|

Replace front crankshaft sealing ring (Y 17 DTL,

with air conditioning, LHD)

Note: KM-6394 must be used from model year 04 instead of

KM-6169-1 .

Important: On vehicles from model

year 04 with ESP - the steering angle sensor loses its basic

adjustment each time the battery is disconnected. It must be

recalibrated.

|

| 2. |

Disconnect battery

|

| 3. |

Detach front right wheel

|

| 5. |

Remove front right wheel

|

| 7. |

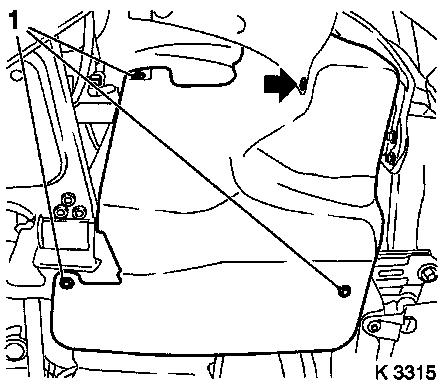

Remove ribbed V-belt cover

|

|

|

| 8. |

Detach alternator wiring harness

| • |

Disconnect wiring harness plug

|

|

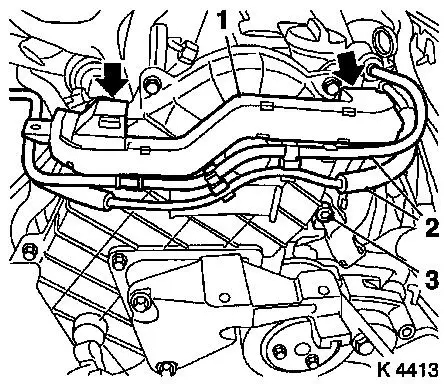

| 9. |

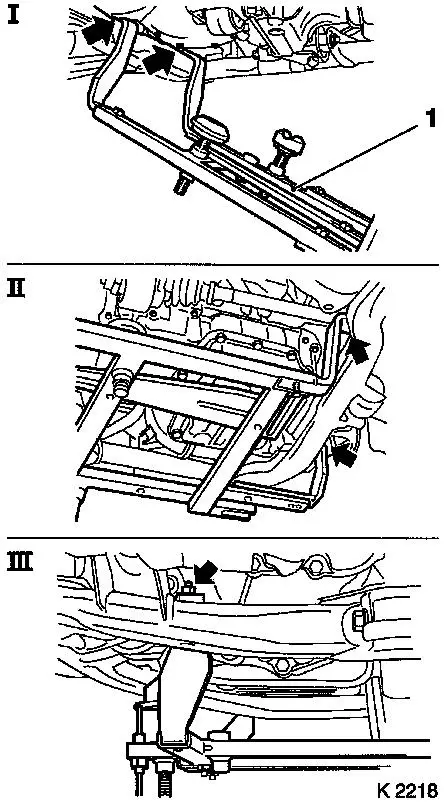

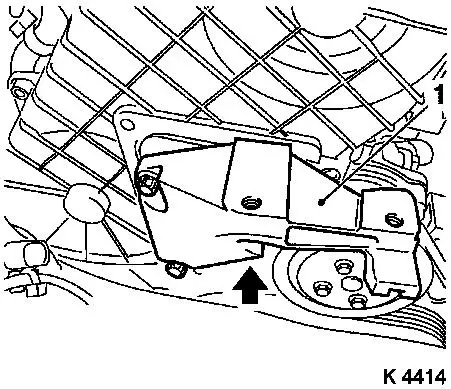

Attach KM-6169 (1)

| • |

Attach KM-6169 at left side of front

axle unit (arrows, fig.I)

Note: Guide pin must be

seated in bore in front axle body

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

Note: Guide pin must be

seated in bore in front axle body

|

| • |

Tighten bolts (arrows, fig. III)

|

|

|

|

| 10. |

Install support

| • |

An KM-6169

| – |

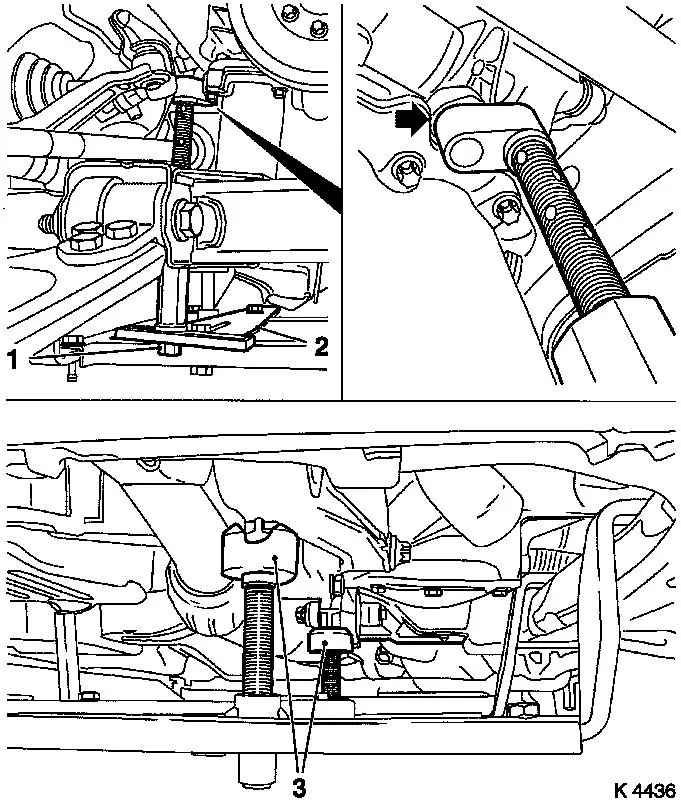

Adjust bracket (2) for support

|

|

|

| 11. |

Adjust supports

| • |

Transmission side

Note: Turn spindles (3)

until mounts are positioned at guide journals free of play

|

| • |

Engine timing side

| – |

Insert support pin in cylinder block bore without play

(arrows)

|

|

|

|

|

| 12. |

Loosen coolant pump ribbed V-belt pulley

|

| 13. |

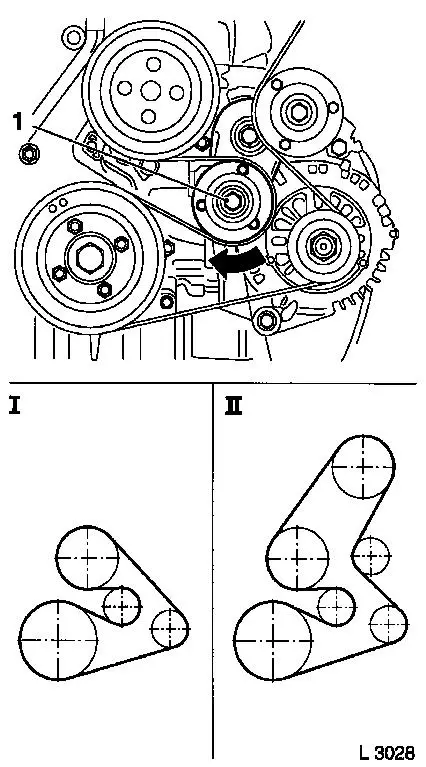

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow

Note: Mark direction of

rotation

|

|

|

|

| 14. |

Detach coolant pump ribbed V-belt pulley

|

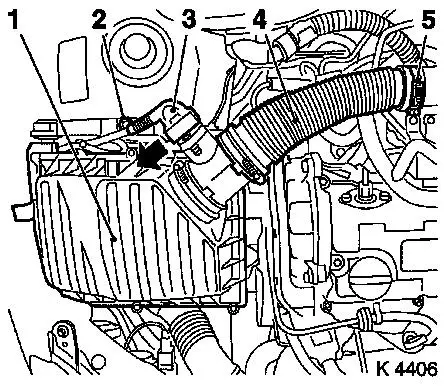

| 16. |

Remove air cleaner housing (1)

| • |

Remove wiring harness plug for hot film mass air flow meter

(3)

| – |

Release in direction of arrow

|

|

| • |

Remove air intake hose (4)

|

|

|

|

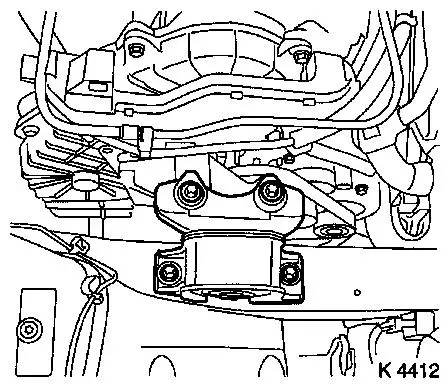

| 17. |

Remove right engine damping block

|

|

|

| 18. |

Remove wiring trough (1)

| • |

Unclip vacuum lines (2)

|

|

|

|

| 19. |

Loosen upper part of toothed belt cover

| • |

Remove 8 bolts

Note: Note dissimilar

bolt lengths

|

|

|

|

| 20. |

Detach right engine bracket (1)

| • |

Remove right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

|

|

|

| 22. |

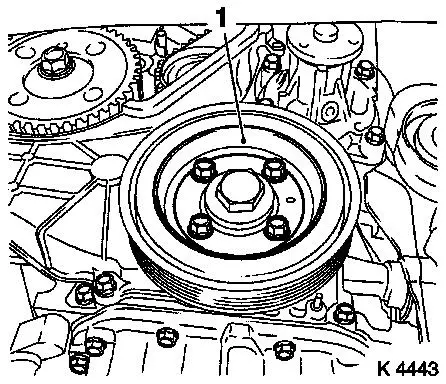

Remove torsional vibration damper (1)

|

|

|

| 23. |

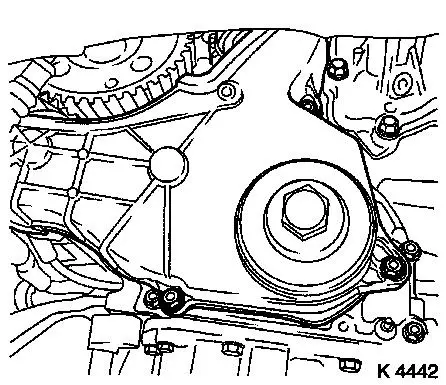

Detach lower part of toothed belt cover

|

|

|

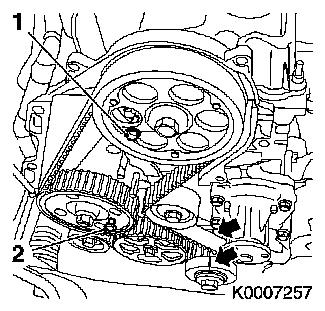

| 24. |

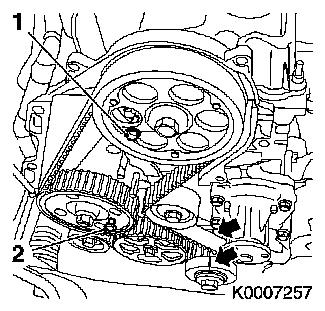

Set no.1 cylinder to TDC

| • |

Turn crankshaft evenly until TDC-fixing bolts can be

inserted

| – |

Injection pump drive gear M8 (2)

Note: Mark on toothed

belt drive gear must align with lug on oil pump cover (arrows)

|

|

|

|

|

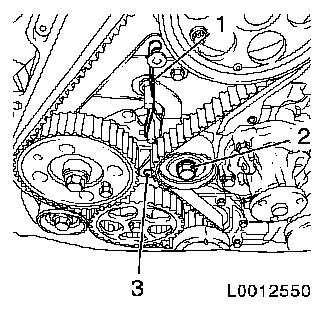

| 26. |

For toothed belt tension roller with leaf spring:

| • |

loosen toothed belt tensioner

| – |

Screw in bolt (M10) in lower bore (3) of toothed belt

tensioner

|

| – |

Remove tension spring (1)

|

|

|

|

|

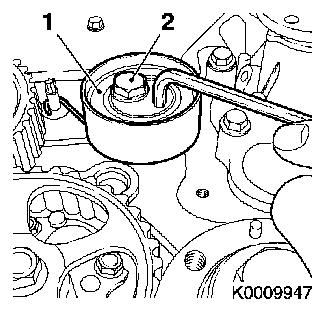

| 27. |

For toothed belt tension roller with spiral spring:

| • |

Loosen toothed belt tension roller (1)

| – |

Rotate toothed belt tension roller anticlockwise approx.

90°

|

|

|

|

|

| 28. |

Remove toothed belt

Note: Mark direction of

rotation

|

| 30. |

Remove oil pump drive gear (1)

| • |

Unscrew nut

Note: Counterhold using

socket wrench and unscrew nut using spanner (2).

|

|

|

|

| 31. |

Turn crankshaft

| • |

Turn crankshaft to approx. 60° before no.1 cylinder TDC

|

|

| 33. |

Remove toothed belt drive gear

| • |

Remove bolt

| – |

Counterhold using KM-662-C

|

|

| • |

Remove toothed belt drive gear (1)

|

|

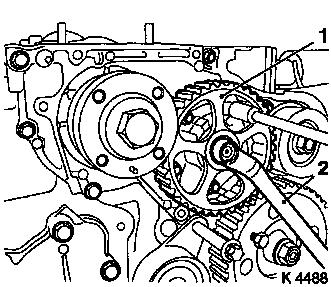

| 34. |

Remove front crankshaft sealing ring

Important: Do not damage sealing

surfaces

|

| • |

Prise out sealing ring (3)

|

|

|

|

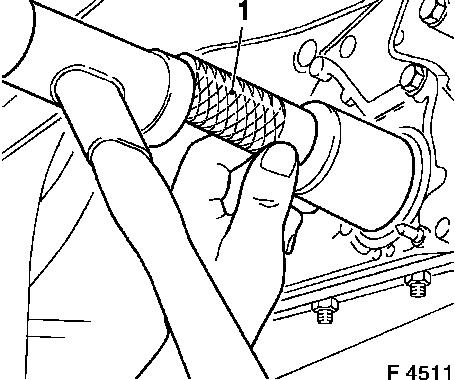

| 35. |

Install front crankshaft sealing ring

| • |

Coat lip of new sealing ring with silicon grease (white)

|

| • |

Drive in until flush using KM-656

(1)

|

|

|

|

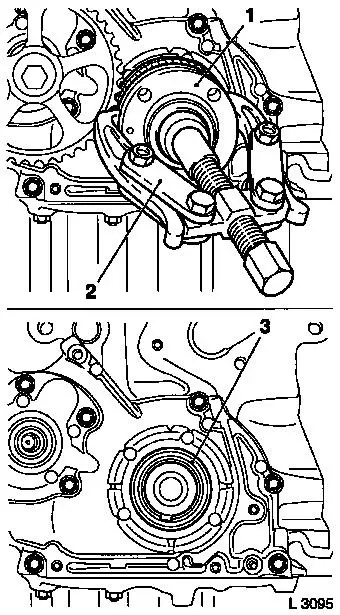

| 36. |

Install toothed belt drive gear

| • |

Install sheet metal panel

|

| • |

Put toothed belt drive gear on

| – |

Pay attention to spring washer

|

|

| • |

Tighten bolt ( 196 Nm )

|

|

| 38. |

Install oil pump drive gear

Note: Pay attention to

installation position

| • |

Tighten nut ( 44.1 Nm )

|

|

| 40. |

Turn crankshaft

| • |

Turn crankshaft to 1st Cylinder TDC

|

|

| 41. |

Install toothed belt

| • |

Position toothed belt

Note: Toothed belt must

be taut from toothed belt drive gear via oil pump drive gear and

injection pump drive gear

|

| • |

For toothed belt tension roller with leaf spring:

|

| • |

Unscrew TDC-fixing bolt

|

| • |

Rotate crankshaft 60° against direction of engine

rotation

|

| • |

Tighten bolt of toothed belt tension roller

| – |

For toothed belt tension roller with spiral spring 49 Nm

|

| – |

For toothed belt tension roller with leaf spring 38.2 Nm

|

|

| • |

For toothed belt tension roller with leaf spring: unscrew bolt

(M10) from lower bore of toothed belt tensioner

|

|

| 42. |

Timing, Check

| • |

Turn crankshaft approx. 780° in direction of engine

rotation

|

| • |

The mark on toothed belt drive gear must align with lug on oil

pump cover (arrows)

|

| • |

Install TDC-fixing bolts (1, 2)

Note: If the TDC fixing

bolts cannot be screwed in, basic adjustment must be repeated

|

| • |

Unscrew TDC-fixing bolts

|

|

|

|

| 43. |

Unscrew lower fastening bolt of toothed belt tension roller

|

| 44. |

Attach lower part of toothed belt cover

| • |

Tighten bolts ( 9.8 Nm )

|

|

| 45. |

Attach right engine bracket

| • |

Insert lower bolt

| – |

Into right engine bracket and right engine bracket adapter

|

|

| • |

Insert right engine bracket, right engine bracket adapter,

upper part of toothed belt cover

|

| • |

Tighten 3 bolts( 40 Nm )

|

|

| 46. |

Fasten upper part of toothed belt cover

| • |

Tighten bolts ( 9.8 Nm )

Note: Note dissimilar

bolt lengths

|

|

| 48. |

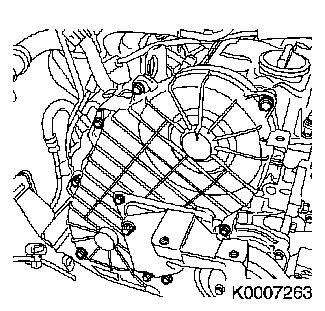

Install right engine damping block

| • |

To side member

| – |

Tighten bolts ( 40 Nm )

|

|

| • |

On engine bracket

| – |

Tighten bolts ( 60 Nm + 30° +

15° )

|

|

|

| 50. |

Attach coolant pump ribbed V-belt pulley

|

| 51. |

Install torsional vibration damper

| • |

Tighten bolts ( 19.6 Nm )

|

|

| 52. |

Install ribbed V-belt

Note: Pay attention to

running direction and installation position

| • |

Release ribbed V-belt tensioner

|

|

| 53. |

Fasten coolant pump ribbed V-belt pulley

| • |

Tighten bolts ( 9.8 Nm )

|

|

| 56. |

Attach alternator wiring harness

| • |

Connect wiring harness plug.

|

|

| 57. |

Attach ribbed V-belt cover

|

| 59. |

Install right front wheel

|

| 61. |

Fasten right front wheel

| • |

Tighten bolts ( 110 Nm )

|

|

| 62. |

Install air cleaner housing

| • |

Fasten air intake hose.

|

| • |

Connect wiring harness plug to hot film mass air flow meter

|

|

| 63. |

Check and correct engine oil level

| • |

Observe specified engine oil quantity

|

|

| 65. |

Calibrate steering angle sensor

| • |

Switch on ignition

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

|

|

| 66. |

Program volatile memories

|

|