|

Valve seat, cut (in cylinder head)

Special service tools required:

Valve seat cutter set KM-340-G, KM-340-100

Note: For use of

valve cutter set KM-340-G / 340-100, consult the accompanying

instructions.

The guide drift is identical for the intake and exhaust

sides.

|

Valve stem Ø

|

Guide drift

|

|

5 mm

|

KM-340-30, KM-340-100-3

|

|

6 mm

|

KM-340-27, KM-340-100-4

|

|

7 mm

|

KM-340-7

|

|

8 mm

|

KM-340-23

|

|

Angle

|

Cutter

|

| |

for petrol engines

|

|

15°

|

KM-340-26, -28

|

|

30°

|

KM-340-11, -12, -13, -29, KM-340-100-1

|

|

45°

|

KM-340-11, -12, -13, -29, KM-340-100-2

|

|

60 °

|

KM-340-26, -28

|

| |

for diesel engines

|

|

15°

|

KM-340-25

|

|

45°

|

KM-340-25, KM-340-100-2

|

|

75°

|

KM-340-14

|

Caution

The 15° and 75° cutters must only be used for certain

diesel engines.

|

Install

Install

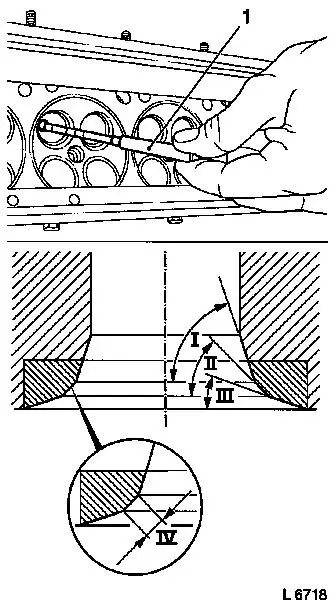

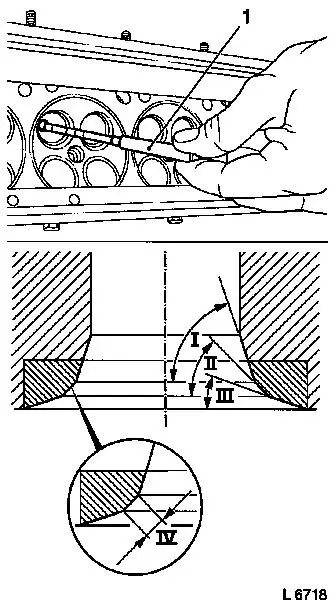

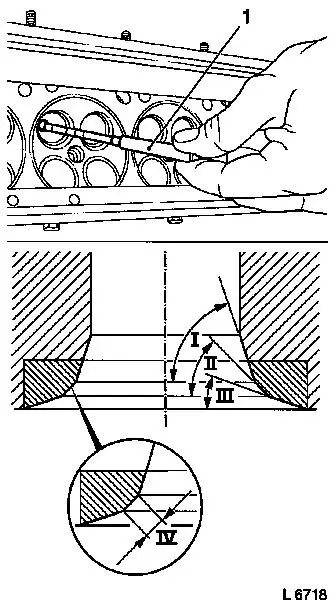

Insert guide drift (1) from valve cutter set in the valve guide

and tension. Ensure that the guide drift is inserted to 2 – 3

mm from the stop only. Ensure that the valve guides are OK. These

are used to hold the guide drift.

Procedure

|

Sequence of operations:

|

|

I

|

Lower correction angle

|

|

II

|

Valve seat angle

|

|

III

|

Upper correction angle

|

|

IV

|

Valve seat width

|

|

|

|

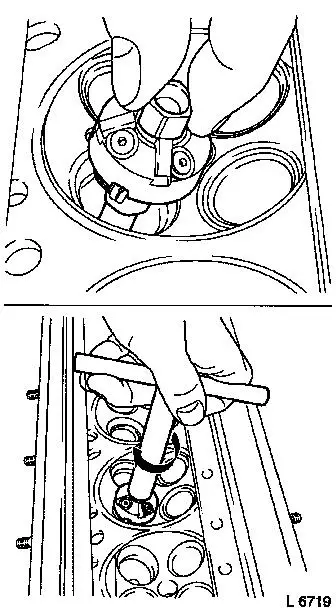

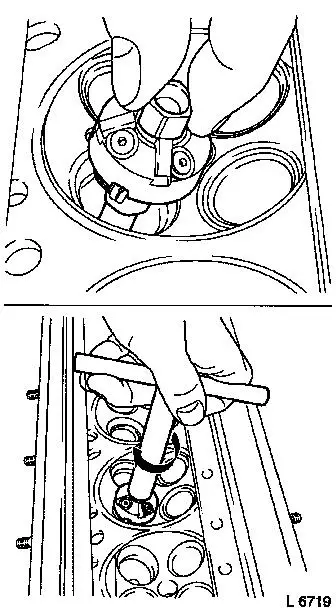

Slide the cutter over the guide drift at the specified angle.

Install turning knob.

Note: If necessary

release the cutting stones of the valve seat cutter and adjust them

to the diameter of the valve seat by sliding them.

Procedure

Cut valve seats and correction angle clockwise exerting light

pressure.

|

|

|

Release guide drift (1) and remove from

valve guide. The valve seat contact pattern is checked using a new

valve and blue ink.

- Lower correction angle

- Valve seat angle

- Upper correction angle

- Valve seat width

The valve width dimensions can be found in the "Technical

Data".

After cutting the valve seat, the valve indentation/installation

height of valves must be checked.

Clean Clean

Clean cylinder head after completing operations.

The valves must be ground and ground-in before installation.

|

|

|