|

Checking engine pressure loss

Remove Remove

| 3. |

Remove air intake hose

|

|

| 4. |

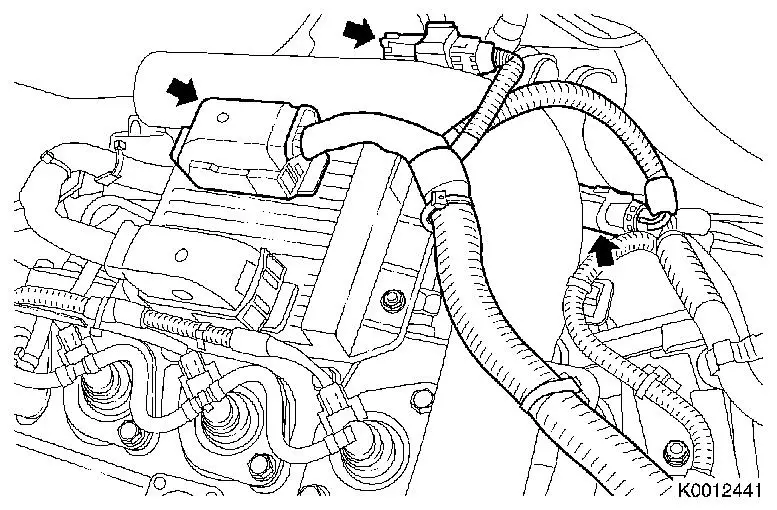

Remove engine management wiring harness

| • |

Disconnect 3 wiring harness plugs (arrows)

|

|

|

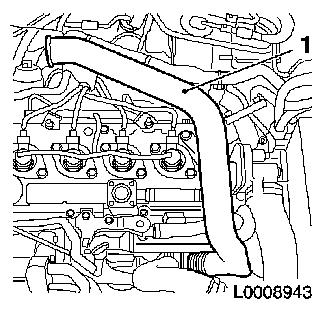

| 5. |

Loosen air intake pipe (1)

| • |

Remove engine vent hose

|

|

|

|

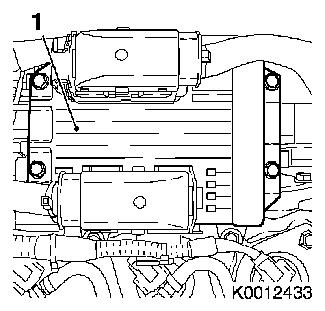

| 6. |

Remove engine control unit (1)

| • |

Release wiring harness plug in direction of arrow

|

|

|

|

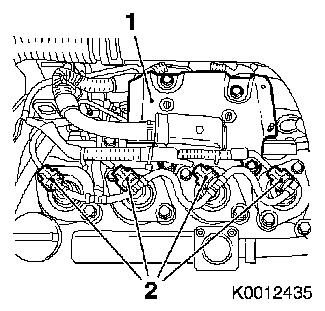

| 7. |

Disconnect 4 wiring harness plugs, injector (2)

|

| 8. |

Detach engine control unit bracket (1)

|

|

|

| 9. |

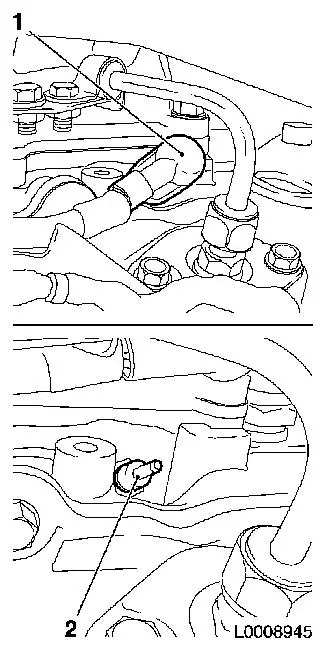

Disconnect 4x wiring harness plug, sheathed glow plug (1)

|

| 10. |

Remove 4x sheathed glow plug (2)

|

|

|

| 11. |

Raise vehicle all the way

|

| 12. |

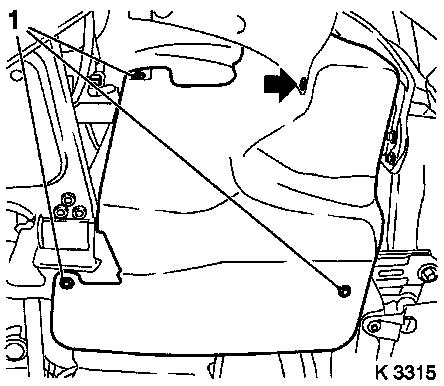

Remove right engine splash guard

| • |

Remove body-bound rivet (arrow)

|

|

|

|

| 13. |

Remove coolant compensation tank cap, oil filler port closure

cap and oil dipstick

|

Inspect

Inspect

| 14. |

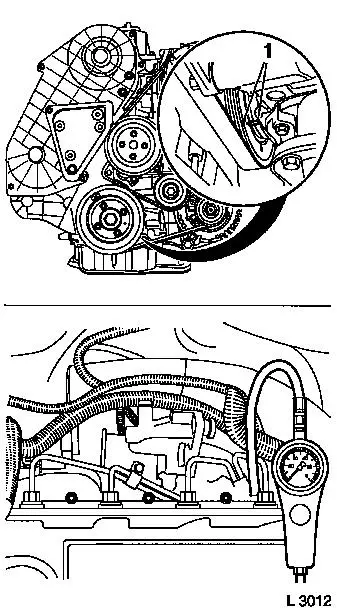

Set crankshaft to "1st cylinder TDC" following direction of

engine rotation

| • |

The markings (1) must align

Note: The cams of 1st

cylinder must face up - Cam position can be checked via the oil

filler port. If 1st cylinder cams do not face up, turn the

crankshaft one revolution to "1st cylinder TDC".

|

|

| 15. |

Affix guide marking to torsional vibration damper

Note: Guide marking

must be exactly 180° across from TDC marking

|

| 16. |

Attach pressure loss tester

| • |

Together with connector KM-6367

|

| • |

Calibrate pressure loss tester

Note: Follow

manufacturer's instructions

|

|

|

|

| 17. |

Engage 4th gear; apply handbrake

|

| 18. |

Check 1st cylinder pressure loss

| • |

Max. pressure difference between individual cylinders - approx.

10 %

|

| • |

Pressure loss per cylinder should not exceed 25 %

|

| • |

Check the following for air discharge to locate any damage:

| – |

Coolant compensation tank, dipstick guide tube

|

|

|

| 19. |

Detach pressure loss tester

| • |

Together with connector KM-6107

|

|

| 20. |

Repeat pressure loss test for 3rd, 4th and 2nd cylinder

Note: Turn crankshaft

180° to guide marking or TDC marking

|

Install

Install

| 21. |

Fit coolant compensation tank cap, oil filler port closure cap

and oil dipstick

|

| 22. |

Install 4 sheathed glow plugs 17.5

Nm

|

| 23. |

Connect 4x injector wiring harness plug

|

| 24. |

Attach engine control unit bracket

|

| 25. |

Connect 4x injector wiring harness plug

|

| 26. |

Fit engine control unit

| • |

Connect wiring harness plug

|

|

| 27. |

Fasten air intake pipe

|

| 28. |

Attach engine management wiring harness

| • |

Connect 3 wiring harness plugs

|

|

| 29. |

Install air intake hose.

|

| 32. |

Calibrate steering angle sensor

| • |

Turn on ignition

Note: Rotate the

steering wheel one time from its right-hand to its left-hand

stop.

|

|

| 33. |

Program volatile memory

|

|