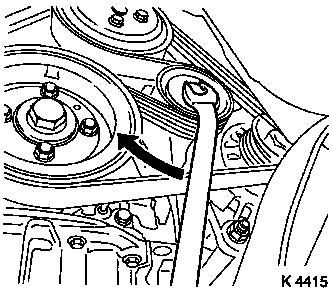

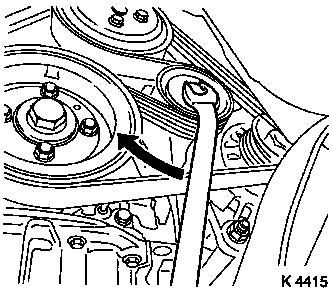

30. Remove ribbed V-belt

- Tension ribbed V-belt tensioner in direction of arrow

- Note! Mark running direction

|

|

31. Detach coolant pump ribbed V-belt

pulley

|

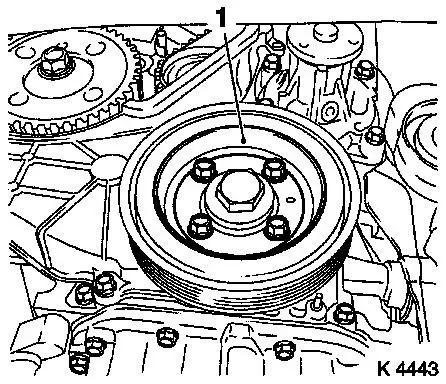

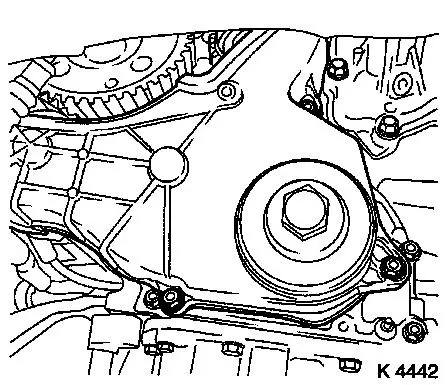

32. Remove torsional vibration damper

(1)

|

|

|

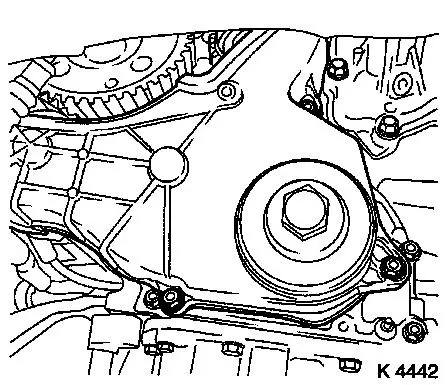

33. Detach lower part of toothed belt

cover

|

|

|

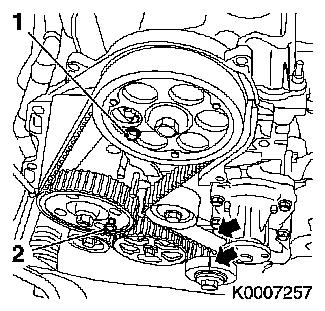

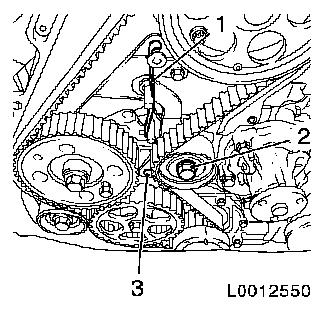

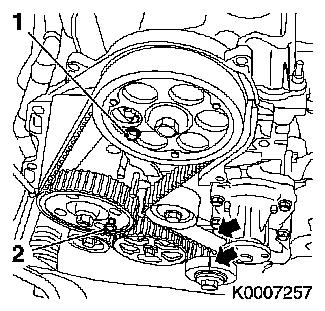

34. Set 1st cylinder to TDC

- Turn crankshaft evenly until TDC-fixing bolts can be

inserted

- Camshaft gear (M6) (1)

- Injection pump gear (M8) (2)

- Note! The mark on toothed belt drive gear must align with lug

on oil pump cover (arrows)

|

|

35. Lower vehicle

|

For toothed belt tension roller with

leaf spring:

- loosen toothed belt tensioner

- Screw in bolt (M10) in lower bore (3) of toothed belt

tensioner

- Loosen bolt (2)

- Remove tension spring (1)

|

|

|

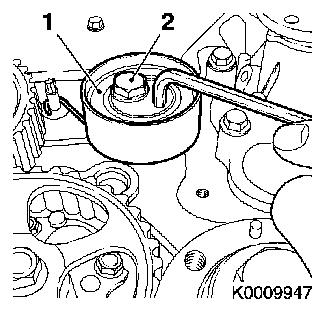

For toothed belt tension roller with

spiral spring:

- Loosen toothed belt tension roller (1)

- Rotate toothed belt tension roller anticlockwise approx.

90°

- Tighten bolt (2)

|

|

37. Remove toothed belt

- Note! Mark running direction

|

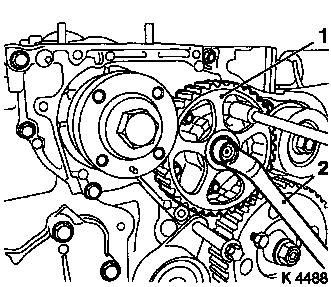

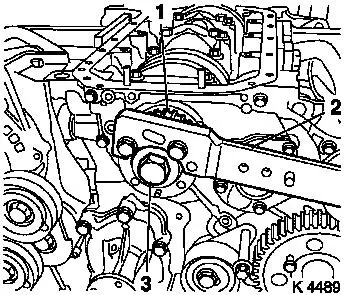

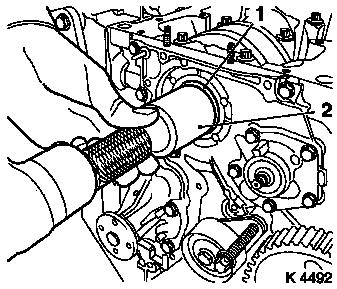

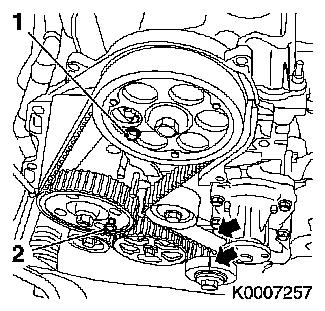

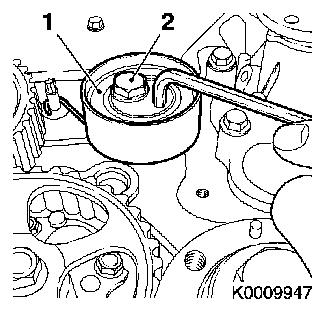

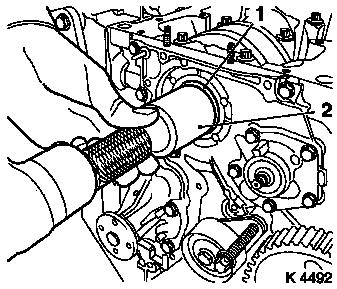

38. Remove oil pump drive gear (1)

- Unscrew nut

- Note! Counterhold using socket spanner (2)

|

|

39. Raise vehicle

|

40. Turn crankshaft

- Turn crankshaft to approx. 60° before TDC on power stroke

of 1st cylinder

|

|

41. Attach KM-662-C (2)

42. Detach toothed belt drive pulley

(1)

- Remove bolt (3)

- Counterhold using KM-662-C

- Remove toothed belt drive gear

- Remove woodruff key

|

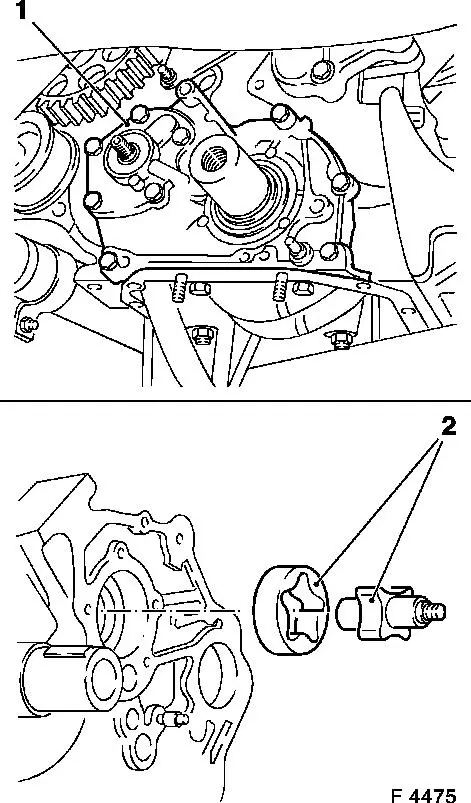

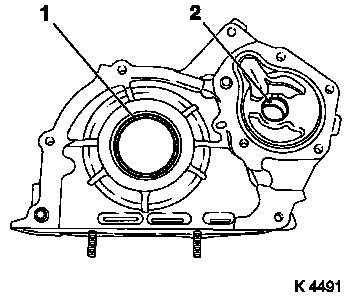

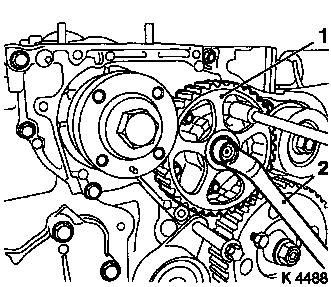

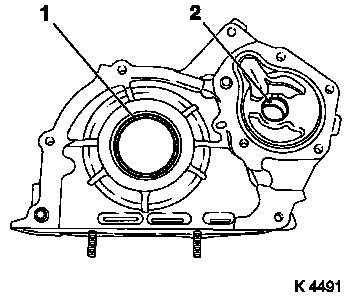

43. Remove oil pump cover (1)

- Remove 9 bolts

- Note! Note dissimilar bolt lengths

- Remove inner and outer rotors (2)

|

|

|

44. Clean sealing surfaces

- Cylinder block, oil pump cover

|

|

45. Inspect components

- Oil pump cover, cylinder block, inner rotor, outer rotor

46. Remove oil pump sealing ring

(2)

- Lever out seal ring

- Caution! Do not damage sealing surfaces

47. Remove crankshaft front seal ring

(1)

- Lever out seal ring

- Caution! Do not damage sealing surfaces

|

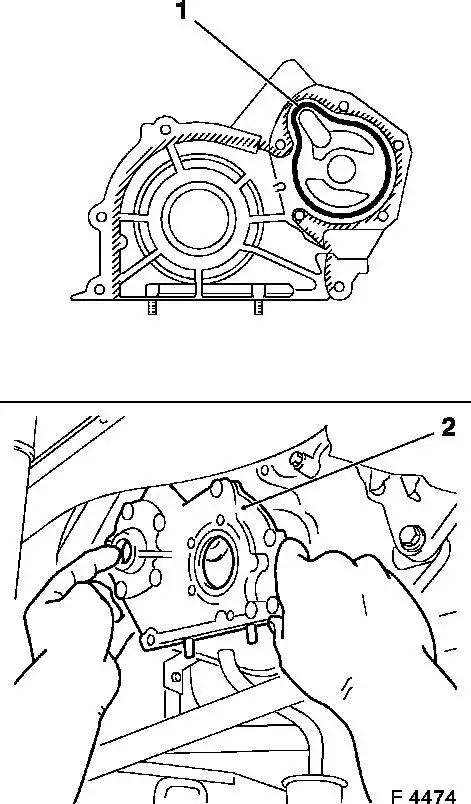

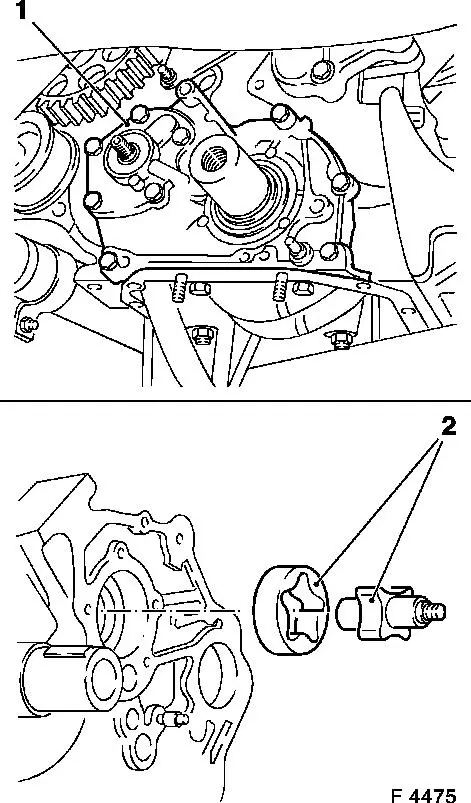

48. Install oil pump seal ring

- Lightly coat sealing lip of new seal ring with silicone grease

(white)

- Drive in until flush using KM-657

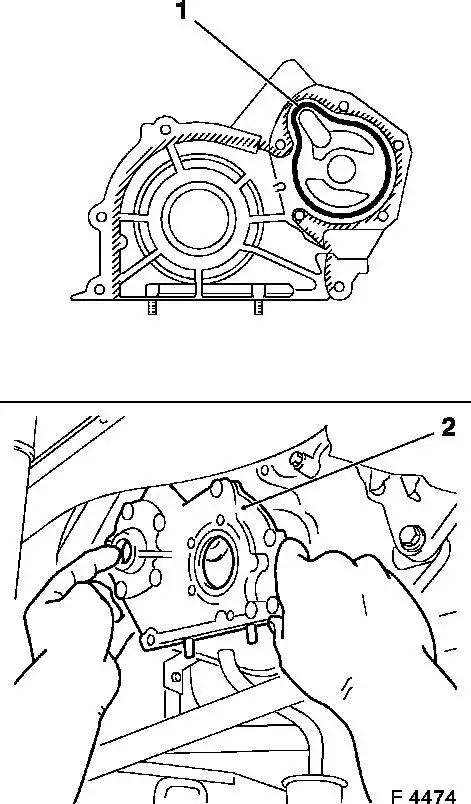

|

|

49. Install oil pump cover (2)

- Insert inner and outer rotor

- Clean thread.

- Replace gasket (1)

- Apply adhesive sealing compound (black) (shaded area)

- Attach oil pump cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

|

50. Install crankshaft front seal ring

(1)

- Lightly coat sealing lip of new seal ring with silicone grease

(white)

- Drive in until flush using KM-656 (2)

|

|

51. Install toothed belt drive gear

- Install sheet metal panel

- Insert toothed belt drive gear in place

- Tighten bolt (198 Nm / 146 lbf. ft.)

52. Remove KM-662-C

53. Lower vehicle

54. Install oil pump drive gear

- Note! Observe installation position

- Tighten nut (44.1 Nm/32.6 lbf. ft.)

55. Turn crankshaft

- Turn crankshaft to 1st Cylinder TDC

56. Install toothed belt

Note: Toothed belt

must be taut from toothed belt drive gear via oil pump drive gear

and injection pump drive gear

- For toothed belt tension roller with leaf spring:

- Unscrew TDC-fixing bolt

- Rotate crankshaft 60° against direction of engine

rotation

- Tighten bolt of toothed belt tension roller

- For toothed belt tension roller with spiral spring 49 Nm

- For toothed belt tension roller with leaf spring 38.2 Nm

57. For toothed belt tension roller with leaf spring: unscrew

bolt (M10) from lower bore of toothed belt tensioner

|

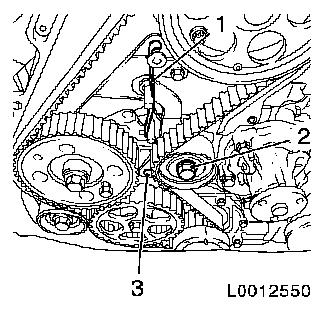

58. Set 1st cylinder to TDC of

combustion stroke

- Turn crankshaft approx. 780° in direction of engine

rotation

- Turn crankshaft evenly until TDC-fixing bolts can be

inserted

- Camshaft gear (M6) (1)

- Injection pump gear (M8) (2)

- Note! The mark on toothed belt drive gear must align with lug

on oil pump cover (arrows)

- Unscrew TDC-fixing bolts

|

|

59. Unscrew lower fastening bolt of toothed belt tension

roller

60. Attach lower part of toothed belt

cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

61. Attach right engine bracket

- Insert lower bolt

- Into right engine bracket and right engine bracket adapter

- Insert right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

- Install 2 upper bolts

- Tighten 3 bolts (40 Nm / 29.5 lbf. ft.)

62. Install right engine damping

block

- To side member

- Tighten bolts (40 Nm / 29.5 lbf. ft.)

- On engine bracket

- Tighten bolts (60 Nm/44 lbf. ft + 30° + 15°.)

63. Fasten upper part of toothed belt

cover

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

- Note! Note dissimilar bolt lengths

64. Attach coolant pump ribbed V-belt

pulley

65. Raise vehicle

66. Install torsional vibration

damper

- Tighten bolts (19.6 Nm / 14.5 lbf. ft.)

67. Install ribbed V-belt

- Note! Observe running direction and installation position

- Release ribbed V-belt tensioner

68. Fasten coolant pump ribbed V-belt

pulley

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

69. Detach support

70. Remove KM-6169

71. Clean sealing surfaces

- Cylinder block, upper part of oil pan, lower part of oil

pan

72. Install upper part of oil pan

- Apply sealing compound (grey)

- Caution! The application of silicone sealing compound (grey)

and installation of lower part of oil pan including torque test

must be performed within 10 minutes!

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

- Tighten nuts (9.8 Nm / 7.2 lbf. ft.)

- Bolts (M10) (40 Nm / 29.5 lbf. ft.)

73. Attach lower part of oil pan

- Apply sealing compound (grey)

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

74. Insert front exhaust pipe

- Into isolator rings

- Note! 2. mechanic

75. Fasten front exhaust pipe

- Replace gasket

- Tighten 2 nuts (65 Nm / 47.9 lbf. ft.)

76. Insert rear muffler

77. Fasten rear muffler

78. Attach ribbed V-belt cover

- Install 3 bolts

- Install clip

79. Lower vehicle

80. Install right front wheel

81. Lower vehicle

82. Fasten right front wheel

- Tighten bolts (110 Nm / 81 lbf. ft.)

83. Insert oil dipstick guide tube

84. Raise vehicle

85. Install oil dipstick guide tube

- Tighten bolts (9.8 Nm / 7.2 lbf. ft.)

86. Lower vehicle

87. Install oil dipstick guide tube

88. Attach wiring trough

- Clip-in wiring trough

- Clip in vacuum lines

- Tighten bolt

89. Attach alternator wiring

harness

- Connect wiring harness plug.

- Tighten nuts

90. Install air cleaner housing

- Tighten bolt

- Fasten air intake hose.

- Connect wiring harness plug to hot film mass air flow

meter

91. Connect battery

92. Calibrate steering angle sensor

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

93. Top up engine oil

- Observe specified engine oil quantity

- Start engine and allow to run until oil pressure telltale

extinguishes.

- Check engine oil level, if necessary correct.

94. Program volatile memories

95. Close bonnet

|