|

J340100-008 remove and install automatic

transmission with engine torque converter (Z14 XE, AC, RHD)

|

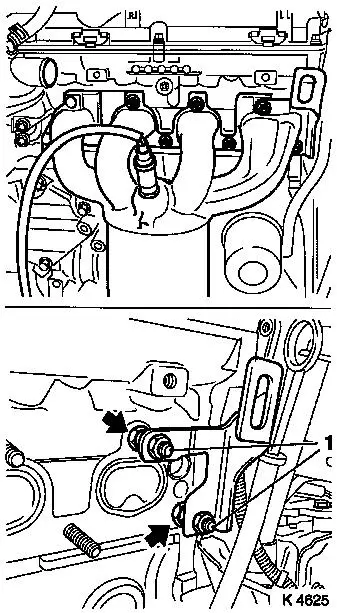

1. Remove exhaust manifold heat shield

- Disconnect mixture regulating oxygen sensor wiring harness

plug

- Remove 3 bolts

2. Remove exhaust manifold

- Remove 9 nuts

- Remove gasket.

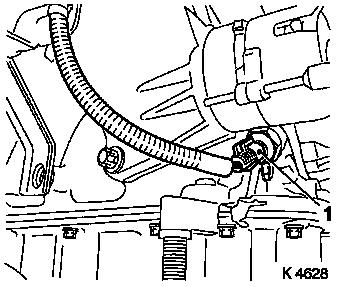

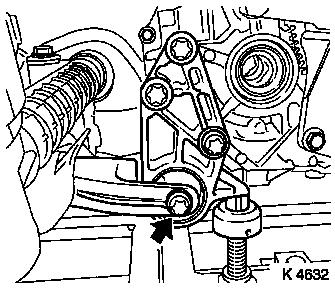

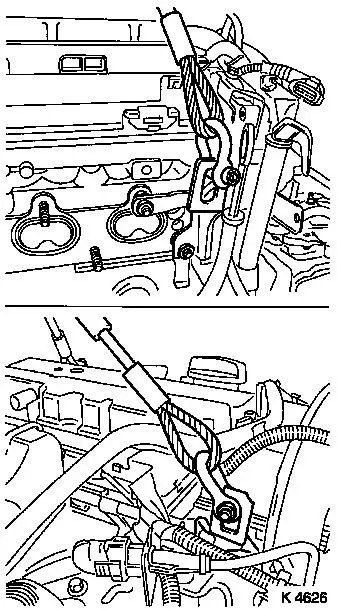

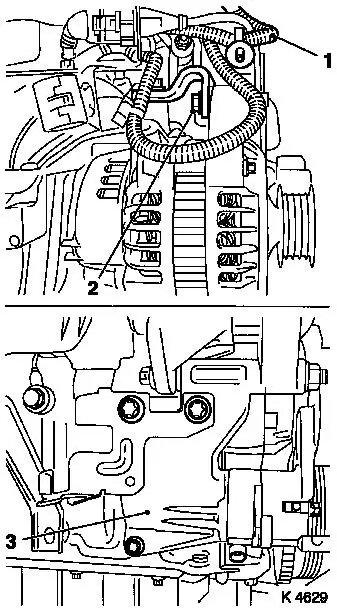

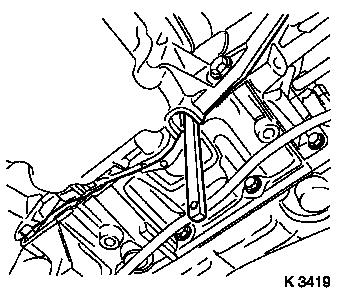

3. Attach engine transport shackle

- Insert 4 nuts (M 10) (arrows)

- Tighten 2 nuts (M8) (22 Nm / 16 lbf. ft.) (1)

|

|

|

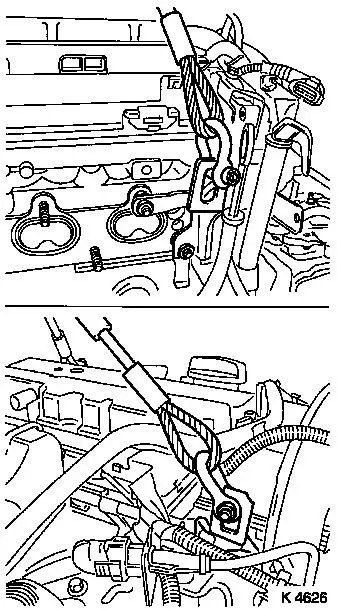

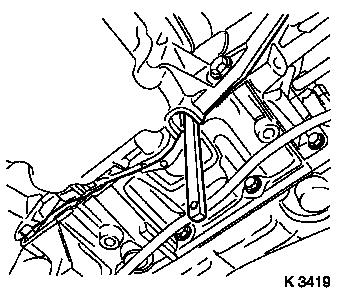

4. Attach cables to drive unit

- Attach KM-2358

- 2 off

- Attach workshop crane

|

|

|

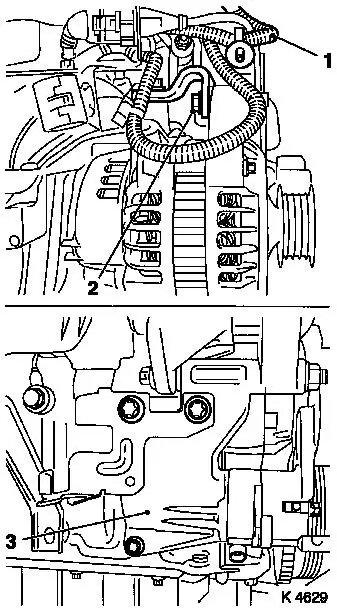

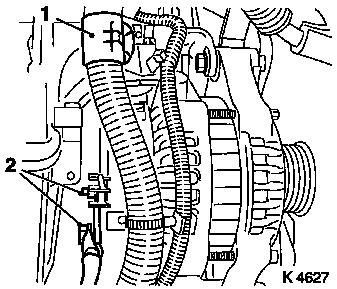

5. Detach engine wiring harness

|

|

- From starter

- From alternator

- Detach ground cable

- Unclip wiring harness (1)

|

|

|

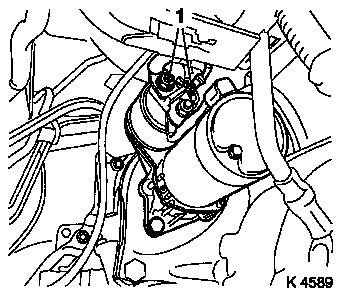

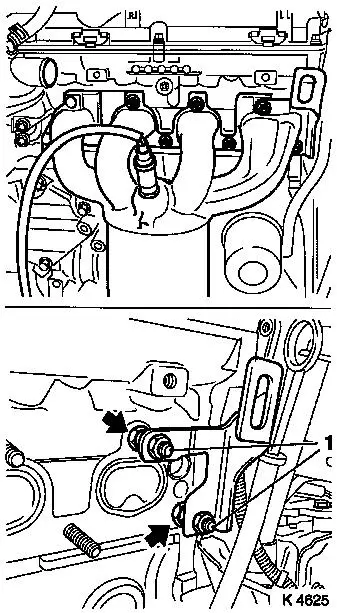

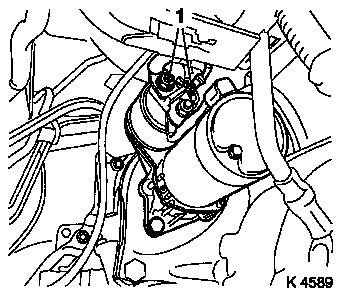

6. Disconnect oil pressure switch

wiring harness plug (1)

|

|

|

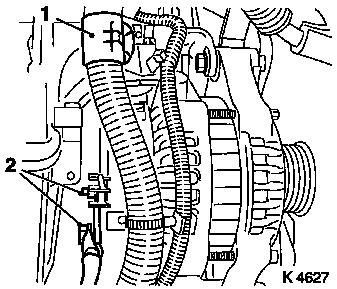

7. Detach alternator

- Loosen alternator support

- Unclip wiring harness (1)

- Remove bolt (2)

- Detach alternator support (3)

|

|

|

8. Detach intake manifold support

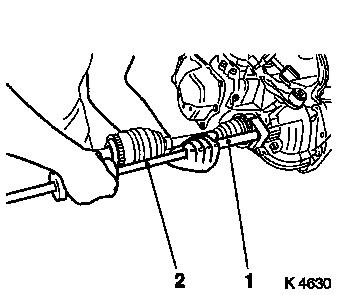

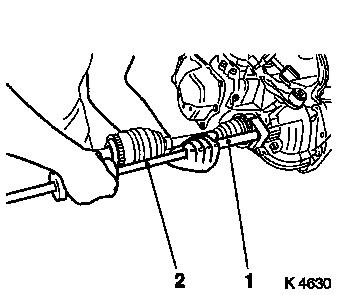

9. Unscrew axle shafts

- Note: 2nd person required

- Place collecting basin underneath.

- Using KM-313 (2), KM-902 (1)

- Seal openings

|

|

|

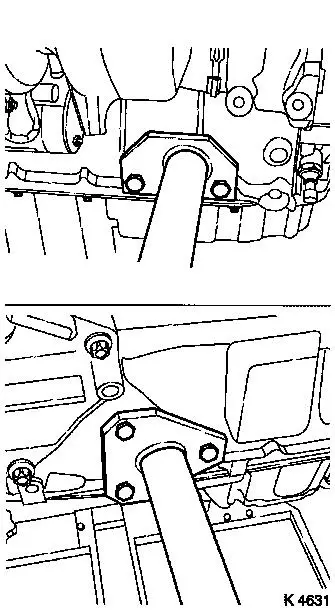

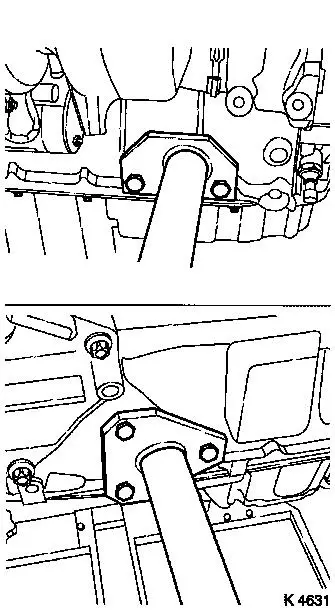

10. Attach KM-412-3

|

|

|

11. Loosen rear reaction member

12. Lift up drive unit

- Caution: Do not damage attaching parts

- Note: 2nd person required

13. Install drive unit

- Note: 2nd person required

- To KM-412

14. Lower drive unit on cables

|

|

|

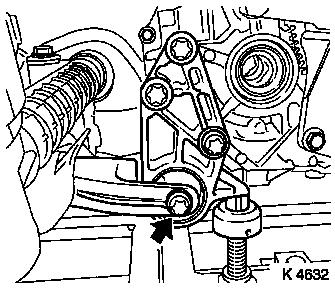

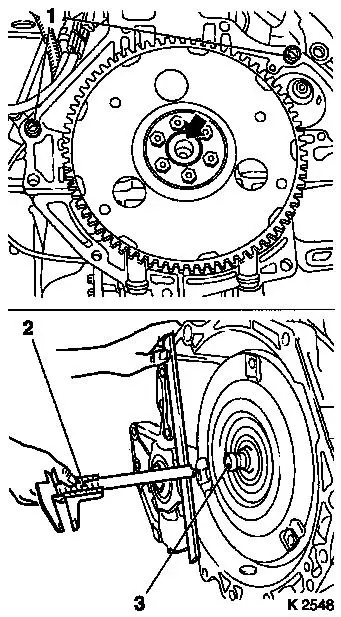

15. Loosen torque converter

- Remove 2 closure plugs

- Turn crankshaft in direction of engine rotation using

crankshaft ribbed V-belt pulley bolt

- Use KM-911

- Remove 3 bolts

16. Attach KM-910

17. Loosen automatic transmission

18. Lift automatic transmission

- Note: 2nd person required

- Lower engine

- Remove bolt

- Caution: Note torque converter

|

|

|

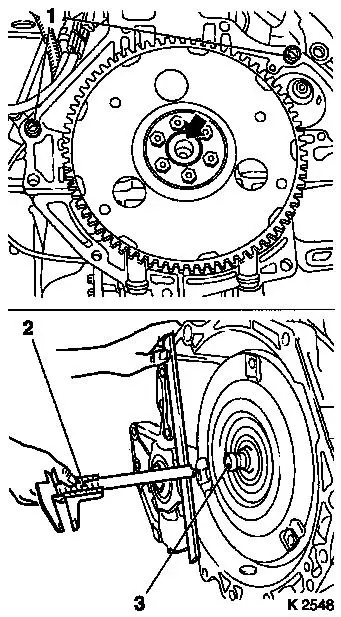

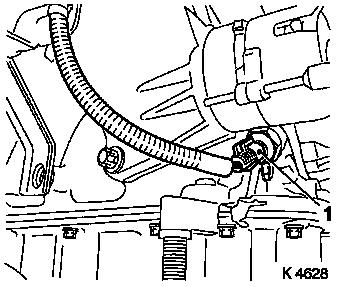

19. Check centring journal

- Check converter centring journal for rust and clean if

necessary

- Measure distance between connecting threads of converter and

the mating surface of the transmission housing with calliper gauge

(2): Gap approx. 12 mm

- Lightly coat centring seat for converter (arrow) with

grease

- Caution: With transmission replacement note guide bushings

(1)

20. Clean threads

21. Attach automatic transmission

- Note: 2nd person required

- Bolt in bolt

- Lift engine

22. Remove KM-910

|

|

23. Fasten automatic transmission

- At cylinder block

- Note: Position coolant pipe, oil filler pipe

- Tighten bolts (60 Nm / 44.5 lbf. ft.)

- To oil pan

- Tighten bolts (40 Nm / 29.5 lbf. ft.)

24. Attach torque converter

- Caution: Insert bolts with locking compound. Tighten bolts

evenly (20 Nm / 15 lbf. ft.)

- Tighten bolts (45 Nm / 33 lbf. ft.)

- Install closure plug

25. Attach cables to drive unit

26. Remove drive unit

- From KM-412

- Note: 2nd person required

27. Install drive unit

- Note: 2nd person required

- Position on KM-6168

- Note: Note bearing points

- Detach from workshop crane

- Remove KM-2358

- Attach rear reaction member

- Detach axle shafts

28. Fasten rear reaction member

- Tighten bolt (80 Nm / 59 lbf. ft.)

29. Detach KM-412-3

30. Lower drive unit on cables

31. Replace axle shaft retaining rings

32. Install axle shafts

- Note: Drive in at friction weld seam

- Until retaining rings engage

- Tie up axle shafts

33. Detach engine transport shackle

34. Attach exhaust manifold

- Replace gasket

- Replace nuts

- Tighten nuts (22 Nm / 16 lbf. ft.)

35. Attach exhaust manifold heat shield

- Tighten bolts (8 Nm / 6 lbf. ft.)

36. Attach alternator

- Tighten bolts

- To cylinder block (35 Nm / 26 lbf. ft.)

- To alternator shackle (20 Nm / 15 lbf. ft.)

37. Attach engine wiring harness

37. Attach intake manifold support

- Connect ground cable.

- Tighten bolts

- Intake manifold (20 Nm / 15 lbf. ft.)

- Cylinder block (35 Nm / 26 lbf. ft.)

|